4

Operating instructions

Safety-monitoring module

SRB 324ST/R V.3

EN

Opening the front cover (see Fig. 2)

•

To open the front cover, insert a slot screwdriver in the top and bottom

cover notch and gently lift it.

•

When the front cover is open, the electrostatic discharge requirements

must be respected and observed.

• After the setting, the front cover must be fitted back in position.

•

The set drop-out delay must be entered on the front cover.

Only touch the components after electrical discharge!

U

B

U

i

K1

K2

K3

K4

13 23 33 41

A1 S11 S12 X5

A2 S21

S22

14 24 34 42

57 67

Z1

B1

Z2

Y2

S33

S31

58 68

Z3

SRB 324ST/R

V.3

t: 1,0 s

U

B

U

i

K1

K2

K3

K4

13 23 33 41

A1 S11 S12 X5

A2 S21

S22

14 24 34 42

57 67

Z1

B1

Z2

Y2

S33

S31

58 68

Z3

SRB 324ST/R

V.3

t: 1,0 s

U

B

U

i

K1

K2

K3

K4

13 23 33 41

A1 S11 S12 X5

A2 S21

S22

14 24 34 42

57 67

Z1

B1

Z2

Y2

S33

S31

58 68

Z3

SRB 324ST/R

V.3

t: 1,0 s

Fig. 1

Fig. 2

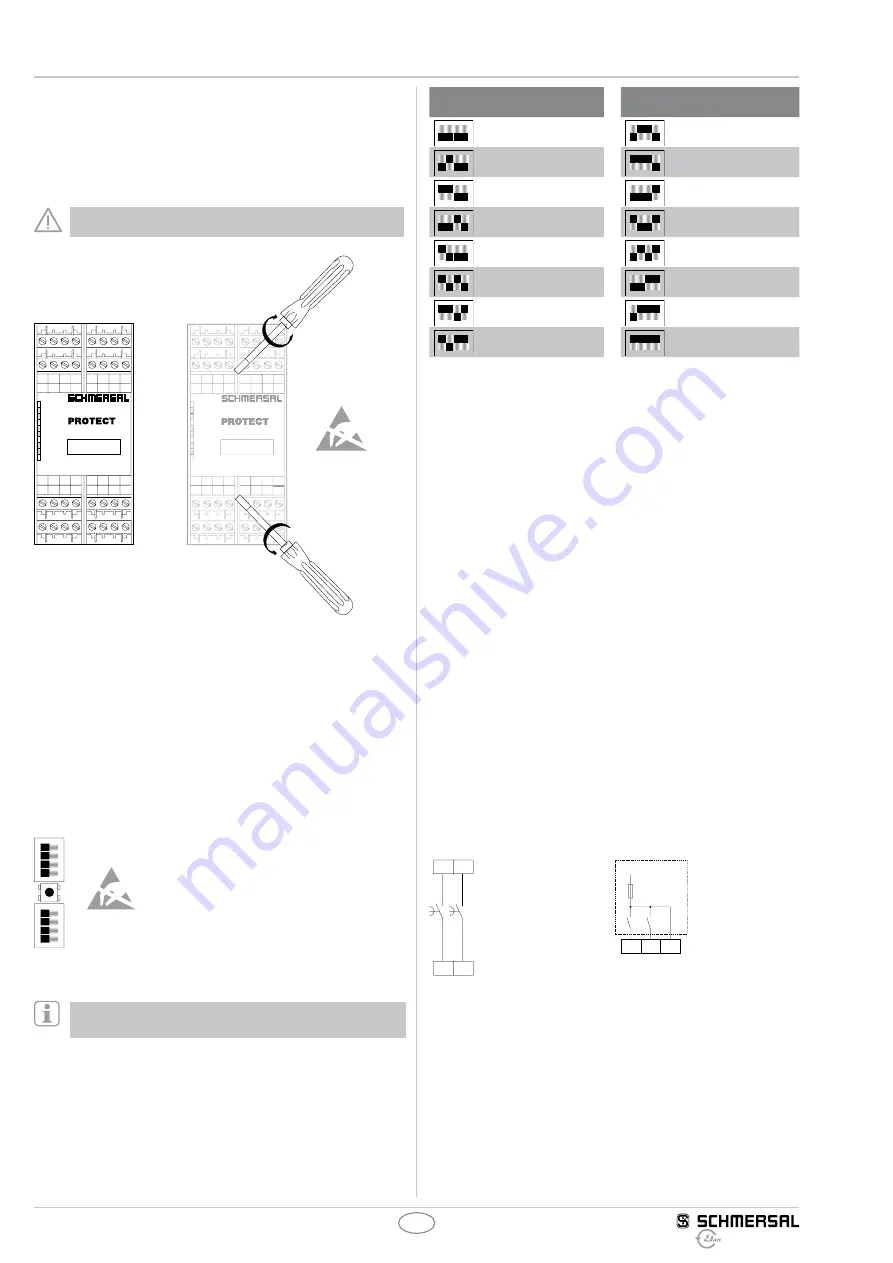

Time setting (see Fig. 3 and 4)

DIP switch settings:

•

The DIP switches are located underneath the front cover of the

safety-monitoring module (see Fig. 3 and 4).

•

Both DIP switches SW 1 (channel 1) and SW 2 (channel 2) must

be set identically.

• The DIP switches can be set when the operating voltage is on;

however, in order for the setting to be saved in the SRB 324ST/R V.3,

the voltage supply must be interrupted for approx. 3 seconds.

•

Factory setting: 1 sec.

ON

ON

SW1

SW2

1

1

2

2

3

3

4

4

S1

Fig. 3

New adjustable drop-out delays and cross-wire short

monitoring for version V.3! See Fig. 4. Tolerance ± 2%

DIP switch

setting

Drop-out

delay

DIP switch

setting

Drop-out

delay

ON

1

2

3

4

<0.1 s

ON

1

2

3

4

5.0 s

ON

1

2

3

4

0.5 s

ON

1

2

3

4

8.5 s

ON

1

2

3

4

1.0 s

ON

1

2

3

4

10.0 s

ON

1

2

3

4

1.5 s

ON

1

2

3

4

12.0 s

ON

1

2

3

4

2.0 s

ON

1

2

3

4

15.0 s

ON

1

2

3

4

2.5 s

ON

1

2

3

4

20.0 s

ON

1

2

3

4

3.0 s

ON

1

2

3

4

25.0 s

ON

1

2

3

4

4.0 s

ON

1

2

3

4

30.0 s

Fig. 4

Resetting the hybrid fuse

•

The hybrid fuse of the safety-monitoring module can be reset by

switching the operating voltage off and back on or by actuating

button S1.

•

Button S1 is located underneath the front cover of the safety-

monitoring module (see Fig. 2 and 3).

5.1 Notes

Delayed enabling circuits (see Fig. 5)

•

The DIP switches are located underneath the front cover of the

safety-monitoring module.

•

The safety enabling circuits 57-58 and 67-68 meet STOP category 1

to EN 60204-1.

•

The safety enabling circuits 13-14, 23-24 and 33-34 meet STOP

category 0 to EN 60204-1.

Signalling outputs (see fig. 6)

•

The input circuits are signalled through the signalling outputs Z1

(channel 1) and Z2 (channel 2).

•

The hybrid fuse of the safety-monitoring module can be reset by

switching the operating voltage off and back on or by actuating

button S1.

•

Button S1 is located underneath the front cover of the safety-

monitoring module.

•

The status of the hybrid fuse is signalled through signalling

output Y3. If the hybrid fuse is not activated, Y3 is supplied

with operating voltage.

58

57

68

67

+24 V

F3

23

22

Z1

Fig. 5

Fig. 6