4

Operating instructions

Safety-monitoring module

SRB 308IT

EN

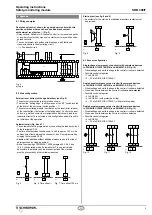

Setting the switch (see Fig. 3)

•

The "automatic start" or "trailing edge" function is programmed

by means of the switch underneath the front cover of the safety-

monitoring module.

•

The switch must only be operated in de-energised condition by

means of a inger or an insulated blunt tool.

• Pos. AF = 1 (LHS, condition on delivery): the external reset button

is monitored for a "trailing edge".

• Pos. AF = 0 (RHS): "automatic start" programmed

Only touch the components after electrical discharge!

AF

1

0

Fig. 3

Condition on delivery AF = 1

6 Set-up and maintenance

6.1 Functional testing

The safety function of the safety-monitoring module must be tested.

The following conditions must be previously checked and met:

1. Correct ixing

2. Check the integrity of the cable entry and connections

3. Check the safety-monitoring module's enclosure for damage.

4. Check the electrical function of the connected sensors and

their inluence on the safety-monitoring module and the

downstream actuators

6.2 Maintenance

A regular visual inspection and functional test, including the following

steps, is recommended:

1. Check the correct ixing of the safety-monitoring module

2. Check the cable for damages

3. Check electrical function

Damaged or defective components must be replaced.

7 Disassembly and disposal

7.1 Disassembly

The safety-monitoring module must be disassembled in a de-energised

condition only.

7.2 Disposal

The safety-monitoring module must be disposed of in an appropriate

manner in accordance with the national prescriptions and legislations.

5.3 Notes

Indications

Status

A

Module

off

B

Module

off

C

Module

started

D

Module

started

E

Module

on

Y1 – Operating

voltage

1

1

1

1

1

Y2 – Internal

voltage

1

1

1

1

1

Y3 – Channel 1

(S11-S12)

0

1

1

1

1

Y4 – Channel 2

(S21-S22, S31-S32)

0

1

1

1

1

Y5 – Feedback

circuit

1

1

1

1

0

Y6 – Relays K1

0

0

0

1

0

41-42 – Auxiliary

NC contact

1

1

1

1

→

0

0

53-54 - Auxiliary

NO contact

0

0

0

0

→

1

1

•

A: operating voltage is on, safety guard open, feedback circuit closed

•

B: operating voltage is on, safety guard closed, feedback circuit

closed

•

C: operating voltage is on, safety guard closed, feedback circuit

closed, reset button actuated

•

D: operating voltage is on, safety guard closed, feedback circuit

closed, reset button released

•

E: operating voltage is on, safety guard closed, feedback circuit open

Opening the front cover (see Fig. 2)

•

To open the front cover, insert a slot screwdriver in the top and

bottom cover notch and gently lift it.

•

When the front cover is open, the electrostatic discharge requirements

must be respected and observed.

• After the setting, the front cover must be itted back in position.

Only touch the components after electrical discharge!

K3

K2

K1

Ui

UB

S31 S32 X6 X4

S22 S21

S11

X2

53

Y5

13 23 33 X5

X3

41

Y6

A1

Y4

54

Y2

A1.1

S12

14 24

X1

Y3

42

Y1

A2

34

SRB 308IT

K3

K2

K1

Ui

UB

S31 S32 X6 X4

S22 S21

S11

X2

53

Y5

13 23 33 X5

X3

41

Y6

A1

Y4

54

Y2

A1.1

S12

14 24

X1

Y3

42

Y1

A2

34

SRB 308IT

K3

K2

K1

Ui

UB

S31 S32 X6 X4

S22 S21

S11

X2

53

Y5

13 23 33 X5

X3

41

Y6

A1

Y4

54

Y2

A1.1

S12

14 24

X1

Y3

42

Y1

A2

34

SRB 308IT

Fig. 1

Fig. 2