6

Operating instructions

Safety-monitoring module

SRB 202CS / SRB 202CS/T / SRB 202CA/T /

SRB 202CA/QT / SRB 202CA / SRB 202CA/Q

EN

8.3.3 Sensor configuration

Dual-channel control of magnetic safety switches to EN 60947-5-3

(see Fig. 14)

• The control system recognises wire-breakage, earth faults and

cross-wire shorts in the control circuits.

S32

S31

S44

S43

Fig. 14

SRB 202CA, SRB 202CA/T, SRB 202CA/Q, SRB 202CA/QT

The connection of magnetic safety switches to the

SRB 202C.. safety-monitoring modules is only admitted

when the requirements of the standard EN 60 947-5-3

are observed.

As the technical data are regarded, at least the following

requirements must be met:

• Switching capacity: min. 3 W

• Switching voltage: min. 30 VDC

• Switching current: min. 10 mA

For example, the following safety sensors from Schmersal

meet the requirements:

• BNS 33-11z, BNS 33-12z-2063, BNS 33-11z-2063

• BNS 250-11z

• BNS 120-11z

• BNS 180-11z

• BNS 303-11z

Caution!

When sensors with LED are wired in the control

circuit (protective circuit), the following rated operating voltage

must be observed and respected:

– 24 VDC with a max. tolerance of –5 %/+ 20 %

Otherwise availability problems could occur, especially in

series-wired sensors, where a voltage drop in the control

circuit is triggered by LED's for instance.

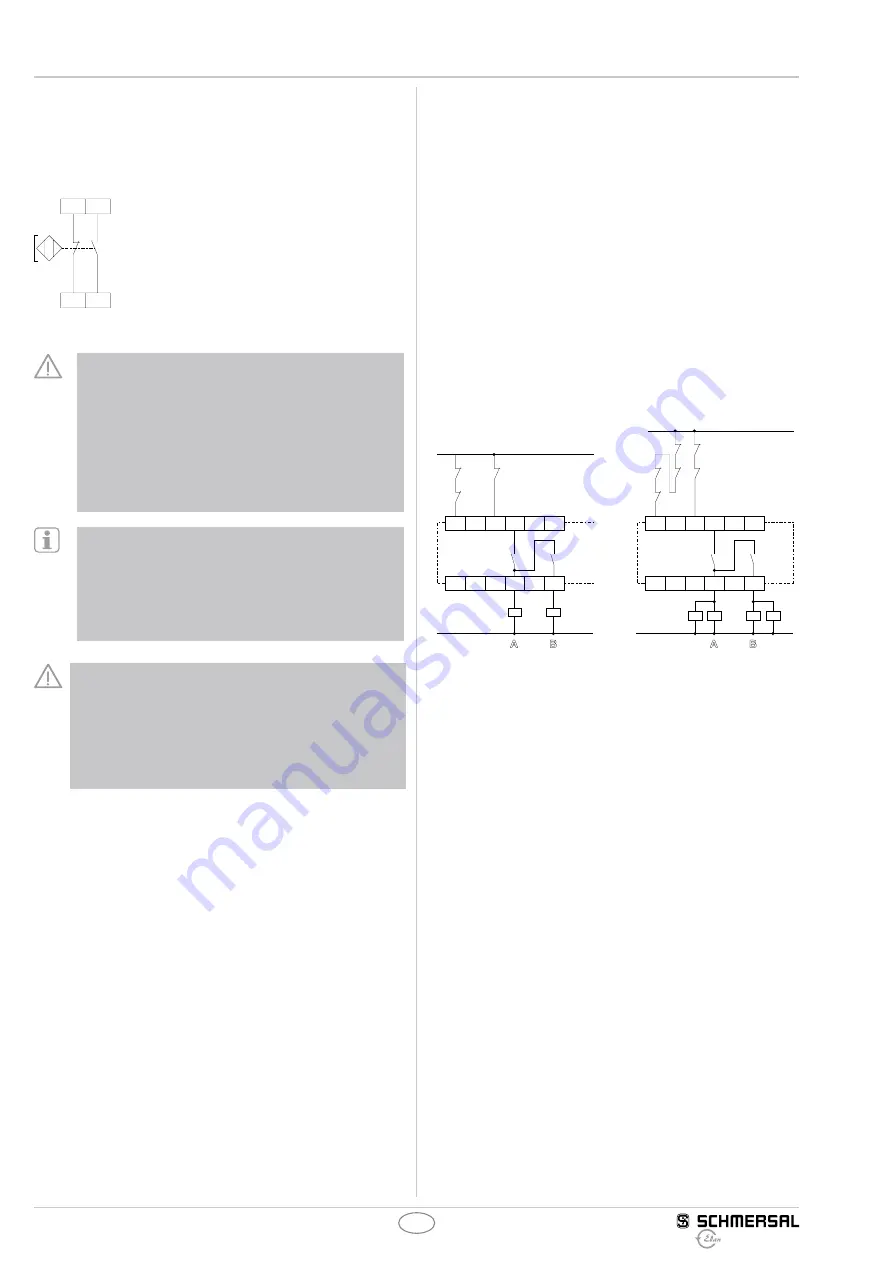

8.4

Actuator configuration

Single-channel control (see Fig. 15)

•

Suitable for increase in capacity or number of contacts by means of

contactors or relays with positive-guided contacts.

•

S

= Feedback circuit:

if the feedback circuit is not required, establish a bridge.

• A = switch-off level 1, B = switch-off level 2

* Disabling of the enabling circuits 13-14, 13-24 when switch-off level 1

is triggered, disabling of the enabling circuit 13-24 when switch-off

level 2 is triggered

Dual-channel control (Fig. 16)

•

Suitable for increase in capacity or number of contacts by means of

contactors or relays with positive-guided contacts.

•

S

= Feedback circuit:

if the feedback circuit is not required, establish a bridge.

• A = switch-off level 1, B = switch-off level 2

* Disabling of the enabling circuits 13-14, 13-24 when switch-off level

1 is triggered, disabling of the enabling circuit 13-24 when switch-off

level 2 is triggered

X1

X2 13

14

L1

N

K

A

K

A

K

B

24

K

B

K

B

*

*

J

J

X1

X2 13

14

24 VDC

N

K

A

K

B

K

C

K

D

K

C

K

D

24

*

K

A

K

B

K

C

K

D

*

J

J J

Fig. 15

Fig. 16