3

EN

SLC 430

Operating instructions

Safety light curtain

LED indications sensor R:

OSSD ON, OSSD OFF, restart interlock

(manual reset) enabling

Sensor connection:

M8 x 1, 4-pole shielded female connector;

cable length 5m

Safety-monitoring module connection:

Removable screw terminal

block

Ambient temperature:

0° C ... +50° C

Storage temperature:

−10° C ... +70° C

Synchronisation:

RS 485 BUS

Protection class:

IP65 (IEC 60529)

Resistance to vibrations:

10 … 55 Hz to IEC 60068-2-6

Resistance to shock:

10 g; 16 ms; to IEC 60068-2-29

Fuses:

Power supply:

F1: 1.6 A / 250 V T

Output contacts:

F5, F6: 4.0 A / 250 V T

Signalling output:

F7: 4.0 A / 250 V T

Year of construction:

as of 2010 version 1.0

2.6 Safety classification

Standards:

EN ISO 13849-1, EN 62061

PL:

up to e

Control category:

up to 4

PFH value:

1.26 x 10

-8

/h

SIL:

up to 3

Service life:

20 years

2.7 Functions

The system consists of 2 components, the E/R sensors and the NSR-

0605 safety-monitoring module.

The connection between these components is realised through a 4-pole

female connector for the sensor connection. The transmitter and recei-

ver units are supplied with direct-current voltage through the NSR-0605

safety-monitoring module. All system components are connected to the

safety-monitoring module.

The protection field is generated between both sensors E and R, which

each represent a transmitter and a receiver unit. The safety-monitoring

module obtains the signals of the transmitter and receiver units through

a RS-485 BUS connection and makes the corresponding status

available at the output through two safety relays. To trigger a switch-off

command, covering just one light beam will suffice.

The safety light curtain is self-monitoring, i.e. for every fault occuring

in the system either during the self-test or covered by an external test,

the OSSD outputs are disabled. As long as the fault remains active, the

system will remain locked in OFF condition. This locked situation is not

cancelled by switching-off and back on the supply voltage either.

The system has the following features:

• Protective mode

• Restart interlock (manual reset)

• Contactor check

2.7.1 Protective mode / standard operation

The protective mode switches the OSSD outputs to ON state (protec-

tion field not interrupted), without external release of a switching device.

This type of protection generates an automatic restart of the machine if

the protection field is not interrupted.

This operating mode may only be chosen in conjunction with

the restart interlock (manual reset) of the machine.

This operating mode must not be chosen, when persons can

step behind the protection field.

2.7.2 Restart interlock (manual reset) / hold function

In this way, the system is kept in a locked condition after a protection

field interruption, after switch-on or after power off (OSSD's OFF state).

The locking condition will only be cancelled after the protection field is

enabled and an external command device has been actuated. To switch

between normal and hold operation (restart interlock), a slide switch on

the control unit is used.

The command devices (enabling button) must be installed

outside of the hazardous area. The operator must have a

clear view on the hazardous area when actuating the enab-

ling button.

2.7.3 Contactor control (EDM)

The contactor control monitors the controlled switching elements

(auxiliary contacts of the contactors) of both outputs. This monitoring

is realised after each interruption of the protection field and prior to

the restart (enabling) of the outputs. In this way, malfunctions of the

relays are detected, e.g. contact welding or contact spring breakage.

If the light curtain detects a malfunction of the switching elements, the

outputs are locked. (s. Electrical connection)

2.7.4 Testing / external test

The system can trigger a test cycle by means of the external test input.

By applying a signal (+ 24 VDC) at the test output, a complete self-test

is executed. The outputs change to OFF state and are re-enabled after

1.5 s if no fault is detected.

Regardless of the activation of the external test input, a self-test is

cyclically executed within the permissible triggering time of the system.

The condition at the output relays does not change. The system is only

switched off when a fault is detected.

2.7.5 Signalling output / low-voltage safety output

The safety-monitoring module has a potential-free changeover contact

for the connection of a signal lamp. In this way, the signal conditions

OSSD ON and OSSD OFF can be visualised on the machine by means

of an indicator light. The signal lamp can be operated with 12V, 24V or

42V.

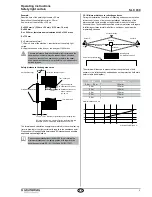

3. Mounting

3.1 General conditions

The following guidelines are provided as a preventive warning notice

to ensure safe and appropriate handling. These guidelines are an

essential part of the safety instructions and therefore must always be

observed and respected.

• The SLC must not be used on machines, which can be

stopped electrically in case of emergency.

• The safety distance between the SLC and a hazardous ma-

chine movement must always be observed and respected.

• Additional mechanical safety guards must be installed so

that the operator has to pass by the protection field to reach

the hazardous machine parts.

• The SLC must be installed so that the personnel always

must be within the detection zone when operating the ma-

chine. An incorrect installation can lead to serious injuries.

• Never connect the outputs to +24VDC. If the outputs are

wired to +24VDC, they are in ON state, as a result of which

they are unable to stop a hazardous situation occuring on

the application/machine.

• The safety inspections must be conducted regularly.

• The SLC must not be exposed to inflammable or explosive

gasses.

• The connecting cables must be connected in accordance

with the installation instructions.

• The fixing screws of the end caps of the mounting angle

must be firmly tightened.