2

Operating instructions

Safety-monitoring module

SRB 304ST

EN

The entire concept of the control system, in which the safety

component is integrated, must be validated to EN ISO 13849-2.

There are no residual risks, provided that the safety instructions as well

as the instructions regarding mounting, commissioning, operation and

maintenance are observed.

1.6 Warning about misuse

In case of inadequate or improper use or manipulations of

the safety-monitoring module, personal hazards or damage

to machinery or plant components cannot be excluded.

The relevant requirements of the standards ISO 14119 and

EN ISO 13850 must be observed.

1.7 Exclusion of liability

We shall accept no liability for damages and malfunctions resulting from

defective mounting or failure to comply with this operating instructions

manual. The manufacturer shall accept no liability for damages

resulting from the use of unauthorised spare parts or accessories.

For safety reasons, invasive work on the device as well as arbitrary

repairs, conversions and modifications to the device are strictly

forbidden; the manufacturer shall accept no liability for damages

resulting from such invasive work, arbitrary repairs, conversions and/or

modifications to the device.

The safety-monitoring module must only be used when the enclosure is

closed, i.e. with the front cover fitted.

2. Product description

2.1 Ordering code

This operating instructions manual applies to the following types:

SRB 304ST

Only if the information described in this operating instructions

manual are realised correctly, the safety function and therefore

the compliance with the Machinery Directive is maintained.

2.2 Special versions

For special versions, which are not listed in the order code below 2.1,

these specifications apply accordingly, provided that they correspond to

the standard version.

2.3 Destination and use

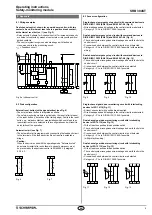

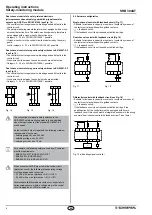

The safety-monitoring modules for integration in safety circuits are

designed for fitting in control cabinets. They are used for the safe

evaluation of the signals of positive break position switches for safety

functions or magnetic safety sensors on sliding, hinged and removable

safety guards as well as emergency stop control devices and AOPD's

(safety light barriers).

The safety function is defined as the opening of enabling circuits 13-14,

23-24 and 33-34 when the inputs S11-S12 and/or S21-S22 and/or

S31-S32 are opened. The safety-relevant current paths with the output

contacts 13-14, 23-24 and 33-34 meet the following requirements

under observation of a PFH value assessment (also refer to chapter 2.5

"Safety classification"):

– Control category 4 – PL e to DIN EN ISO 13849-1

– Corresponds to SIL 3 to DIN EN 61508-2

– SILCL 3 to DIN EN 62061

To determine the Performance Level (PL) of the entire safety function

(e.g. sensor, logic, actuator) to DIN EN ISO 13849-1, an analysis of all

relevant components is required.

2.4 Technical data

General data:

Standards:

IEC/EN 60204-1, EN 60947-5-1,

EN ISO 13849-1, IEC/EN 61508

Climate resistance:

EN 60068-2-78

Mounting:

Snaps onto standard DIN rail to EN 60715

Terminal designations:

EN 60947-1

Material of the housings:

Plastic, glass-fibre reinforced thermoplastic,

ventilated

Material of the contacts:

AgSnO, self-cleaning, positive drive

Weight:

340 g

Start conditions:

Automatic or start button (monitored)

Feedback circuit available:

yes

Pull-in delay for automatic start:

typ. 250 ms

Pull-in delay with reset button:

typ. 20 ms

Drop-out delay in case of emergency stop:

typ. 30 ms / max. 36 ms

Drop-out delay on "supply failure":

typ. 80 ms

Mechanical data:

Connection type:

Screw connection

Cable sections:

0.25 … 2.5 mm²

Connecting cable:

rigid or flexible

Tightening torque for the terminals:

0.6 Nm

With removable terminals:

yes

Mechanical life:

10 million operations

Resistance to shock:

10 g / 11 ms

Resistance to vibrations to EN 60068-2-6:

10 … 55 Hz,

amplitude 0.35 mm

Ambient temperature:

– 25 °C … +60 °C

Storage and transport temperature:

–40 °C … +85 °C

Protection class:

Enclosure: IP40

Terminals:

IP20

Clearance: IP54

Air clearances and creepage

distances to IEC/EN 60664-1:

4 kV/2 (basic insulation)

EMC rating:

to EMC Directive

Electrical data:

Contact resistance in new state:

max. 100 mΩ

Power consumption:

max. 1.9 W / 4.9 VA,

plus signalling outputs

Rated operating voltage U

e

:

24 VDC: –15% / +20%,

residual ripple max. 10%,

24 VAC: –15% / +10%

Frequency range:

50 / 60 Hz

Fuse rating for the operating voltage:

Internal electronic trip,

tripping current F1: > 2.5 A;

tripping current F2: > 50 mA (S11-S31) / > 800 mA (X4)

Current and voltage at the control circuits:

- S11, S12, S21, S22, S31, S32:

24 VDC, 10 mA

- X1, X2:

24 VDC, start impulse 350 mA / 15 ms

- X3, X4:

24 VDC, start impulse 130 mA / 80 ms

- X4, X5:

24 VDC, start impulse 140 mA / 15 ms

Monitored inputs:

Cross-wire detection:

optional

Wire breakage detection:

yes

Earth connection detection:

yes

Number of NO contacts:

0

Number of NC contacts:

2

Cable length:

850 m with 1.5 mm²,

1,400 m with 2.5 mm²

Conduction resistance:

max. 10 Ω