5

SRB 202CS / SRB 202CS/T / SRB 202CA/T /

SRB 202CA/QT / SRB 202CA / SRB 202CA/Q

Operating instructions

Safety-monitoring module

EN

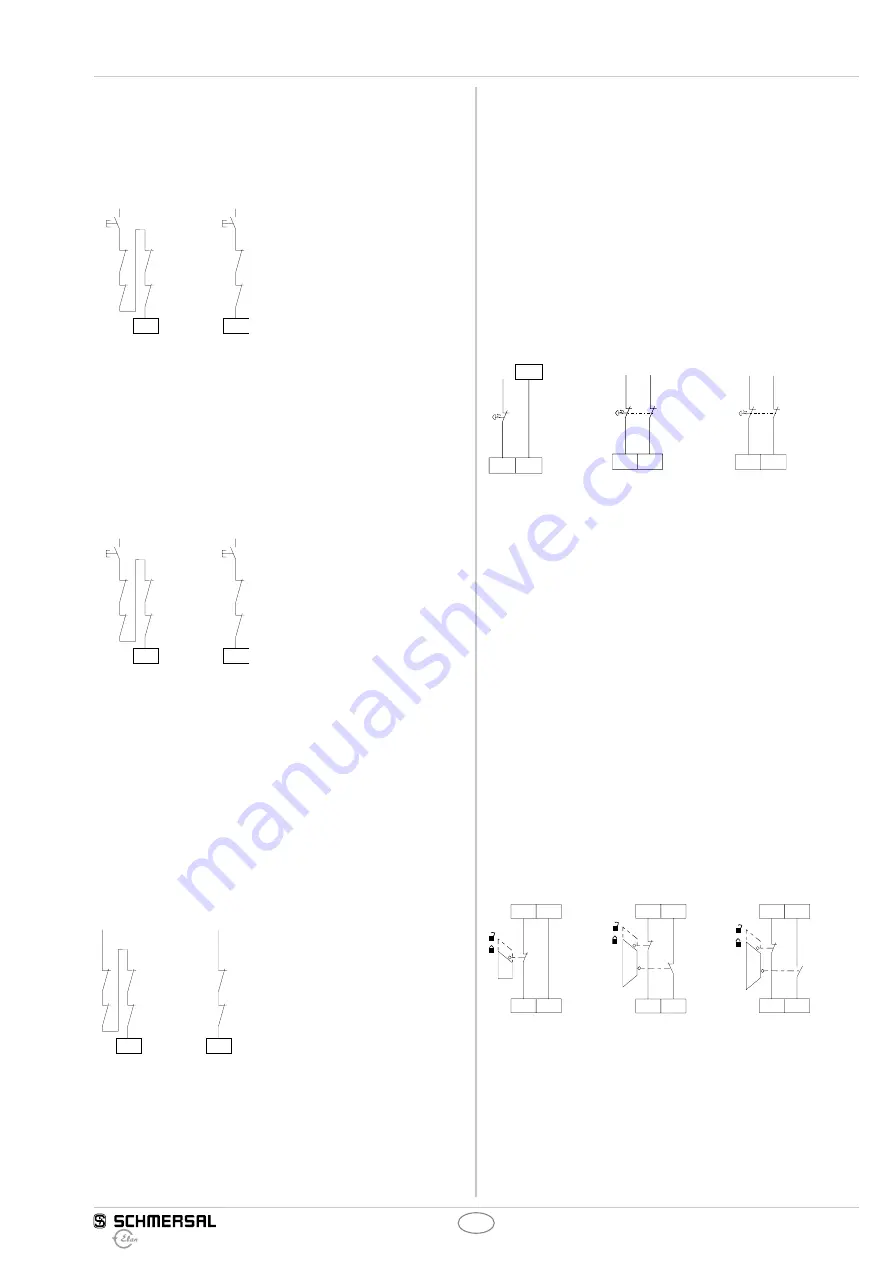

8.2

Start configuration

External reset button (Fig. 5)

•

The external reset button is wired to the terminals X1 (without edge

detection for switch-off level 1) and X2 (without edge detection for

switch-off level 2).

•

The external reset button is integrated in the feedback circuit in series.

K

A

K

B

24 VDC

J

J

X2

24 VDC

K

C

K

D

K

C

K

D

X1

Fig. 5

left = switch-off level 1

right = switch-off level 2 (SRB 202CA, SRB 202CS and SRB 202CA/Q)

External reset button (Fig. 6)

•

The external reset button is wired to the terminals X1 (with edge

detection for switch-off level 1) and X2 (without edge detection for

switch-off level 2).

•

The external reset button is integrated in the feedback circuit in series.

* Automatic start at switch-off level 2: the reset button

J

must be

replaced with a bridge.

K

A

K

B

24 VDC

J

J

X2

*

24 VDC

K

C

K

D

K

C

K

D

X1

Fig. 6

left = switch-off level 1

right = switch-off level 2 (SRB 202CA/T, SRB 202CS/T and SRB 202CA/QT)

Automatic start (see Fig. 7)

•

The automatic start is programmed by connecting the feedback

circuit to the terminals X1 (referring to the switch-off level 1) and X2

(referring to the switch-off level 2). Feedback circuits are not required

to be replaced by a bridge.

•

When the safety-monitoring module is used with the operating mode

“Automatic start”, an automatic restart after a shutdown in case of

emergency must be prevented by the upstream control to EN 60204-1

paragraph 9.2.5.4.2 and 10.8.3.

* An external reset button for a manual start can be installed in

switch-off level 2.

K

A

K

B

24 VDC

X2

*

24 VDC

K

C

K

D

K

C

K

D

X1

Fig. 7

left = switch-off level 1

right = switch-off level 2 (SRB 202CA, SRB 202CS and SRB 202CA/Q)

8.3

Sensor configuration

8.3.1 Sensor configuration superordinated switch-off level 1

Single-channel emergency stop circuit with command devices

to DIN EN ISO 13850 (EN 418) and EN 60947-5-5 (Fig. 8)

•

Wire breakage and earth leakage in the control circuits are detected.

Dual-channel emergency stop circuit with command devices

to DIN EN ISO 13850 (EN 418) and EN 60947-5-5 (Fig. 9)

•

Wire breakage and earth leakage in the control circuits are detected.

•

Cross-wire shorts between the control circuits

are not detected.

Dual-channel emergency stop circuit with command devices

to DIN EN ISO 13850 (EN 418) and EN 60947-5-5 (Fig. 10)

•

Wire breakage and earth leakage in the control circuits are detected.

•

Cross-wire shorts between the control circuits are detected.

S12

S22

S12

24 VDC

S12

S22

24 VDC

24 VDC

S12

S22

24 VDC

0 VDC

Fig. 8

SRB 202CA,

SRB 202CS,

SRB 202CA/T,

SRB 202CS/T

Fig. 9

SRB 202CA,

SRB 202CS,

SRB 202CA/T,

SRB 202CS/T

Fig. 10

SRB 202CA/Q,

SRB202CA/QT

8.3.2 Sensor configuration, partially functioning switch-off level 2

Single-channel guard door monitoring circuit with interlocking

devices to EN 1088 (Fig. 11)

•

With one positive-break position switch.

•

Wire breakage and earth leakage in the control circuits are detected.

Dual-channel guard door monitoring circuit with interlocking

device to EN 1088 (Fig. 12)

•

With at least one positive-break position switch

•

The control system recognises wire-breakage and earth faults in

the control circuit.

•

Cross-wire shorts between the control circuits

are not detected.

Dual-channel guard door monitoring circuit with interlocking

device to EN 1088 (Fig. 13)

•

With at least one positive-break position switch

•

The control system recognises wire-breakage and earth faults in

the control circuit.

•

Cross-wire shorts between the control circuits are detected.

S32

S31

S42

S32

S32

S31

S42

S41

S32

S31

S44

S43

Fig. 11

SRB 202CS,

SRB 202CS/T

Fig. 12

SRB 202CS,

SRB 202CS/T

Fig. 13

SRB 202CA,

SRB 202CA/T,

SRB 202CA/Q,

SRB 202CA/QT