11

SLG440

Operating instructions

Safety light grids

EN

Optional accessories

MSD5 spacer

The kit consists of 2 spacers The spacers must be used in case of

vibrations

M4

10

8

33

7,7

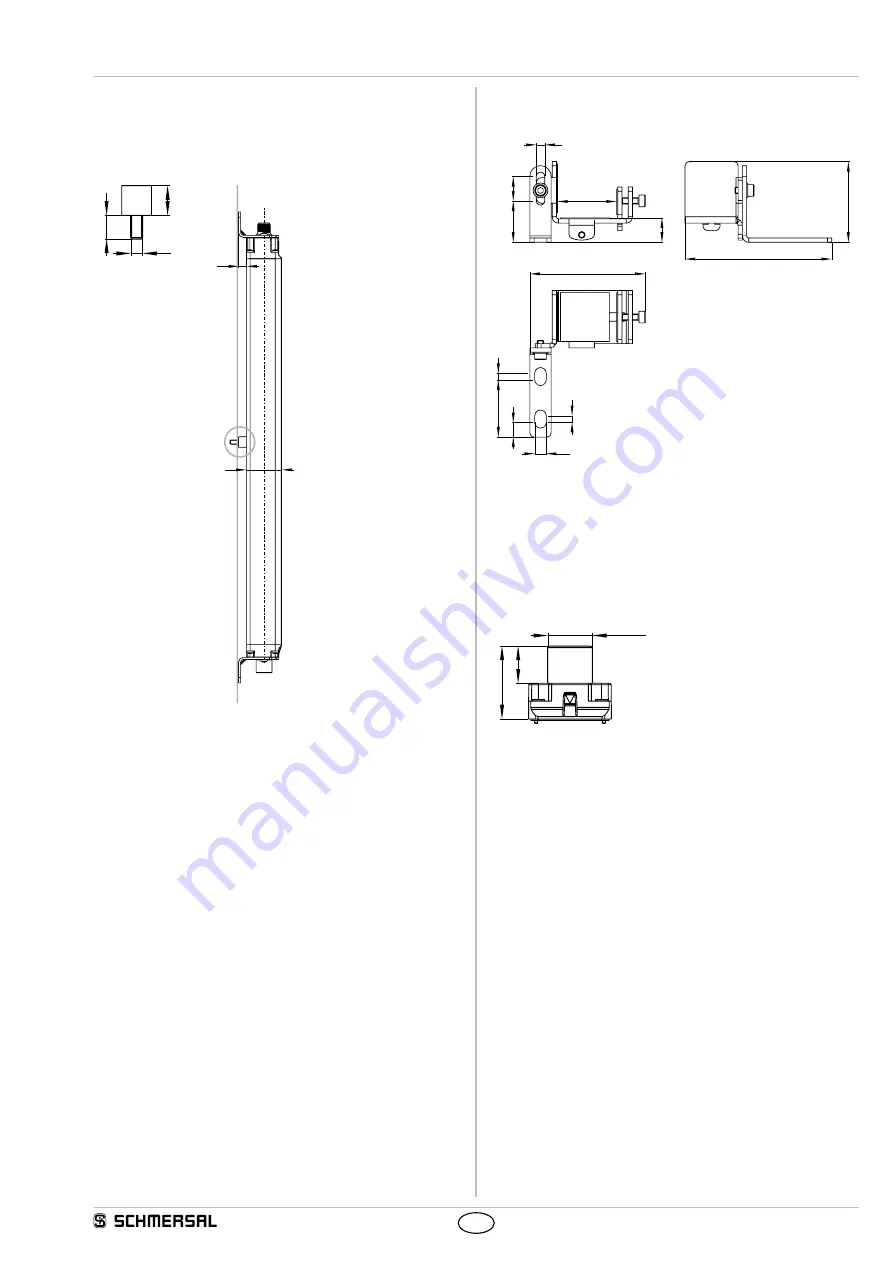

Centre support MS-1110

Mounting kit consists of 2 steel angles and 4 spacers for central fixing

4

27,8

11,5

19,5

11,5

54,3

69

38

5,5

3

27

3

7

Integrated status indication

The status indication at the receiver indicates the switching condition

of the outputs OSSD1 and OSSD2 and the function restart interlock /

setup

Green = outputs H-signal 24V

Red

= outputs L-signal 0V

Yellow = setting mode / restart interlock (manual reset)

24,5

12,5

¤ 15 0,1

±

The integrated status indication

does not

change the mounting dimen-

sion B or the overall length C The overall length of the Ls receiver

changes by 10 mm

MSD4 Vibration damper

Kit consists of: 8 vibration dampers 15 x 20 mm, 8 M5 cylinder head

screws with hexagon socket, 8 spring washers Mounting using MS-

1100

The MSD4 vibration damper kit is recommend to be used for damping

vibrations and oscillations on the SLG440 For applications with higher

mechanical stresses, eg presses, punching machines, we recommend

the MSD4 kit In this way, the availability of the SLG440 is increased