6

Operating instructions

Safety-monitoring module

SRB 308IT

EN

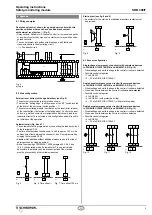

Single-channel guard door monitoring circuit with interlocking

devices to EN 1088 (Fig. 13)

•

At least one contact with positive break required

•

Wire breakage and earth leakage in the control circuits are detected.

•

Possible control categories:

– 1 to EN 954-1

– 2 – PL d to DIN EN ISO 13849-1

Dual-channel guard door monitoring circuit with interlocking

device to EN 1088 (Fig. 14)

•

At least one contact with positive break required

•

Wire breakage and earth leakage in the control circuits are detected.

•

Cross-wire shorts between the monitoring circuits are not detected.

•

Possible control categories:

– 3 to EN 954-1

– 4 to EN 954-1 (with protective wiring)

– 4 – PL e to DIN EN ISO 13849-1 (with protective wiring)

Dual-channel guard door monitoring circuit with interlocking

device to EN 1088 (Fig. 15)

•

At least one contact with positive break required

•

Wire breakage and earth leakage in the control circuits are detected.

•

Cross-wire shorts between the guard monitoring circuits are detected.

•

Possible control categories:

– 4 to EN 954-1

– 4 – PL e to DIN EN ISO 13849-1

S12

Y3

a)

S11

S22

Y4

S12

S32

S31

S12

Y3

a)

S11

S22

Y4

S21

S32

S31

S12

Y3

a)

S11

S22

Y4

S21

S32

S31

Fig. 13

Fig. 14

Fig. 15

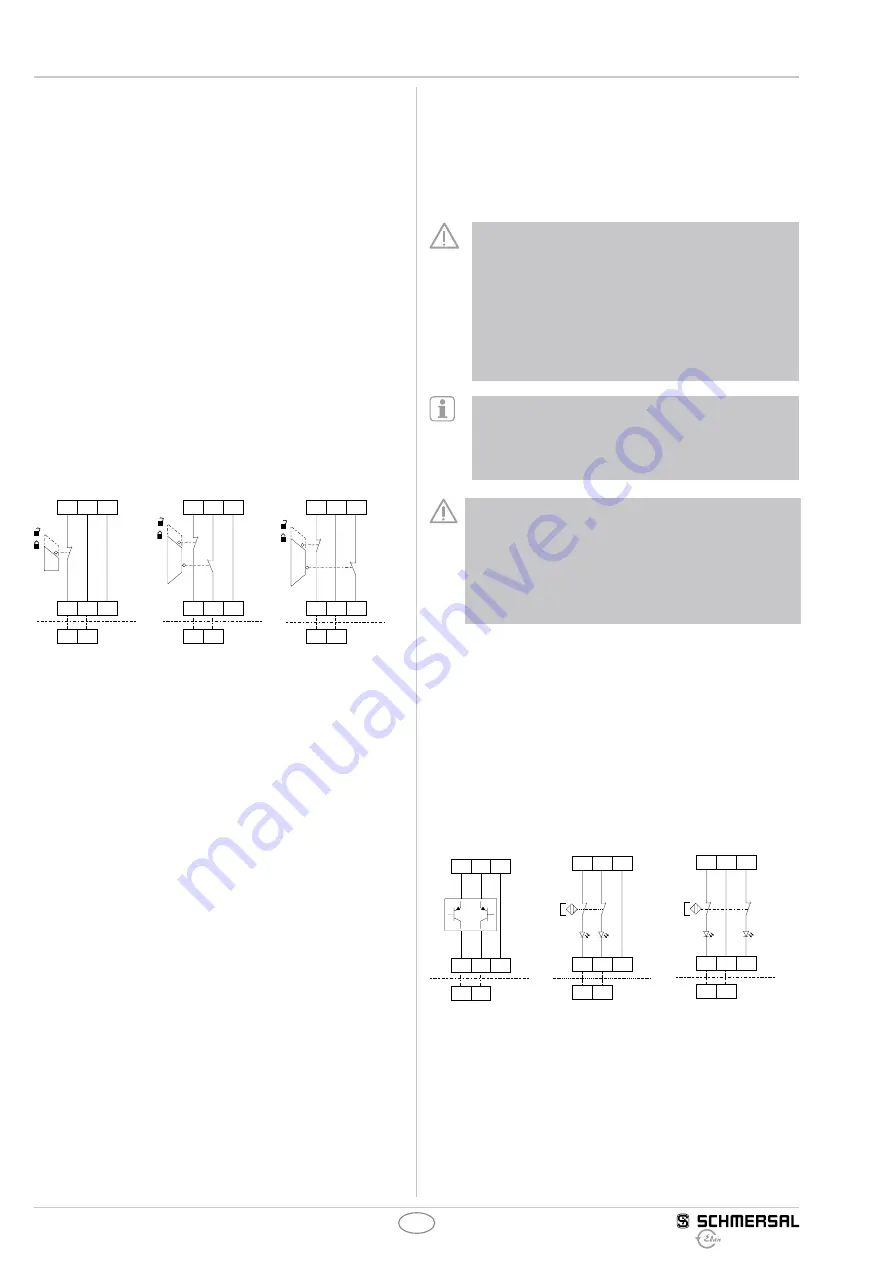

Dual-channel control of a safety-related electronic (micro-

processor-based) safety guard with p-type transistor outputs

e.g. AOPD's to EN IEC 61496 (see Fig. 16)

•

Wire breakage and earth leakage in the control circuits are detected.

•

Cross-wire shorts between the control circuits are usually detected

by the safety guards. The safety-monitoring module therefore is not

equipped with a cross-wire short detection here.

•

Possible control categories:

– If cross-wire shorts in the control circuits are detected

by the safety guard:

– 4 to EN 954-1

– 4 – PL e to DIN EN ISO 13849-1

If cross-wire shorts in the control circuits are detected

by the safety guard.

Dual-channel control of magnetic safety switches according

to EN 60947-5-3 (see Fig. 17)

•

The control system recognises wire-breakage and earth faults in the

control circuit.

•

Cross-wire shorts between the control circuits

are not detected.

•

Possible control categories:

– 3 to EN 954-1

– 3 – PL e to DIN EN ISO 13849-1

2-channel control of magnetic safety switches according

to EN 60947-5-3 (see Fig. 15)

•

The control system recognises wire-breakage and earth faults

in the control circuit.

•

Cross-wire shorts between the control circuits are detected.

•

Possible control categories:

– 3 to EN 954-1

– 3 – PL d to DIN EN ISO 13849-1

The connection of magnetic safety switches to the

SRB 308IT safety-monitoring module is only admitted

when the requirements of the standard EN 60 947-5-3

are observed.

As the technical data are regarded, the following minimum

requirements must be met:

– switching capacity: min. 1.4 mW

– switching voltage: min. 28 VDC

– switching current: min. 50 mA

For example, the following safety sensors meet the

requirements:

– BNS 33-02z-2187

– BNS 260-02z, BNS260-02

– BNS 260-02-01z, BNS260-02-01

Caution!

When sensors with LED are wired in the control

circuit (protective circuit), the following rated operating

voltage must be observed and respected:

– 24 VDC with a max. tolerance of –5 %/+ 20 %

Otherwise availability problems could occur, especially in

series-wired sensors, where a voltage drop in the control

circuit is triggered by LED's for instance.

Dual-channel control of a safety-related electronic (micro-

processor-based) safety guard with p-type transistor outputs

e.g. AOPD's to EN IEC 61 496 (see Fig. 18)

•

Wire breakage and earth leakage in the control circuits are detected.

•

Cross-wire shorts between the control circuits are usually detected

by the safety guards. The safety-monitoring module therefore is not

equipped with a cross-wire short detection here.

•

Control category: 3 to EN 954-1:1997

•

If cross-wire shorts in the control circuits are detected

by the safety guard:

– control category 4 to EN 954-1:1997

– control category 4 – PL e to DIN EN ISO 13 849-1 possible.

S12

Y3

a)

S11

+24V +24V

S22

Y4

S21

S32

S31

S12

Y3

a)

S11

S22

Y4

S12

S32

S31

S12

Y3

a)

S11

S22

Y4

S12

S32

S31

Fig. 16

Fig. 17

Fig. 18