7

EN

SLC 430

Operating instructions

Safety light curtain

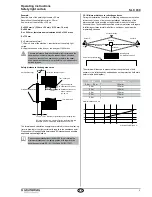

4. Electrical connection

UND

ODER

COM

MAX. 1,6A

MAX. 4A

MAX. 4A

MAX. 4A

L1

L1

L2

L1

L2

*)

*)

VDE 0551

18-21 VAC

22-30 VDC

VDE 0551

MAX. 42 VDC/VAC

15-48 VDC

15-30 VAC

1

2

3

4

5

6

7

1

2

1

2

B

A

Sch

.

B

A

Sch

.

Power supply

Output 1

Signalling output

Output 2

Sensor E

Sensor R

Hold function Test input

*) Spark suppression

OR

AND

Spark suppressors are imperatively required in case of

inductive loads! They must be switched parallel to the

inductance. A circuit parallel to the output contact is not

permissible! When diodes are used as spark suppressors,

switch-off will be delayed.

Approximate values for spark suppressors

Operating voltage

R

C

110 up to 230 V

220 Ω

0.22 µF

24 up to 48 V

100 Ω

2.2 µF

R

C

Operating

voltage

Output

contact

Consumer,

contactor

To avoid contact overload, the output circuits (output 1 / out-

put 2) are individually fused. The maximum current-carrying

capacity is 4 A, 250 VAC. Both safety outputs must not be

wired in series! They must be wired 2-channel to the machi-

ne control. In addition to both main outputs output 1 / output

2, a signalling output is available. This is a potential-free

switching output, which can be switched as power-to-lock

either as power-to-unlock contact. In this way, the signalling

output is used for the logical query of the protection field

status. The current-carrying capacity is 4 A / 42 V.

4.1 Standard operation (protective mode) with contactor control

*

*

*

K1

K1

H

N

K1

K1

K2

K2

K2

K2

Safety monitoring module

Test input

Output 1

Output 2

Machine switch-off

circuit

* RC member for alterna-

ting-current voltage supply

When the test input is wired, the restart time is approx. 1.5

s after enabling of the protection field.

4.2 Restart interlock (manual reset) (hold function) with contac-

tor control

*

*

*

K1

H

N

K1

K1

K2

K2

K2

Safety monitoring module

Input hold

function

Output 1

Output 2

Machine switch-off

circuit

* RC member for alterna-

ting-current voltage supply

The downstream realys K1 and K2 must have positive-action

contacts.