3

SRB 324ST/R V.3

Operating instructions

Safety-monitoring module

EN

Switching capacity of

the safety contacts:

13-14, 23-24, 33-34 (STOP 0):

max. 250 V, 8 A ohmic (inductive in

case of suitable protective wiring);

AC-15: 230 VAC / 6 A,

DC-13: 24 VDC / 6 A;

residual current at ambient temperature

up to 45°C: 18 A / 55°C: 15 A /

60°C: 12 A

57-58, 67-68 (STOP 1):

max. 250 V, 6 A ohmic (inductive in

case of suitable protective wiring);

AC-15: 230 VAC / 3 A,

DC-13: 24 VDC / 2 A;

residual current at ambient temperature

up to 45°C: 12 A / 55°C: 10 A /

60°C: 8 A

Switching capacity of

the signalling outputs:

Z1-Z3: 24 VDC / 100 mA,

residual current: 200 mA

Switching capacity of

the auxiliary contacts:

41-42: 24 VDC / 2 A

Fuse rating of the

safety contacts:

STOP 0: 8 A slow blow

STOP 1: 6.3 A slow blow

Fuse rating of the

signalling outputs:

500 mA

(internal electronic fuse F3)

Recommended fuse for

the auxiliary contacts:

2 A slow blow

Utilisation category

to EN 60947-5-1:

AC-15, DC-13

Dimensions (H/W/D):

100 mm × 45 × 121 mm

The data specified in this manual are applicable when the component

is operated with rated operating voltage U

e

±0%.

2.5 Safety classification

Standards:

EN ISO 13849-1, IEC 61508,

EN 60947-5-1

PL:

Stop 0: up to e

Stop 1: up to d

Control category:

Stop 0: up to 4

Stop 1: up to 3

DC:

Stop 0: 99% (high)

Stop 1: > 60% (low):

CCF:

> 65 points

SIL:

Stop 0: up to 3

Stop 1: up to 2

Service life:

20 years

B

10d

value (for one channel):

20%: 20,000,000

40%: 7,500,000

60%: 2,500,000

80%: 1,000,000

100%: 400,000

MTTF

B

d x

x

h

s/h

3600

d

10d

op

op

op

n

0,1 x n

op

t

cycle

For an average annual demand rate of n

op

= 126,720 cycles per year,

Performance Level PL e can be obtained at maximum load.

n

op

= average number of activations per year

d

op

= average number of operating days per year

h

op

= average number of operating hours per day

t

cycle

= average demand rate of the safety function in s

(e.g. 4 × per hour = 1 × per 15 min. = 900 s)

(Specifications can vary depending on the application-specific

parameters h

op

, d

op

and t

cycle

as well as the load.)

3 Mounting

3.1 General mounting instructions

Mounting: snaps onto standard DIN rails to EN 60715.

Snap the bottom of the enclosure slightly tilted forwards in the

DIN rail and push up until it latches in position.

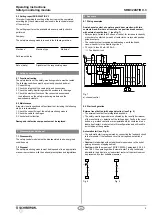

3.2 Dimensions

All measurements in mm.

Device dimensions (H/W/D): 100 x 45 x 121 mm

with plugged-in terminals: 120 × 45 × 121 mm

4 Electrical connection

4.1 General information for electrical connection

The electrical connection may only be carried out by

authorised personnel in de-energised condition.

Wiring examples: see appendix

5 Operating principle and settings

LED functions

•

K1: Status channel 1

•

K2: Status channel 2

•

K3/K4: Status delayed enabling circuit (LED is ON, when the

delayed enabling circuits 47-48, 57-58 are closed)

•

U

B

: Status operating voltage (LED is on, when the operating

voltage on the terminals A1-A2 is ON)

•

Ui: Status internal operating voltage (LED is on, when the

operating voltage on the terminals A1-A2 is ON and the fuse

has not been triggered)

Terminal description (see Fig. 1)

Voltages: A1

A2

+24 VDC / 24 VAC

0 VDC / 24 VAC

Inputs:

S11-S12

S11-S22

S21-S22

S12-B1

S31

Input channel 1 (+)

Input channel 2 (+)

Input channel 2 (–) (with cross-wire short detection)

Input channel 2 (–) (without cross-wire short detection)

+24 VDC

Out-

puts:

13-14

23-24

33-34

57-58

67-68

First safety enabling circuit (stop 0)

Second safety enabling circuit (stop 0)

Third safety enabling circuit (stop 0)

Fourth safety enabling circuit (stop 1)

Fifth safety enabling circuit (stop 1)

Start:

Y2-X5

Y2-S33

Z1 + Z2

Z3

Feedback circuit / Automatic start

Feedback circuit and external reset (monitored)

Signalling output channel 1 and 2

Fuse F3