4

Operating instructions

Safety-monitoring module

SRB 202MSL

EN

5.3 Set-up instructions

According to DIN EN 61496-1 (paragraph A.7.2.2), a failure of the

signal light must cause a bridged condition to be avoided. The

signalling output L84 is used to avoid that the immediate activation of

the emergency stop function of the SRB 202MSL in case of failure of

only one of both muting lamps, so that the operator has the opportunity

to exchange the defective lamp in due time. This function increases

the availability of the system and prevents the shutdown of a relatively

expensive plant due to a simple lamp failure. To set this signalling

output, the following steps must be executed:

• Prior to switching the supply voltage (24 VDC) on, check the proper

connection of the SRB 202MSL and connect a muting lamp to the

outputs LA1 and LA2 (min. 150 mA, max. 500 mA).

• The enclosure must be opened to set the signalling output L84. To

open the front cover, insert a slotted screwdriver in the top and bottom

cover notch and gently lift it (Fig. 2). When the front cover is open, the

electrostatic discharge requirements must be respected and observed.

After setting, the front cover must be fitted back in position.

• Bring the SRB 202MSL in muting condition (actuate the sensors S1

and S2 within the timeframe).

• Check if the muting lamp is on.

• Connect a voltmeter to output L84 and the 0V potential and turn

the lamp trimmer R1 (Fig. 3) until the signal condition of output L84

changes from 0V to 24V.

• Remove the muting lamp at the outputs LA1 and LA2. The signal

condition of output L84 changes to 0V. Reconnect the muting lamp.

• The set lamp current must be entered on the front cover.

U

B

U

i

K1

K2

K3

K4

K5

LA

A1 X1 X2 MR

S11 S12 S13

S22

S21

S23

X23 L84 X13

24

LA1 13 23 L54

LA2 14

A2

SRB 202MSL

L84: 0,24 A

U

B

U

i

K1

K2

K3

K4

K5

LA

A1 X1 X2 MR

S11 S12 S13

S22

S21

S23

X23 L84 X13

24

LA1 13 23 L54

LA2 14

A2

SRB 202MSL

L84: 0,24 A

R1

Fig. 2

Fig. 3

6. Set-up and maintenance

6.1 Functional testing

The safety function of the safety-monitoring module must be tested.

The following conditions must be previously checked and met:

1. Correct fixing

2. Check the integrity of the cable entry and connections

3. Check the safety-monitoring module's enclosure for damage.

4. Check the electrical function of the connected sensors and their

influence on the safety-monitoring module and the downstream

actuators

6.2 Maintenance

A regular visual inspection and functional test, including the following

steps, is recommended:

1. Check the correct fixing of the safety-monitoring module

2. Check the cable for damages

3. Check electrical function

Damaged or defective components must be replaced.

7. Disassembly and disposal

7.1 Disassembly

The safety-monitoring module must be disassembled in a de-energised

condition only.

7.2 Disposal

The safety-monitoring module must be disposed of in an appropriate

manner in accordance with the national prescriptions and legislations.

8. Appendix

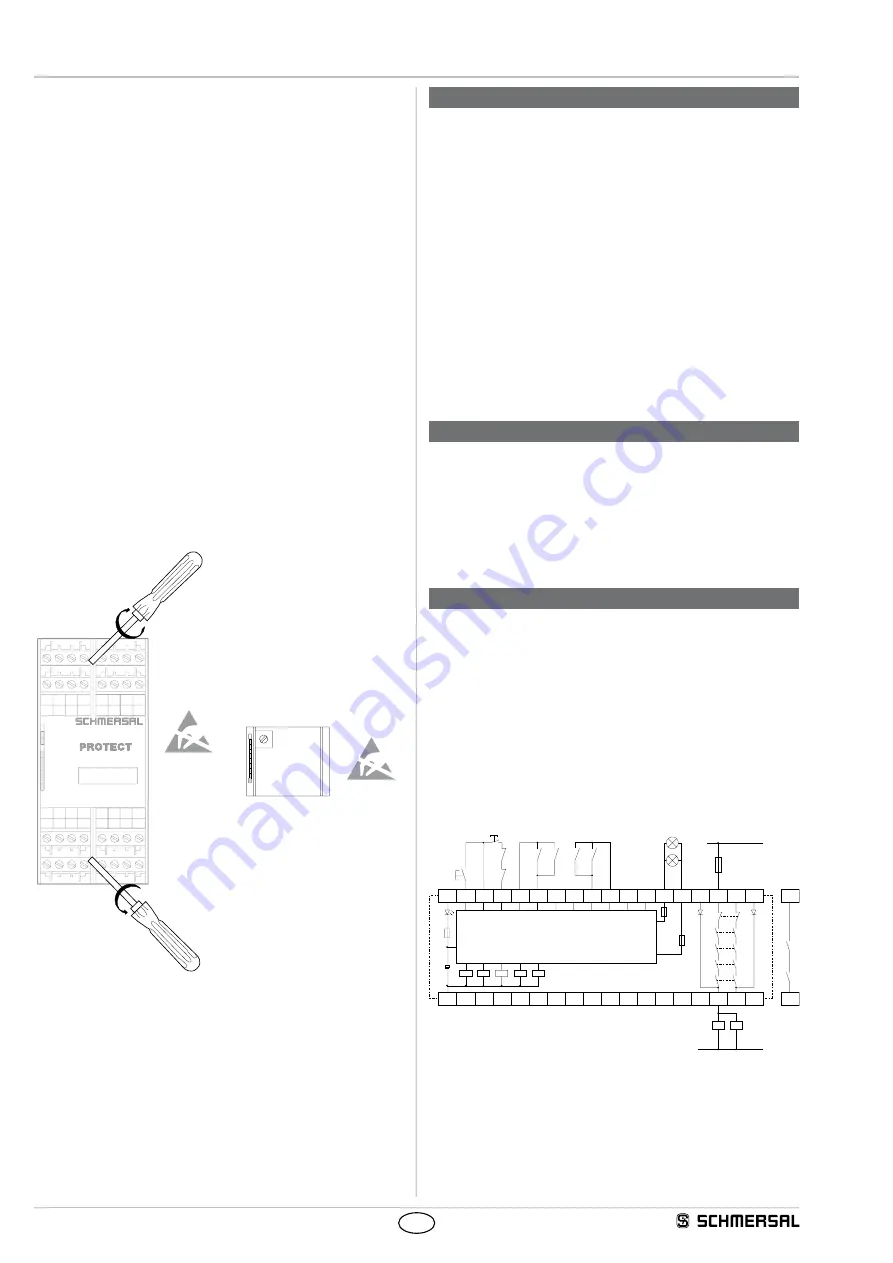

8.1 Wiring examples

Dual-channel control, shown for 2 muting sensors and an external

master reset button

J

(Fig. 4)

• Relay outputs: Suitable for 2-channel control, for increase in capacity

or number of contacts by means of contactors or relays with positive-

guided contacts.

• The control system recognises wire-breakage and earth faults in the

monitoring circuit.

• Cross-wire shorts between the monitoring circuits are detected.

• Electronic fuse F1: 1.25 A

•

S

= Feedback circuit

K4

K1

K2

K3

F1

A1

L

N

K

A

K

A

K1

K2

K3

K4

K5

K

A

K

B

S1

S

J

S2

S4

S3

A2

L54 LA1 LA2 X13

14

13

24

23

X23

a)

Master-

J

S11

+

–

+

–

S12 S13 S21 S22 S23 L84

MR

X1

X2

K

B

K5

K

B

F3

F2

Fig. 4:

b) Logic and lamp monitoring