4

Operating instructions

Safety-monitoring module

SRB 202MSK /

SRB 202MSK/QS

EN

6 Set-up and maintenance

6.1 Functional testing

The safety function of the safety-monitoring module must be tested.

The following conditions must be previously checked and met:

1. Correct ixing

2. Check the integrity of the cable entry and connections

3. Check the safety-monitoring module’s enclosure for damage.

4. Check the electrical function of the connected sensors and

their inluence on the safety-monitoring module and the

downstream actuators

6.2 Maintenance

A regular visual inspection and functional test, including the following

steps, is recommended:

1. Check the correct ixing of the safety-monitoring module

2. Check the cable for damages

3. Check electrical function

Damaged or defective components must be replaced.

7 Disassembly and disposal

7.1 Disassembly

The safety-monitoring module must be disassembled in a de-energised

condition only.

7.2 Disposal

The safety-monitoring module must be disposed of in an appropriate

manner in accordance with the national prescriptions and legislations.

5.3 Set-up instructions

The signalling output L84 is used to signal a defective muting lamp.

To set this signalling output, the following steps must be executed:

• Prior to switching the supply voltage (24 VDC) on, check the proper

connection of the SRB 202MSK / SRB 202MSK/QS and connect a

muting lamp to the outputs LA1 and LA2 (min. 100 mA, max. 500 mA).

•

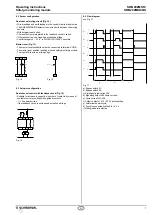

The enclosure must be opened to set the signalling output L84. To open

the front cover, insert a slot screwdriver in the top and bottom cover

notch and gently lift it (Fig. 3 and 4). When the front cover is open, the

electrostatic discharge requirements must be respected and observed.

After the setting, the front cover must be itted back in position.

•

Bring the SRB 202MSK / SRB 202MSK/QS in muting condition

(actuate the sensors S1 and S2 within the timeframe).

•

Check if the muting lamp is on.

•

Connect a voltmeter to output L84 and the 0V potential and turn

the lamp trimmer R1 (Fig. 5) until the signal condition of output L84

changes from 24V to 0V.

•

Remove the muting lamp at the outputs LA1 and LA2. The signal

condition of output L84 changes to 24 V. Reconnect the muting lamp.

•

The set lamp current must be entered on the front cover.

U

B

U

i

K1

K2

K3

K4

K5

LA

A1 X1 X2 MR

S11 S12 S13

S22

S21

S23

X23 L84 X13

24

LA1 13 23 L54

LA2 14

A2

SRB 202MSK

L84: ……. A

U

B

U

i

K1

K2

K3

K4

K5

LA

A1 X1 X2 MR

S11 S12 S13

S22

S21

S23

X23 L84 X13

24

LA1 13 23 L54

LA2 14

A2

SRB 202MSK

L84: ……

…

… . A

U

B

U

i

K1

K2

K3

LA

A1 X1 X2 MR

S11 S12 S13

S22

S21

S23

X23 L84 X13

24

LA1 13 23 L54

LA2 14

A2

SRB 202MSK/QS

L84: ……. A

U

B

U

i

K1

K2

K3

LA

A1 X1 X2 MR

S11 S12 S13

S22

S21

S23

X23 L84 X13

24

LA1 13 23 L54

LA2 14

A2

SRB 202MSK/QS

L84: ……

…

… . A

Fig. 3: SRB 202MSK

Fig. 4: SRB 202MSK/QS

R1

Fig. 5