12

Operating instructions

Safety light grids

SLG440

EN

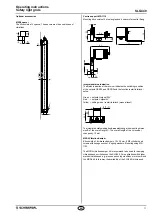

4. Electrical connection

4.1 Wiring example

5

Kn 1

Kn 2

S 1

K 1

K 2

6

1

8

2

7

3

4

Schüt

zkontr

olle

(RD)

COD

1(WH)

COD

2

(BK)

0

V

DC

(BU)

OSSD

1(GN)

OSSD

2

(YE)

+24

V

DC

(BN)

Erdung

E 1

2

4

3

1

+24

V

DC

(BN)

0

V

DC

(BU)

COD 1 (WH)

COD 2 (BK)

Release no 2 (GY)

Bridge 1

DOUT

(PK)

+24 VDC (BN)

0 VDC (BU)

Release/restart interlock (WH)

Bridge 2

+24 VDC (BN)

Contactor control (RD)

OSSD 2 (YE)

OSSD 1 (GN)

0 VDC (BU)

Earth connection

Restart interlock (manual reset) (bridge 1)

By bridging restart 2 (pin 5) and DOUT (pin 6), the restart interlock

(manual reset) is activated Connect S1 to Pin1

Protective mode / Automatic active (bridge 2)

By bridging DOUT (Pin 6) and enable restart (Pin1), the protective

mode is activated

Don't connect S1.

K1, K2

Relay for processing the switching outputs

OSSD 1,OSSD 2

Kn1, Kn2

Auxiliary contacts of the last switching relay (optional)

signals at input EDM (Pin 8)

Only to be connected when the contactor control is

activated.

S1

Command device pushbutton for restart (optional)

E1

Power supply 24 VDC ± 10%