8

EN

SLC 430

Operating instructions

Safety light curtain

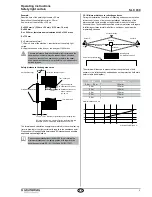

Cable screen at mounting angle

The ground connection laid together with the connecting cables must

be connected as shown to the E and R sensors through the fixation

part.

Connecting cable

KA-0610/0611

Sensor E/R

Fixing part

Earth connection

4.3 Connector configuration

Safety monitoring module NSR-0605

Description

PIN

Meaning

Power supply

V 1

V 2

Sch.

Connections 1, 2, 3 (connected)

Connections 4, 5, 6 (connected)

GROUND

Sensors E / R

+

-

B

A

Sch.

Supply voltage for sensor (brown)

0V for sensor (green)

Data signal for RS-485 bus (yellow)

Data signal for RS-485 bus (white)

Cable sheathing (black)

Signalling output AND

OR

COM

Switching signal ON - no interruption of

the beams, no system failure

Switching signal OFF - beams interrup-

ted or system failure

common switching contact

Input hold func-

tion

+

-

Connection for command device to

suppress the holding function

Connection for command device to

suppress the holding function

Test input

+

-

Input signal to trigger the system test

Input signal to trigger the system test

Output 1

1

2

Safety output OSSD 1, potential-free

NO contact

Output 2

1

2

Safety output OSSD 2, potential-free

NO contact

Power supply Output 1

Signalling output

Output 2

Sensor E Sensor RHold function

Test input

V1

V2

UND

DER

COM

Sch.

1 2

1 2

+ – B A Sch. + – B A Sch.

+ –

+ –

Connection for the E / R sensors:

Description

PIN

Color of the cable

Sensors E / R

+

BN (brown)

-

GR (green)

B

YE (yellow)

A

WH (white)

Sch.

BK (black)

+

-

B

A

Sch.

5. Set-up and maintenance

5.1 Check before start-up

Prior to start-up, the following items must be checked by the responsib-

le person.

1. Starting hazardous machine parts must be impossible as long as a

body part of a person is inside of the protection field of the BWS.

2. The actuation of the BWS (protection field interruption) during the

hazardous stage of the machine operation must cause the hazardous

parts to be stopped or, where appropriate, to change to a different

safe state before they can be reached by a body part of a person. It

must be impossible to restart the hazardous parts before the BWS

has completely returned to its normal state and the machine control

elements have been reactuated.

3. Check the machine to ensure that there are no other mechanical

or structural aspects preventing the machine from being stopped or

from switching to a different, safe state through a switching command

of the BWS.

4. Examine and check the machine control and the connections to the

BWS to make sure that no changes have been made, which have

a negative impact on the system and that suitable and appropriate

changes have been adequately registered.

Switch the SLC on and check the operation in the following way:

The component performs a system test after the operating voltage has

been switched on. After that, the outputs are enabled (if the protection

field is not interrupted). The LED "OSSD ON" of the receiver is on.

In case of incorrect functioning, please follow the instructions

listed in the chapter Fault diagnostic.

5.2 Maintenance

Do not use the SLC before the next inspection is termina-

ted. An incorrect inspection can lead to serious and mortal

injuries.

Conditions

For safety reasons, all inspection results must be archived. The ope-

rating principle of the SLC and the machine must be known in order to

be able conducting an inspection. If the fitter, the planning technician

and the operator are different persons, please make sure that the user

has the necessary information at his disposal to be able conducting the

maintenance.

5.3 Regular check

A regular visual inspection and functional test, including the following

steps, is recommended:

1. The component does not have any visible damages.

2. The optics cover is not scratched or soiled.

3. Hazardous machinery parts can only be accessed by passing

through the protection field of the SLC.

4. The staff remains within the detection area, when works are conduc-

ted on hazardous machinery parts.

5. The safety distance of the application exceed the mathematically

calculated one.

Operate the machine and check whether the hazardous movement

stops under the hereafter-mentioned circumstances.

6. Hazardous machine parts do not move when the protection field is

interrupted.