7

SLG440

Operating instructions

Safety light grids

EN

Table Parameter setting

No. Parameter

Status

Note

P 1

not available

n

not available

P 2

not available

n

not available

P 3

Floating blanking 1

light beam

– = not active

1 = 1 beam

Blanking of

one

beam,

only for resolution 300 mm

and 400 mm

P 4

Contactor control/

EDM

– = not active

A = Active

The auxiliary (NC) contacts

are monitored

P 5

Double acknow-

ledgement with com-

mand device restart

interlock N° 2

– = not active

A = Active

Operating mode "Protective

mode with double reset"

restart n° 2"

P 6

Beam coding A

(alternative)

– = not active

A = Active

Activating upon mutual

interference of identical

systems

P 7

Rotating the display

through 180 degrees

– = not active

A = Active

The orientation of the

7 segment display can be

turned through 180 degrees

S.

Save

S

Press button S1 to

save changes

(25 …60 sec)

C.

Clear/delete

C

Press button S1 to

save factory setting

(25 …60 sec)

d.

Diagnostic/

setting mode

d

Switch to setting mode

P 1 and P 2 - not available!

P 6 - Beam coding A must also be set at the transmitter,

refer to chapter Beam coding A

3. Mounting

3.1 General conditions

The following guidelines are provided as preventive warning notices

to ensure a safe and appropriate handling These guidelines are an

essential part of the safety instructions and therefore must always be

observed and respected

•

The SLG must not be used on machines, which can be

stopped electrically in case of emergency

•

The safety distance between the SLG and a hazardous ma-

chine movement must always be observed and respected

•

Additional mechanical safety guards must be installed so

that the operator has to pass by the protection field to reach

the hazardous machine parts

•

The SLG must be installed so that the personnel always

must be within the detection zone when operating the ma-

chine An incorrect installation can lead to serious injuries

•

Never connect the outputs to +24VDC If the outputs are

wired to +24VDC, they are in ON state, as a result of which

they are unable to stop a hazardous situation occurring on

the application/machine

•

The safety inspections must be conducted regularly

•

The SLG must not be exposed to inflammable or explosive

gasses

•

The connecting cables must be connected in accordance

with the installation instructions

•

The fixing screws of the end caps and the mounting angle

must be firmly tightened

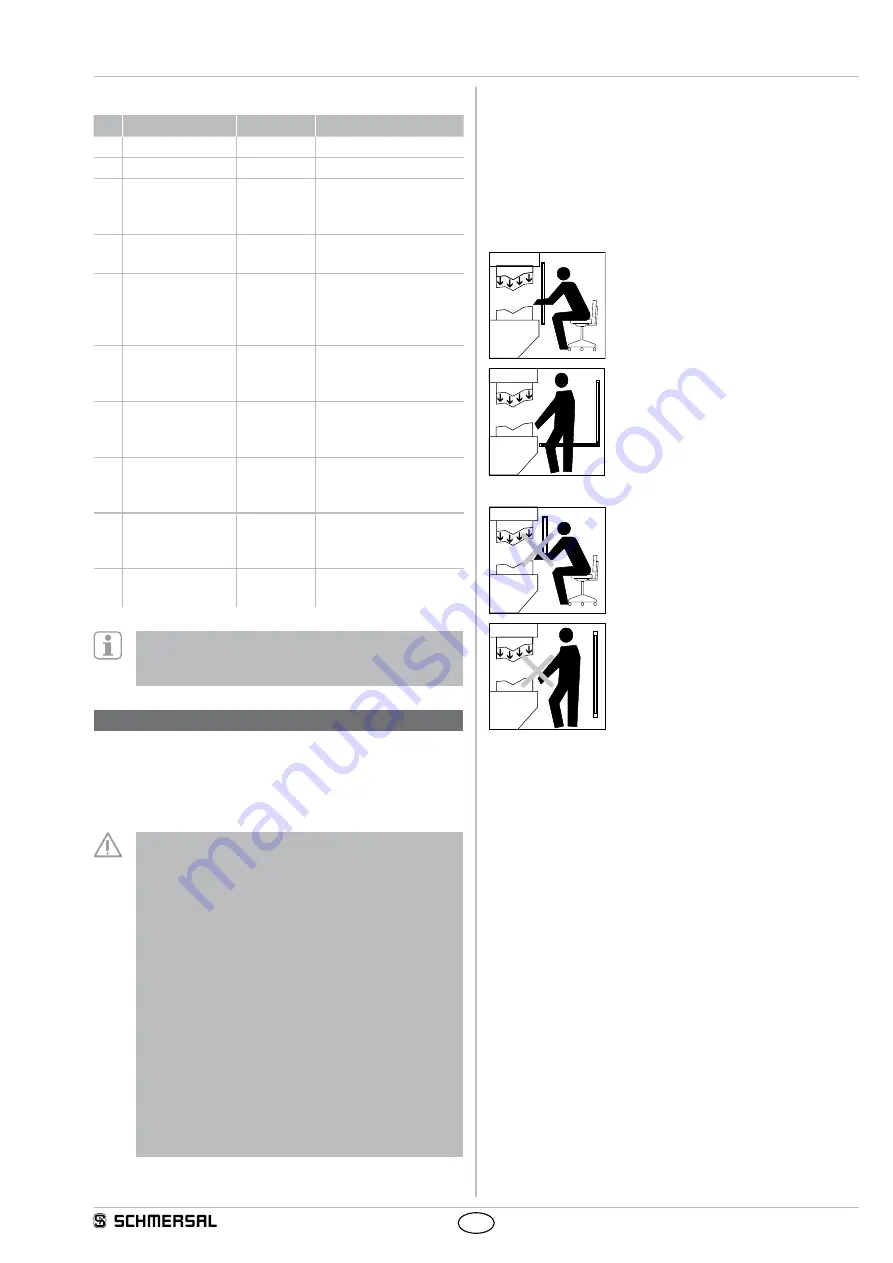

3.2 Protection field and approach

The protection field of the SLG consists only of the individual beams

with a distance of 300, 400 or 500 mm Additional protective devices

must ensure that hazardous machine components can only be reached

after passing through the protection field

The SLG must be installed so that personnel are always located within

the detection zone of the safety device when operating the hazardous

machine parts to be secure

Correct installation

Hazardous machine parts can only be reached

after passing through the protection field

The presence of staff members between the

protection field and hazardous machine parts

must be prevented/avoided (protection against

stepping over)

Unauthorised installation

Hazardous machine parts can be reached

without passing through the protection field

The presence of staff members between the

protection field and hazardous machine parts

is enabled

3.3 Alignment of the sensors

Procedure:

1 Transmitter and receiver must be fitted parallel to each other and at

the same height

2 Choose the operating mode "Automatic" (see chapter Protective

mode/automatic) and switch the operating voltage on

3 The 7-segment display in the receiver shows the current signal qual-

ity/fine setting (signalling, see chapter "set-up mode") for 30 seconds

Rotate the transmitter and then the receiver towards each other until

you have the best possible signal strength of 3 horizontal bars (7

segment display) (note that 2 horizontal bars is sufficient) Fix this

position using the screws to the mounting angleIf the set-up is not

possible within 30 seconds, change to set-up mode (see chapter

"set-up mode") The set-up mode leads to the best possible position-

ing of the sensors through the basic setting (position of the first and

last beam) and the optimisation of with the fine setting (total signal)

Status indication of the LED

OSSD ON (green) is active, signal strength (orange) is not active