2

EN

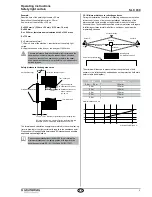

SLC 430

Operating instructions

Safety light curtain

The safety switchgear must exclusively be used in accordance with the

versions listed below or for the applications authorised by the manufac-

turer. Detailed information regarding the range of applications can be

found in the chapter "Product description".

1.5 General safety instructions

The user must observe the safety instructions in this operating instruc-

tions manual, the country-specific installation standards as well as all

prevailing safety regulations and accident prevention rules.

Further technical information can be found in the Schmersal

catalogues or in the online catalogue on the Internet: www.

schmersal.net.

The information contained in this operating instructions manual is provi-

ded without liability and is subject to technical modifications.

The entire concept of the control system, in which the safety

component is integrated, must be validated to EN ISO 13849-

2.

There are no residual risks, provided that the safety instructions as well

as the instructions regarding mounting, commissioning, operation and

maintenance are observed.

Additional measures could be required to ensure that the electro-sensi-

tive device does not present a dangerous breakdown, when other forms

of light beams are available in a special application (e.g. use of wireless

control devices on cranes, radiation of welding sparks or effects of

stroboscopic lights).

1.6 Warning about misuse

In case of inadequate or improper use or manipulations of the

safety switchgear, personal hazards or damage to machi-

nery or plant components cannot be excluded. The relevant

requirements of the standards EN ISO 13855 (successor of

EN 999) and EN ISO 13857 must be observed.

1.7 Exclusion of liability

We shall accept no liability for damages and malfunctions resulting from

defective mounting or failure to comply with this operating instructions

manual. The manufacturer shall accept no liability for damages resul-

ting from the use of unauthorised spare parts or accessories.

For safety reasons, invasive work on the device as well as arbitrary re-

pairs, conversions and modifications to the device are strictly forbidden;

the manufacturer shall accept no liability for damages resulting from

such invasive work, arbitrary repairs, conversions and/or modifications

to the device.

2. Product description

2.1 Ordering code

This operating instructions manual applies to the following types:

SLC 430-E/R➀-30-RF-SYS

No. Option

Description

➀

xxxx

Protection field heights in mm available

lengths:

0236, 0460, 0684, 0908,

1132, 1356, 1580, 1804

Only if the information described in this operating instructions

manual are realised correctly, the safety function and therefo-

re the compliance with the Machinery Directive is maintained.

2.2 Special versions

For special versions, which are not listed in the order code below 2.1,

these specifications apply accordingly, provided that they correspond to

the standard version.

2.3 Included in delivery and accessories

2.3.1 Accessories included in delivery

Sensor E and sensor R with mounting accessories,

Safety monitoring module NSR-0605,

Cable set KA-0610 (cable length 5 m)

2.3.2 Optional accessory

Connecting cable for emitter and receiver

Item num-

ber

Description

Description

Length

1207718

KA-0610

Female connector M8, 4-pole 5 m

1207719

KA-0611

Female connector M8, 4-pole 10 m

Profile for emitter/receiver

Item num-

ber

Description

Profile 40 x 40 mm

Length

1207720

MS-1501

SLC 430-E/R0236-30

467.5 mm

1207721

MS-1502

SLC 430-E/R0460-30

691.5 mm

1207722

MS-1503

SLC 430-E/R0684-30

915.5 mm

1207723

MS-1504

SLC 430-E/R0908-30

1139.5 mm

1207724

MS-1505

SLC 430-E/R1132-30

1363.5 mm

1207725

MS-1506

SLC 430-E/R1356-30

1587.5 mm

1207726

MS-1507

SLC 430-E/R1580-30

1811.5 mm

1207727

MS-1508

SLC 430-E/R1804-30

2035.5 mm

2.4 Destination and use

The SLC is a non-contact, self-testing safety guard, which is used for

the protection of hazardous points, hazardous areas and machine

access . If one or more light beams are interrupted, the hazardous

movement must be stopped.

The user must evaluate and design the safety chain in ac-

cordance with the relevant standards and the required safety

level.

2.5 Technical data

Standards:

EN 61496-1; CLC/TS 61496-2;

EN ISO 13849; EN 62061

Material of the enclosure:

Aluminium

Number of beams:

8 … 64 beams

Protection field heights:

236 mm - 1804 mm

Detection ability for test bodies:

30 mm

Range of the protection field:

0.2 … 3.5 m

Response time:

50 ms

Rated operating voltage:

22-30 VDC or 18-25 VAC

Operating current:

< 300 mA

Wave length of the sensor:

880 nm

Extraneous light insensitivity:

50,000 Lux

Safety outputs (OSSD1, OSSD2):

Relay contact positive action

Switching voltage:

250 V

Switching current:

4 A

Signalling output:

Switching voltage:

42 V

Switching current:

4 A

Load capacity:

2 µF

Load inductance:

2 H

Admissible conduction resistance between OSSD and load:

10 Ω

Test input:

Input voltage HIGH:

30 VDC

Input voltage LOW:

18 VDC

Signal length:

> 100 ms

Input restart interlock (manual reset)

Input voltage HIGH:

30 VDC

Input voltage LOW:

18 VDC

Signal length:

> 200 ms

Function SLC 430

:

Protective mode, restart interlock (manual reset),

contactor control

LED indications Sensor E:

Sensor E active