4

Operating instructions

Safety-monitoring module

SRB 304ST

EN

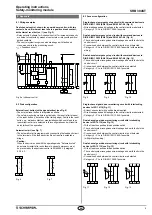

Opening the front cover (see Fig. 2)

• To open the front cover, insert a slotted screwdriver in the top and

bottom cover notch and gently lift it.

• When the front cover is open, the electrostatic discharge requirements

must be respected and observed.

• After setting, the front cover must be fitted back in position.

Only touch the components after electrical discharge!

U

B

U

i

K1

K2

13 23 33 41

A2 S21 A1.1 S22

14 24 34 42

Y1

A1 S11 S12 X5

X3

X1

X2

Y2

X4

S32

S31

Y3

SRB 304ST

U

B

U

i

K1

K2

13 23 33 41

A2 S21 A1.1 S22

14 24 34 42

Y1

A1 S11 S12 X5 X3

X1

X2

Y2

X4

S32

S31

Y3

SRB 304ST

Fig. 1

Fig. 2

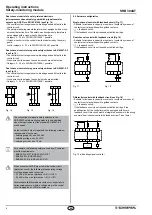

Resetting the hybrid fuse

• The hybrid fuse of the safety-monitoring module can be reset

by switching the operating voltage off and back on or by actuating

button S1.

• Button S1 is located underneath the front cover of the safety-

monitoring module (see Fig. 2 and 3).

S1

Fig. 3

5.3 Notes

Signalling outputs (see fig. 4)

• The input circuits are signalled through the signalling outputs Y1

(channel 1) and Y2 (channel 2).

• The status of the hybrid fuse is signalled through signalling output

Y3. If the hybrid fuse is not activated, Y3 is supplied with operating

voltage.

+24 V

F2

Y3

Y2

Y1

Fig. 4

6. Set-up and maintenance

6.1 Functional testing

The safety function of the safety-monitoring module must be tested.

The following conditions must be previously checked and met:

1. Correct fixing

2. Check the integrity of the cable entry and connections

3. Check the safety-monitoring module's enclosure for damage.

4. Check the electrical function of the connected sensors and their

influence on the safety-monitoring module and the downstream

actuators

6.2 Maintenance

A regular visual inspection and functional test, including the following

steps, is recommended:

1. Check the correct fixing of the safety-monitoring module

2. Check the cable for damages

3. Check electrical function

The device has to be integrated into the periodic check-ups

according to the Ordinance on Industrial Safety and Health,

however at least 1 × year.

Damaged or defective components must be replaced.

7. Disassembly and disposal

7.1 Disassembly

The safety-monitoring module must be disassembled in a de-energised

condition only.

Push up the bottom of the enclosure and hang out slightly tilted

forwards.

7.2 Disposal

The safety-monitoring module must be disposed of in an appropriate

manner in accordance with the national prescriptions and legislations.