15

SLG440

Operating instructions

Safety light grids

EN

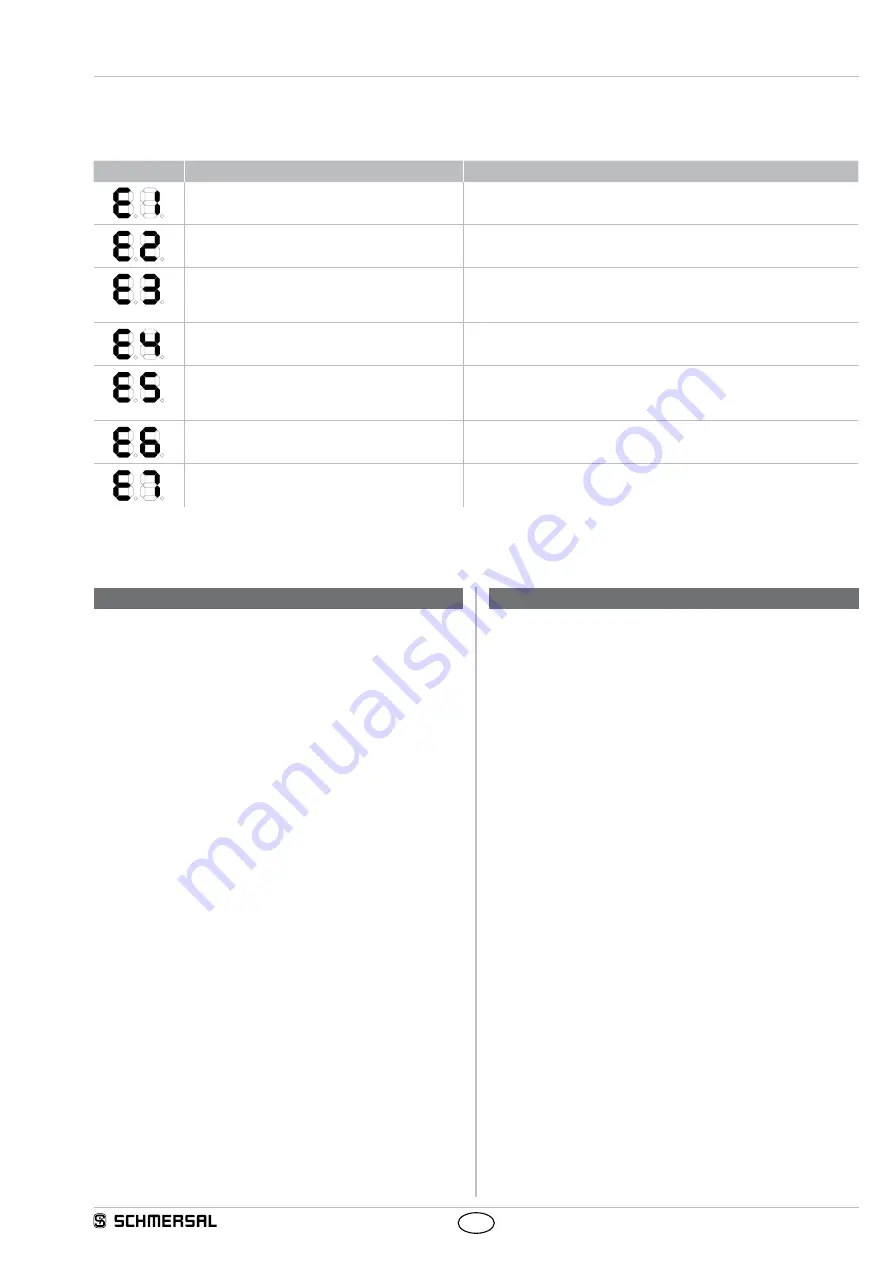

6.2 Fault diagnostic

The light grid performs an internal self-test after the operating voltage is switched on and the protection field is enabled When a fault is detected, an

error number eg E1 is displayed at the receiver Each fault display is followed by a one-second delay

Status display

Fault feature

Action

Wiring error, operating mode not defined

(automatic or restart mode)

Check all connections at the receiver,

Jumper connection 1 or jumper connection 2 present?

Supply voltage

UB = 24V/DC+/- 10%, check voltage source and primary voltage, note: after

the fault message E2 has been displayed three times, a reset is executed

Error output (e), OSSD1 or OSSD2

Check the connections of both outputs, short-circuit of both OSSD,

connection to level 0V or 24V, deactivate external (relay) cross-wire short

monitoring

Contactor control (EDM)

EDM active: check connections of both NC contacts,

EDM not active: check level at Pin 8, open input

Beam blanking

Check the blanking area(s) of fixed or floating objects with the selected

parameter setting, fault elimination - repeat configuration in the parameter

setting, possibly adjust P 1, P 2, P 3

Configuration error in parameter setting

Check parameter setting and save/accept with "S" or delete/reset with

"C"

System error

Restart the system, if E 7 display persists, exchange components

The error display is reset after elimination of the error cause and after the receiver has been switched back on

The error indication displays a 3-digit system error code for every 10th display

7. Disassembly and disposal

7.1 Disassembly

The safety switchgear must be disassembled in a de-energised

condition only

7.2 Disposal

The safety switchgear must be disposed of in an appropriate manner

in accordance with the national prescriptions and legislations

8. Appendix

8.1 Contact

Consultancy / Sales

K. A. Schmersal GmbH & Co. KG

Möddinghofe 30

D-42279 Wuppertal

Phone +49 (0) 202 64 74 -0

Fax +49 (0) 202 64 74- 100

You will also find detailed information regarding our product variety

on our website: www schmersalcom

Repair handling / shipping

Safety Control GmbH

Am Industriepark 11

D-84453 Mühldorf/ Inn

Phone +49 (0) 8631-18796-0

Fax +49 (0) 8631-18796-1