4

Operating instructions

Safety light grids

SLG440

EN

Factory setting

The system features many functions without needing any additional

devices The following table gives an overview of the possible functions

and the factory settings configuration

Function

Factory setting Configuration

Protective mode,

automatic

not active

External wiring

Restart interlock

(manual reset)

not active

External wiring

Double acknowledgement/

reset

not active

with command device

Blanking of moving

objects

not active

with command device

Contactor control (EDM)

not active

with command device

Beam coding A

not active

with command device

By default neither the restart interlock (manual reset) nor

the protective mode is active One of both operating modes

must be wired in order to enable the OSSD outputs If no

operating mode is selected, the following message is shown:

Status indication E1 + LED OSSD OFF (red)

2.8.1 Protective mode / Automatic

The protective mode switches the OSSD outputs to the ON state

(protection field not interrupted), without external release of a switching

device

Wiring of the receiver

Jumper connection

pin 1 with pin 6

Pin 1

Pin 6

This operating mode generates an automatic restart of the machine if

the protection field is not interrupted

A 24 VDC H-signal at the input of pin 1 leads to a restart of

the system If the 24 VDC H-signal is still present at pin 1

after the self-test, the system switches to setting mode,

see chapter "Setting mode"

This operating mode may only be chosen in conjunction with

the restart interlock (manual reset) of the machine

This operating mode must not be chosen, when persons can

step behind the protection field

2.8.2 Restart Interlock (operation)

The restart interlock (manual reset) prevents an automatic enabling of

the outputs (OSSD's ON state) after switch-on of the operating volt-

age or an interruption of the protection field The system switches the

outputs only to ON state, when an external command device (restart

button) generates an enabling signal at the restart input (receiver)

Wiring of the receiver

- Jumper connection pin 5 with pin 6

- Command device (enabling button)

at pin 1

+24VDC

Pin 5

Pin 6

S1

Pin 1

The command devices (enabling button) must be installed

outside of the hazardous area The operator must have

a clear view on the hazardous area when actuating the

enabling button

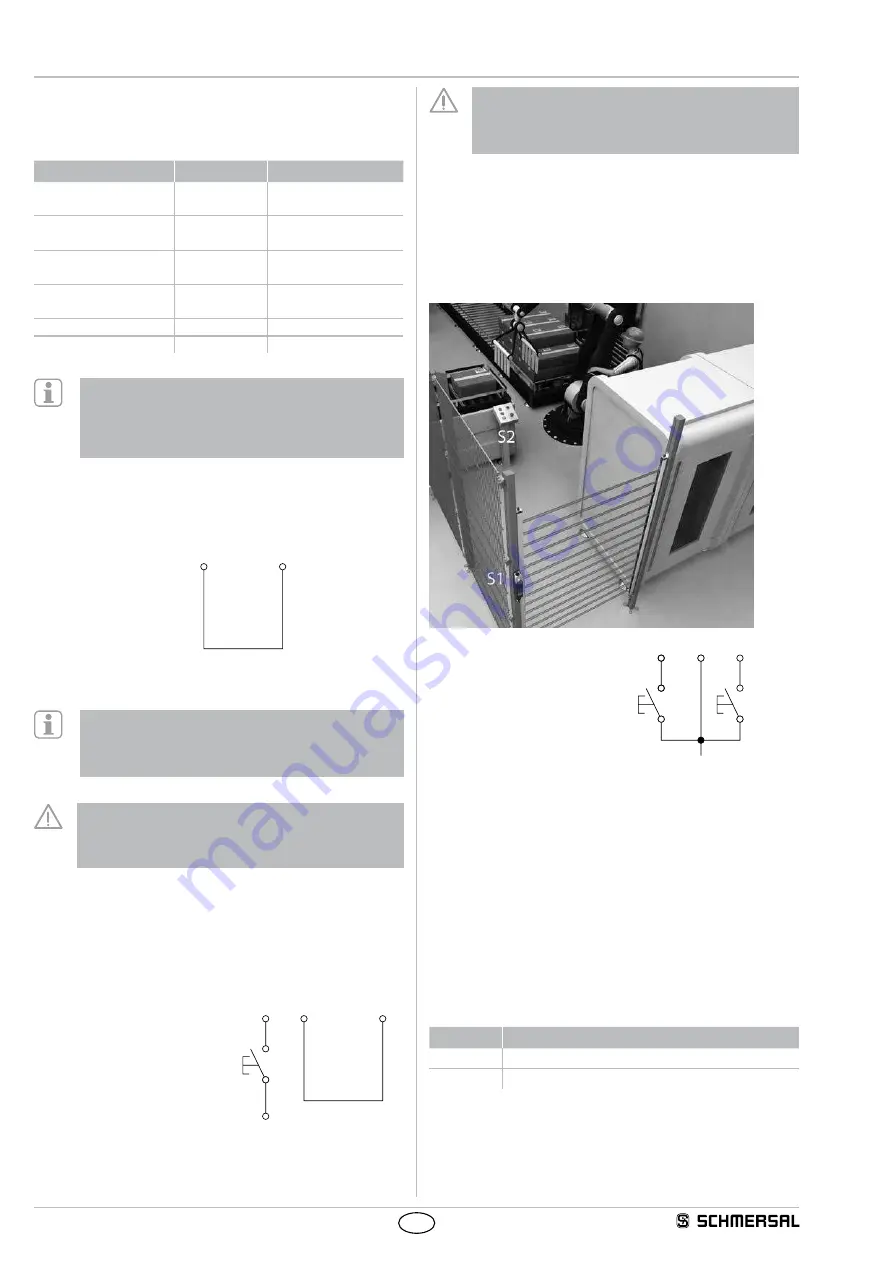

2.8.3 Restart interlock with double acknowledgement/reset

In applications with access monitoring, a complete overview of the

hazardous areas is often not possible; despite that, a reset of the com-

mand device for the restart interlock outside of the hazardous area by

third parties is at all times enabled, although possible persons/operators

are in the invisible area This hazardous situation can be avoided by

means of a double reset, ie integration of two command devices inside

and outside the hazardous area

Wiring of the receiver

- Command device S1 at pin 1

- Command device S2 at pin 5

- Pin 6, no signal (input open)

S1

+24VDC

Pin 1

Pin 2

S2

Pin 5

Specification

The operating mode is available, when the parameter setting -

double reset is activated (P 5) See chapter Parameter setting

Sequence for enabling:

1) Actuate command device inside of the hazardous area (S2) and

leave the hazardous area

2) Go through protected field or interrupt at least one beam, then

release protected field

3) Actuate the command device outside of the hazardous area (S1)

Command device S1 can be reset (acknowledged) within a timeframe

of 2 to 60 seconds after the actuation of S2 If the order or the time

requirement is not respected, the process must be repeated

Signaliling: LED restart (yellow)

Status

Note

On

Release of S2 (restart interlock 2) waiting for signal

Flashing

Release of S1 (restart interlock) waiting for signal