3

SLG440

Operating instructions

Safety light grids

EN

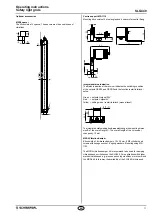

MSD4 Vibration damper

Kit consists of: 8 vibration dampers 15 x 20 mm, 8 M5 cylinder head

screws with hexagon socket, 8 spring washers Mounting using MS-1100

The MSD4 vibration damper kit is recommend to be used for damping

vibrations and oscillations on the SLG440 For applications with higher

mechanical stresses, eg presses, punching machines, we recommend

the MSD4 kit In this way, the availability of the SLG440 is increased

Spacer MSD5

The kit consists of 2 spacers The spacers must be used in case of

vibrations

Integrated status indication

The SLG440 series is also available with integrated status indication

(red/yellow/green) installed onto the receiver (See ordering code)

2.5 Technical data

Standards:

EN 61496-1; EN 61496-2;

EN ISO 13849; EN 62061

Material of the enclosure:

Aluminium

Protection field heights:

500 mm, 800 mm, 900 mm

Detection ability for test bodies:

2 beams with resolution 500 mm *3

3 beams with resolution 400 mm *3

4 beams with resolution 300 mm *3

Range of the protection field:

- Standard

03 … 12 m

- Height range (H)

30 … 20 m

Response time:

- Beam coding (normal)

2 - 4 beams = 10 ms

- Beam coding A

2 - 4 beams = 15 ms

Rated operating voltage:

24 VDC ±10% (PELV) supply unit

I

max

20 A, to EN 60204

(power drop ≤ 20 ms)

Rated operating current:

250 mA max + 2 x 025 A each OSSD

Wavelength of the infrared radiation:

880 nm

Transmitter, infrared emitted radiation

- to DIN EN 12198-1:

Category 0

- to DIN EN 62471:

free group

Safety outputs

OSSD1, OSSD2:

2 x short-circuit proof PNP

semi-conductor outputs

Test impulse cycle OSSD:

750 ms

Test impulse length:

100 µs

Switching voltage HIGH¹:

15 … 264 V

Switching voltage LOW¹:

0 … 2 V

Switching current each OSSD:

0 … 250 mA

Leakage current²:

1 mA

Load capacity:

0 … 22 µF

Load inductance

4

:

0 … 2 H

Admissible conduction resistance between OSSD and load:

2.5 Ω

Admissible conduction resistance of the supply cable:

1.5 Ω

Contactor control (EDM)

Input voltage HIGH (inactive):

11 … 30 V

Input voltage LOW (active):

0 … 20 V

Input current HIGH:

3 … 10 mA

Input current LOW:

0 … 2 mA

Input release restart interlock/restart interlock 2

Input voltage HIGH (active):

11 … 30 V

Input voltage LOW (inactive):

0 … 20 V

Input current HIGH:

3 … 10 mA

Input current LOW:

0 … 3 mA

Functions:

automatic mode, restart interlock,

double reset, contactor control,

beam blanking fixed and floating,

beam coding A

Signal times

Contactor control:

max 500 ms

Restart interlock (manual reset):

50 ms … 15 s, signal

transmission in case of trailing edge

LED indications transmitter:

transmitting, status

LED indications receiver:

OSSD ON, OSSD OFF, restart, signal

reception, blanking, information

Connection:

M12 connector plug with metal thread,

receiver 8-pole, transmitter 4-pole

Ambient temperature:

−25° C … + 50° C;

at −25° C: Reduction of range by −10%

Storage temperature:

−25° C … + 70° C

Interface:

Diagnostics and function setting

Protection class:

IP67 (IEC 60529)

Resistance to vibration:

10 … 55 Hz to IEC 60068-2-6

Resistance to shock:

10 g, 16 ms, to IEC 60028-2-29

Year of construction:

as of 2014 version 20

¹) To IEC 61131-2

²) In case of failure, the leakage current at the most flows to the OSSD

cable The downstream control element must recognise this state as

LOW A safety PLC must detect this state

³) resolution = beam di beam diameter 10 mm

4)

The load induction generates an induced voltage during the

switch-off, which compromises the downstream components

(spark quenching element)

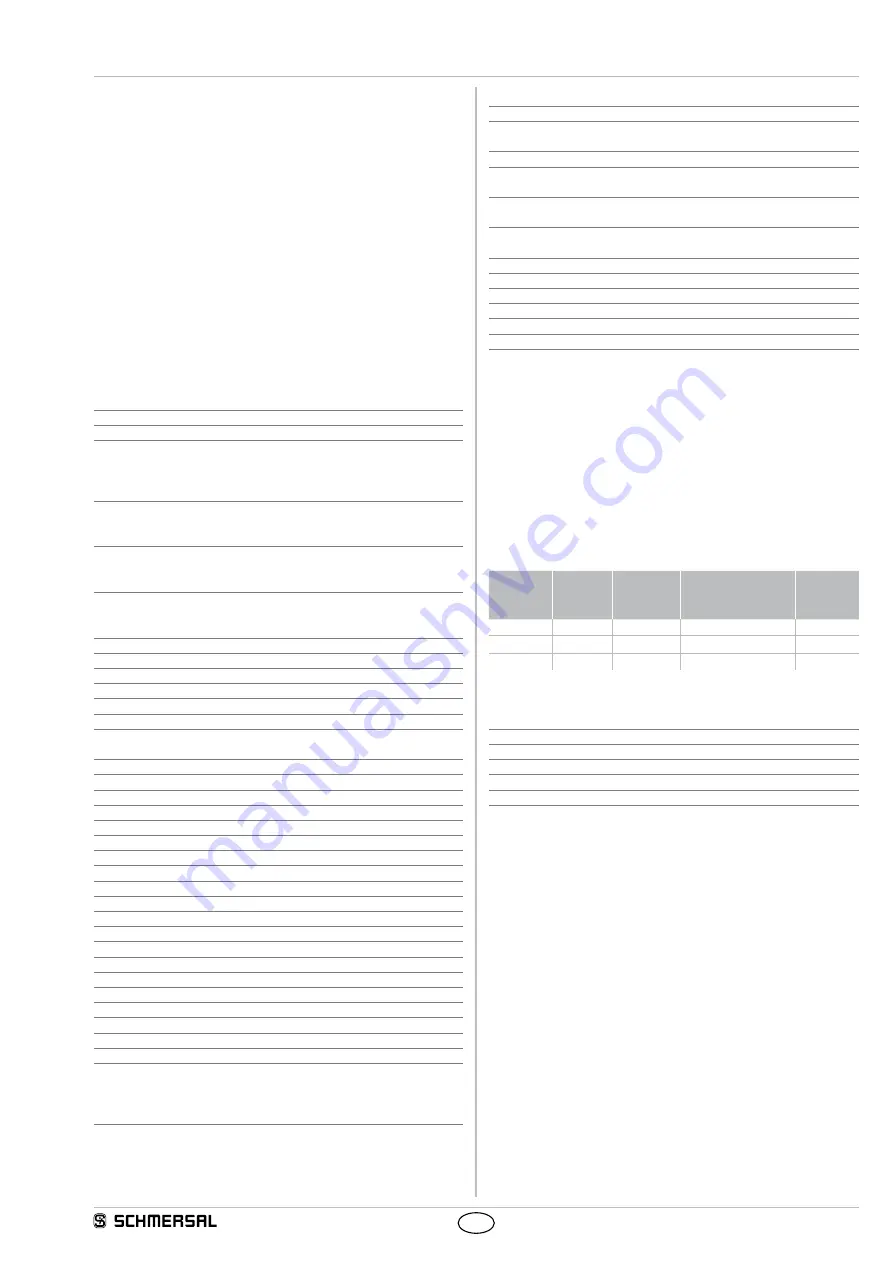

2.6 Response time (reaction time)

The response time depends on the number of light beams and the

beam coding A

Beams

[Number]

Beam

distance

[mm]

Response

time

[ms]

Response time

with beam coding

A [ms]

Weight

[kg]

2

500

10

15

090

3

400

10

15

135

4

300

10

15

150

2.7 Safety classification

Standards:

EN ISO 13849-1, EN 62061

PL:

up to e

Control category:

up to 4

PFH value:

514 x 10

-9

/ h

SIL:

up to 3

Service life:

20 years

2.8 Functions

The system consists of a receiver and a transmitter For the described

functions, no further switching elements are required The diagnostic

and function selection takes place with a command device (key re-

lease), refer to the chapter on parameterisation

The system has the following features:

• Protective mode automatic

(automatic start after release of the protection zone)

• Restart Interlock (manual reset)

• Double acknowledgement/reset

• Contactor control (EDM)

• Beam coding A

• Blanking of movable objects