6

Operating instructions

Safety light grids

SLG440

EN

Transmitter parameter setting

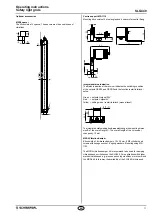

Wiring of the transmitter

- Jumper connection

pin 1 with pin 2

- Jumper connection

pin 3 with pin 4

Pin 1

Pin 2

+ 24V/DC

Pin 3

Pin 4

0V/DC

The response time of the system is increased when beam

coding A is used To this end, the safety distance must be

adjusted Refer to chapter: Response time

2.11 Parameter setting

The parameter setting of the SLG440 enables the individual adjustment

of the desired functionality to the application

Parameter display (7-segment display)

A = parameter active

- = parameter not active

S.

= save the current configuration

C.

= delete the current configuration, new configuration = factory setting

n = unavailable (unauthorised setting, refer to Parameter setting infor-

mation)

d.

= diagnostic/setting mode

Parameter selection

Selection, change and acceptance of the parameters by means of the

command device pushbutton S1:

- Switch to parameter setting Px briefly press the button

01 … 15 sec

- Change parameter setting Px

press button 25 … 6 sec

- Save

S.

/ Factory setting

C.

press button 25 … 6 sec

Procedure

1) For the parameter setting, the receiver must be isolated from the

operating voltage In de-energised condition, the following jumper

connection and the pushbutton S1 must be connected

Freigabe WA

DOUT

EDM

Pin 8

Pin 6

Pin 1

S 1

+ 24 VDC

Release

restart interlock

Wiring of the receiver

• Jumper connection from DOUT (Pin 6) to EDM (Pin 8)

• Connection of the command device pushbutton S1 (+24 VDC) on

Pin 1 (restart interlock)

• Possible jumper connections from Pin 5 to Pin 6 or Pin 1 to Pin 6 must

be removed If the EDM function was activated, the auxiliary contact

of Pin 8 must be removed

2) The receiver switches to parameter setting mode when the operating

voltage is switched on

The operating status is signalled in the following way

7- segment display

●

LED OSSD ON (red) active

●

LED OSSD OFF (green) active

Parameter setting

1) When S1 is briely pressed, the display shows

repeatedly

- (Parameter P 1 not active, factory setting)

2) Select the desired parameter by means of command device S1

(briefly press the button)

3) Select the desired parameter by means of the command device

(press the button for a long time)

1 Push button (approx 25 seconds)

➔

-

flashes (parameter not active)

2 Enable button when

➔

A

static (parameter active)

4) Save the new configuration with the parameter Save

S.

(push the

button for a long)

1 Actuate button (approx 25 seconds)

➔

S.

lashes

2 Enable button when

➔

S.

static

3 Automatic restart

➔

"segment circulation"

then

P

is displayed (saving operation successful)

If no restart takes place (

S.

), the saving operation has not been

successful (ie the parameter changes have not been saved)

The procedure 4 (1 to 3) must be repeated

All parameters can be reset to the factory setting using parameter

C.

(clear/delete)

1) Press the button approx 25 seconds)

➔

C.

flashes

2) Enable the button when

➔

C.

static

3) Automatic restart

➔

"Segment circulation", then

P

is displayed

(all parameters have been deleted)

Return to normal operating mode

1 Switch off the operating voltage at the receiver

2. Remove jumper connection at the receiver DOUT (Pin 6) and

EDM (Pin 8)

3 Select the desired operating mode (jumper connections)

4 Switch operating voltage on

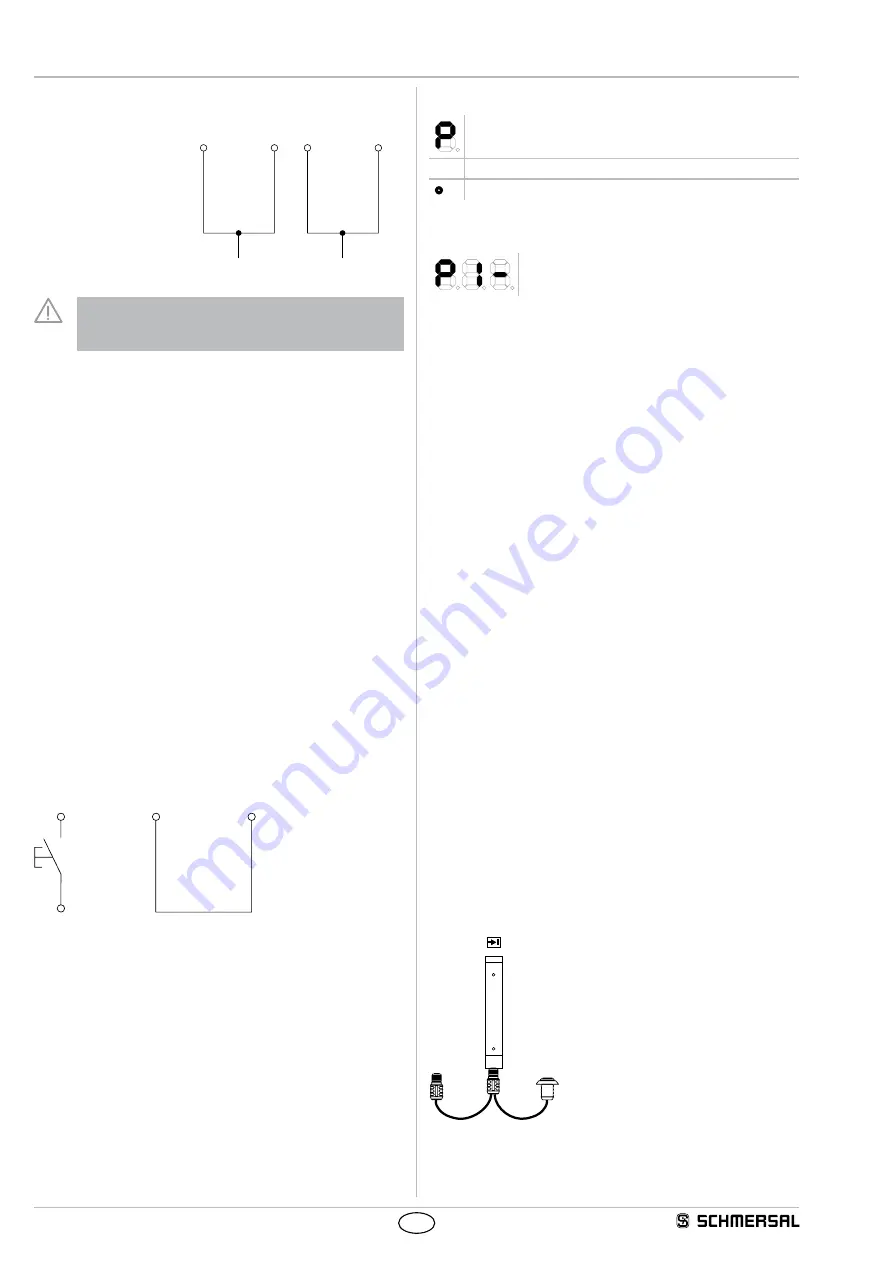

Adapter cable for parameter setting

If the wiring for the parameter setting of the receiver is not acces-

sible, the KA-0974 adapter cable can be used as an alternative The

adapter cable is connected between the connecting cable and the

cable connector of the receive The parameters are set by means of the

command device (pushbutton), as described in the parameter setting

After the parameters have been set, the KA-0974 is removed and the

connecting cable is connected to the receiver

1

2

Key

1 = Connecting cable Receiver

2 = Command device pushbutton

for release