9

EN

SLC 430

Operating instructions

Safety light curtain

7. The hazardous machine movement is immediately stopped, when

the protection field is interrupted with the test rod immediately before

the sensor E, immediately before the sensor R and in the middle

between the sensor E and R.

8. No hazardous machine movement when the test rod is within the

protection field.

9. Gefährliche Maschinenbewegung kommt zum Stillstand, wenn die

Spannungsversorgung des SLC ausgeschaltet wird.

5.4 Half-yearly inspection

The following items must be checked every six months or when a ma-

chine setting is changed.

1. Machine stops or does not inhibit any safety function.

2. No machine modification or connection change, which affects the

safety system, has taken place.

3. The outputs of the SLC are correctly connected to the machine.

4. The total response time of the machine does not exceed the respon-

se time calculated during the first putting into operation.

5. The cables, the connectors, the caps and the mounting angles are in

perfect condition.

5.5 Cleaning

If the optics cover of the sensors is extremely soiled, the OSSD outputs

can be disabled. Clean with a clean, soft cloth with exercising pressure.

The use of agressive, abrasive or scratching cleaning agents,

which could attack the surface, is prohibited.

6. Diagnostic

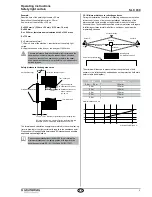

6.1 LED status information

GN

YE

RD

Sensor R

Function

LED

Description

Restart interlock

(manual reset)

yellow Signal request by external com-

mand device (pushbutton)

OSSD OFF

red

Safety outputs OFF state

OSSD ON

green

Safety outputs ON state

OR

Sensor E

Function

LED

Description

Transmitter ON orange Sensor E active

6.2 Optical and acoustic signals in the control unit

The control unit includes an acoustic signal generator (buzzer) as well

as multiple LED's.

The LED's n° 1, 2 and 3 (green) are permanently on when the operating

voltage is present. The LED's 4 and 6 (yellow) and the LED's 5 and

7 (red) show the respective system condition. The acoustic signal is

activated or deactivated by means of the buzzer switch.

The following tables show the different indication types for the system

conditions. The acoustic signal however is only emitted, when the

buzzer is switched on.

NSR-0605

2

1

3

5

4

6

7

F1

F5

F6

F7

H

N

ON

H - Hold function

N - Normal function

Service

fuse

Buzzer switch

Function switch

Buzzer

OFF

6.2.1 Protective mode / standard operation

Status of the protection field

no interruption

continuous interruption

red LED's

(5; 7)

flashing

flashing

yellow

LED‘s (4; 6)

continuously on

off

acoustic

signal

none

short interval

6.2.2 Mode of operation restart interlock (manual reset) / hold

function

A) Everytime the operating voltage is switched on

Start interlock active

red LED's

(5; 7)

continuously on

yellow

LED‘s (4; 6)

off

acoustic

signal

constant

The system waits for the command device to be actua-

ted. For the system condition OSSD's ON, the protection

field must be permanently clear after the actuation of the

command device (hold function input) for 300 ms. If the pro-

tection field is clear (no IR beam interrupted), the system is

enabled. If not, the LED's 4, 6 (yellow) will be off, the LED"s

5, 7 (red) will be permanently on and a constant acoustic

signal is emitted.

B) In operation

Status of the protection field

no interruption

continuous or previous inter-

ruption

red LED's

(5; 7)

flashing

continuously on

yellow

LED‘s (4; 6)

continuously on

off

acoustic

signal

none

constant