5

SRB 304ST

Operating instructions

Safety-monitoring module

EN

8. Appendix

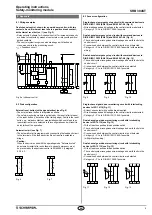

8.1 Wiring examples

Dual-channel control, shown for a guard door monitor; with two

contacts A and B, where at least one is a positive break contact;

with external reset button

J

(see Fig. 5)

• Relay outputs: Suitable for 2-channel control, for increase in capacity

or number of contacts by means of contactors or relays with positive-

guided contacts.

• The control system recognises wire breakage, earth faults and

cross-wire shorts in the monitoring circuit.

•

S

= Feedback circuit

A1 A1.1 S21 S22 S11 X5

J

X3 X4 S12 X1 X2 S32 S31

A2

Y3 Y2 Y1

S

K2

K2

a)

K1

K1

F2

F1

13

23 33

L1

K2

K1

K

A

K

B

K

B

K

A

K2

K1

41

14 24 34 42

Fig. 5 a) channel control

8.2 Start configuration

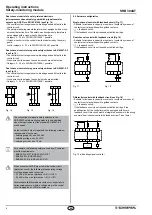

External reset button (with edge detection) (see Fig. 6)

• The external reset button is integrated as shown.

• The safety-monitoring module is activated by the reset (after release)

of the reset button (= detection of the trailing edge). Faults in the reset

button, e.g. welded contacts or manipulations which could lead to an

inadvertent restart, are detected in this configuration and will result in

an inhibition of the operation.

Automatic start (see Fig. 7)

• The automatic start is programmed by connecting the feedback circuit

to the terminals. If the feedback circuit is not required, establish a

bridge.

•

Caution:

When the device is used with the operating mode "Automatic start",

an automatic restart after a shutdown in case of emergency must

be prevented by the upstream control to EN 60204-1, paragraph

9.2.5.4.2.

X2

S

X1

X4

X3

K

A

K

B

X2

S

X1

X4

X5

K

A

K

B

Fig. 6

Fig. 7

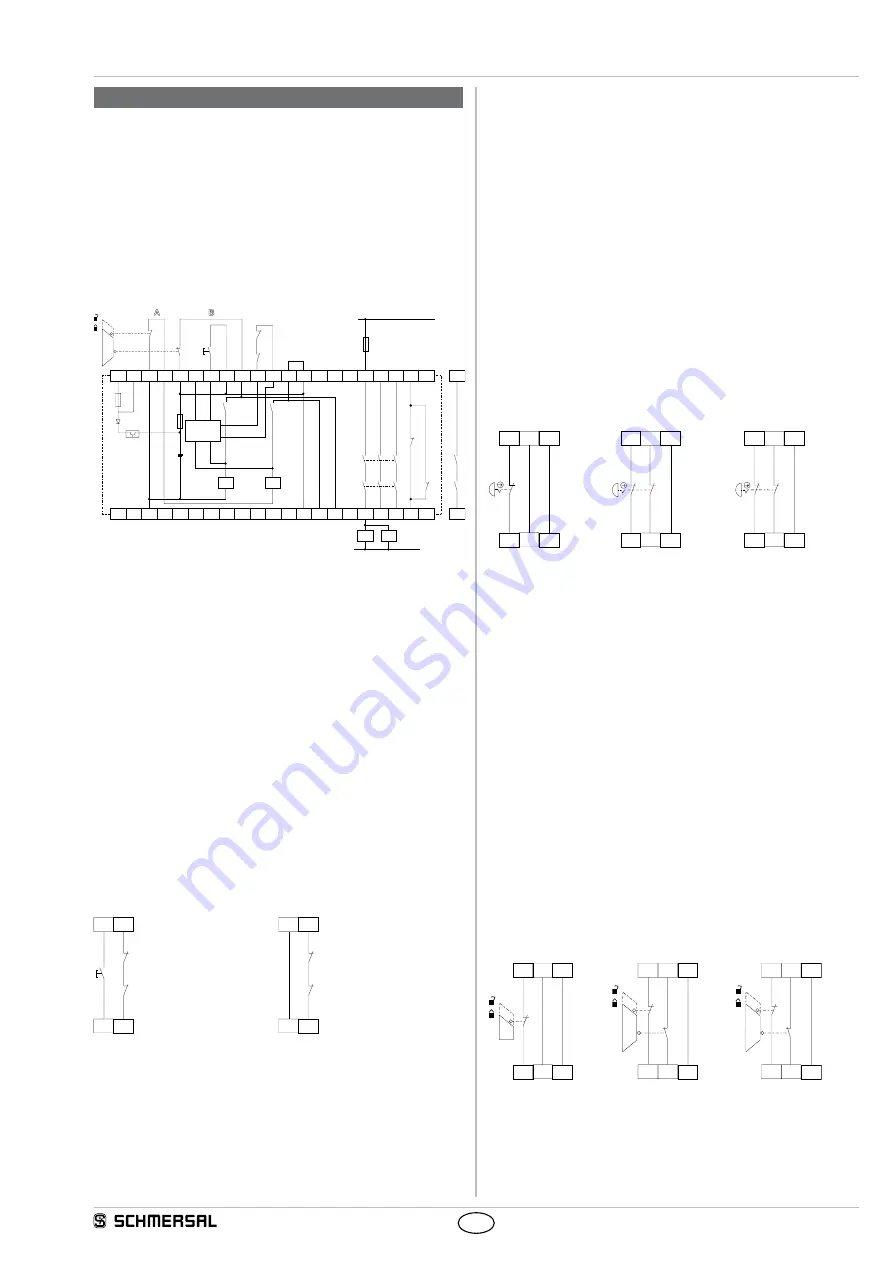

8.3 Sensor configuration

Single-channel emergency stop circuit with command devices to

DIN EN ISO 13850 (EN 418) and EN 60947-5-5 (Fig. 8)

• Wire breakage and earth leakage in the control circuits are detected.

• Category 2 – PL d to DIN EN 13849-1 possible

Dual-channel emergency stop circuit with command devices to

DIN EN ISO 13850 (EN 418) and EN 60947-5-5 (Fig. 9)

• The control system recognises wire-breakage and earth faults in the

control circuit.

• Cross-wire shorts between the control circuits are not detected.

• Category 4 – PL e to DIN EN ISO 13849-1 possible (with protective

wiring)

Dual-channel emergency stop circuit with command devices to

DIN EN ISO 13850 (EN 418) and EN 60947-5-5 (Fig. 10)

• The control system recognises wire-breakage and earth faults in the

control circuit.

• Cross-wire shorts between the control circuits are detected.

• Category 4 – PL e to DIN EN ISO 13849-1 possible.

S12

S11

S32

S12

S22

S21

S12

S11

S32

S31

S22

S21

S12

S11

S22

S21

S32

S31

Fig. 8

Fig. 9

Fig. 10

Single-channel guard door monitoring circuit with interlocking

devices to ISO 14119 (Fig. 11)

• At least one contact with positive break required.

• Wire breakage and earth leakage in the control circuits are detected.

• Category 2 – PL d to DIN EN ISO 13849-1 possible.

Dual-channel guard door monitoring circuit with interlocking

device to ISO 14119 (see Fig. 12)

• With at least one positive-break position switch

• The control system recognises wire-breakage and earth faults in the

control circuit.

• Cross-wire shorts between the control circuits are not detected.

• Category 4 – PL e to DIN EN ISO 13849-1 possible

(with protective wiring)

Dual-channel guard door monitoring circuit with interlocking

device to ISO 14119 (see Fig. 13)

• With at least one positive-break position switch

• The control system recognises wire-breakage and earth faults in the

control circuit.

• Cross-wire shorts between the control circuits are detected.

• Category 4 – PL e to DIN EN 13849-1 possible

S12

S11

S32

S12

S22

S21

S12

S11

S32

S31

S22

S21

S12

S11

S22

S21

S32

S31

Fig. 11

Fig. 12

Fig. 13