4

Operating instructions

Safety-monitoring module

SRB 202CS / SRB 202CS/T / SRB 202CA/T /

SRB 202CA/QT / SRB 202CA / SRB 202CA/Q

EN

L1

K1

K1

K2

K2

K3

K4

42

13

24

X2

S41

S22

S12

A1

24 VDC

J

X1

S31 S32

S42

31

14

A2

F1

UB

K

A

K

B

K

C

K

D

K

C

K

D

a)

K1

K3

K4

K2

32

K3

K4

S

K

B

N

Ui

K

A

K

C

K

D

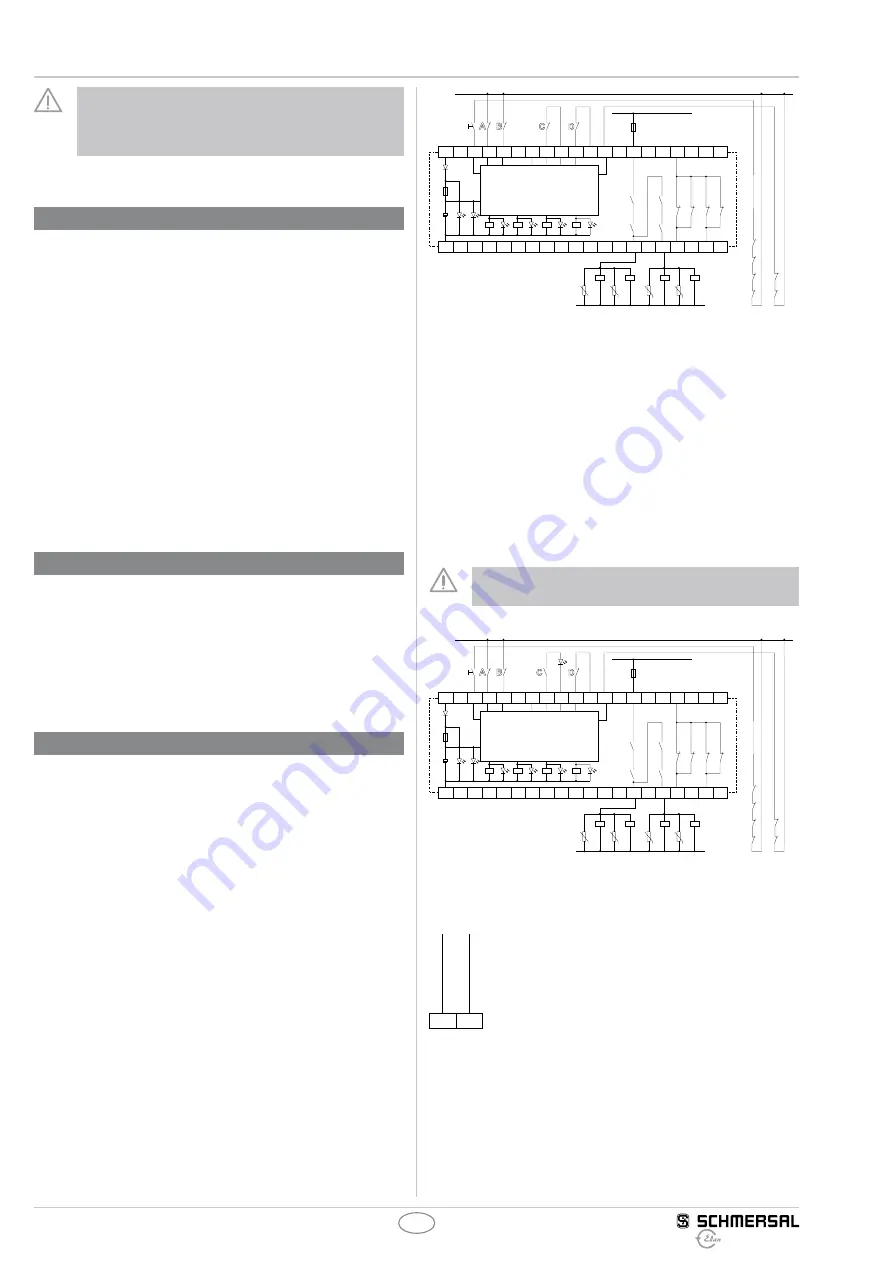

Fig. 2: SRB 202CS, 202CS/T

a) Logic

Dual-channel control, shown for a emergency stop circuit;

with two contacts A and B and a guard door monitor with two

contacts C and D, where at least one is a positive break contact;

with external reset button

J

(related on the switch-off level 1)

(see Fig. 3)

• Relay outputs: Suitable for 2-channel control, for increase in capacity

or number of contacts by means of contactors or relays with positive-

guided contacts.

•

The control system of the emergency stop circuit detects wire breakage

and earth faults (cross-wire shorts in the SRB 202CA/QT and SRB

202CA/Q versions). The control system of the door monitoring circuits

detects wire breakage, earth faults and cross-wire shorts.

•

S

= Feedback circuit

Channel B of SRB 202CA/Q and SRB 202CA/QT: 0 V – S22

(see Fig. 4)

L1

K1

K1

K2

K2

K3

K4

42

13

24

X2

S43

S22

S12

A1

24 VDC

J

X1

S31 S32

S44

31

14

A2

F1

UB

K

A

K

B

K

C

K

D

K

C

K

D

a)

K1

K3

K4

K2

32

K3

K4

S

K

B

N

Ui

K

A

K

C

K

D

Fig. 3: SRB 202CA, 202CA/T, SRB 202CA/Q, SRB 202CA/QT

a) Logic

S12

S22

24 VCC 0 V

Fig. 4

Due to the operating principle of the electronic fuse, the

customer must check that no hazard is caused by an

unexpected restart in circuits without reset button

(automatic reset).

6 Set-up and maintenance

6.1 Functional testing

The safety function of the safety-monitoring module must be tested.

The following conditions must be previously checked and met:

1. Correct fixing

2. Check the integrity of the cable entry and connections

3. Check the safety-monitoring module’s enclosure for damage.

4. Check the electrical function of the connected sensors and

their influence on the safety-monitoring module and the

downstream actuators

6.2 Maintenance

A regular visual inspection and functional test, including the following

steps, is recommended:

1. Check the correct fixing of the safety-monitoring module

2. Check the cable for damages

3. Check electrical function

Damaged or defective components must be replaced.

7 Disassembly and disposal

7.1 Disassembly

The safety-monitoring module must be disassembled in a de-energised

condition only.

7.2 Disposal

The safety-monitoring module must be disposed of in an appropriate

manner in accordance with the national prescriptions and legislations.

8 Appendix

8.1 Wiring examples

Dual-channel control, shown for a emergency stop circuit;

with two contacts A and B and a guard door monitor with two

contacts C and D, where at least one is a positive break contact;

with external reset button

J

(related on the switch-off level 1)

(see Fig. 2)

• Relay outputs: Suitable for 2-channel control, for increase in capacity

or number of contacts by means of contactors or relays with positive-

guided contacts.

•

The control system recognises wire-breakage and earth faults in the

monitoring circuit.

•

S

= Feedback circuit