4

Operating instructions

Safety-monitoring module

SRB 201ZH

EN

6. Set-up and maintenance

6.1 Functional testing

The safety function of the safety-monitoring module must be tested

The following conditions must be previously checked and met:

1 Correct fixing

2 Check the integrity of the cable entry and connections

3 Check the safety-monitoring module's enclosure for damage

4 Check the electrical function of the connected sensors and their influ-

ence on the safety-monitoring module and the downstream actuators

6.2 Maintenance

A regular visual inspection and functional test, including the following

steps, is recommended:

1 Check the correct fixing of the safety-monitoring module

2 Check the cable for damages

3 Check electrical function

The device has to be integrated into the periodic check-ups

according to the Ordinance on Industrial Safety and Health,

however at least 1 × year.

Damaged or defective components must be replaced.

7. Disassembly and disposal

7.1 Disassembly

The safety-monitoring module must be disassembled in a de-energised

condition only

Push up the bottom of the enclosure and hang out slightly tilted for-

wards

7.2 Disposal

The safety-monitoring module must be disposed of in an appropriate

manner in accordance with the national prescriptions and legislations

8. Appendix

8.1 Wiring examples

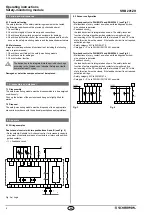

Dual-channel control with two pushbuttons A and B (see Fig. 2)

• Relay outputs: Suitable for 2-channel control, for increase in capacity

or number of contacts by means of contactors or relays with positive-

guided contacts

•

S

= Feedback circuit

L1

L1

S

K1

F3

K2

K1

31

31

23

23

13

13

S21

S21 S22

S22

S12

S12

S11

S11

A2.1

A2.1

A1.1

A1.1

A1

A1

X1

X1

X2

X2

32

24

14

A2

A2

a)

F1

F2

K2

K

A

K

B

K

A

K

B

K

A

K

B

N

Fig 2 a) Logic

8.2 Sensor configuration

Two-hand control to DIN EN 574 and EN 60204-1 (see Fig. 3)

• Malfunctions of every contact as well as earth leakages and cross-

wire shorts are detected

• Feedback circuit

S

:

the feedback circuit is integrated as shown The safety-technical

function of external positive-guided contactors is monitored by a

series-wiring of the NC contacts with the terminals X1 and X2 In idle

state, this circuit must be closed If the feedback circuit is not required,

establish a bridge

• Safety category III/C to DIN EN 574

• Category 4 – PL e to DIN EN ISO 13849-1 possible.

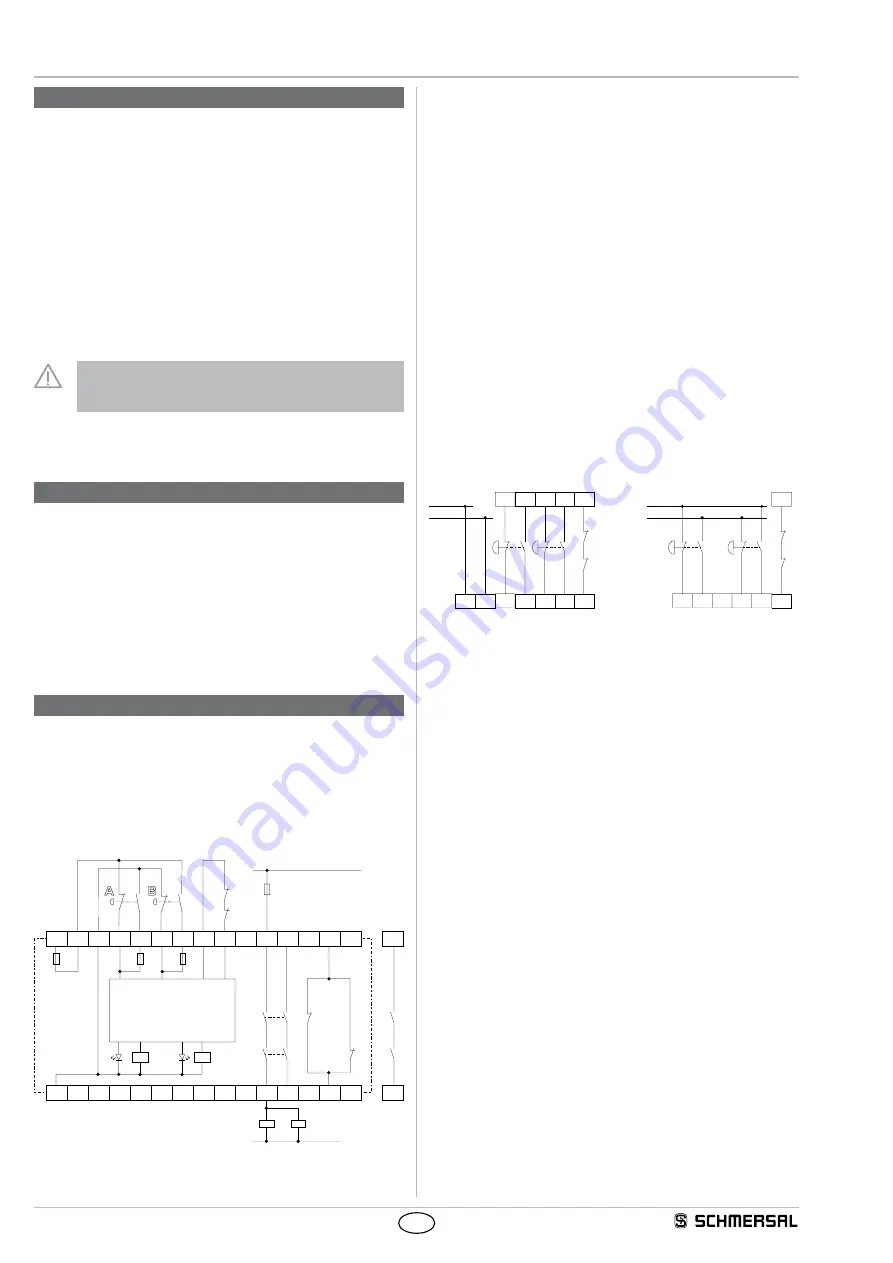

Two-hand control to DIN EN 574 and EN 60204-1 (see Fig. 4)

• Malfunctions of every contact as well as earth leakages and cross-

wire shorts are detected

• Feedback circuit

S

:

the feedback circuit is integrated as shown The safety-technical

function of external positive-guided contactors is monitored by a

series-wiring of the NC contacts with the terminals X1 and X2 In idle

state, this circuit must be closed If the feedback circuit is not required,

establish a bridge

• Safety category III/C to DIN EN 574

• Category 4 – PL e to DIN EN ISO 13849-1 possible.

S11

A2

A1

A1.1

S12

A2.1

S21

A2.1

S22

A1.1

X2

X1

A

0 VDC

24 VDC

B

S

S11

S12

S21 S22

X2

X1

A

0 VDC

24 VDC

B

S

Fig. 3

Fig. 4