23

SRB-E-232ST

Operating instructions

Safety-monitoring module

EN

8.4 Setting report

This report regarding the setting of the device must be completed

accordingly by the customer and enclosed in the technical

documentation of the machine.

The setting report must be available whenever a safety check is

performed.

Company:

The safety-monitoring module is used in the following machine:

Machine n°

Machine type

Module n°

Configured application (mode):

Set drop-out delay (t):

Set on (date)

Signature of the responsible person

8.5 Maintenance

A regular visual inspection and functional test, including the following

steps, is recommended:

1. Check the correct fixing of the safety-monitoring module

2. Check the cable for damages

3. Check electrical function

If a manual functional check is necessary to detect a

possible accumulation of faults, then this must take place

during the intervals noted as follows:

• at least every month for PL e with category 3 or

category 4 (according to ISO 13849-1) or SIL 3 with HFT

(hardware fault tolerance) = 1 (according to IEC 62061);

• at least every 12 months for PL d with category 3

(according to ISO 13849-1) or SIL 2 with HFT (hardware

fault tolerance) = 1 (according to IEC 62061).

Damaged or defective components must be replaced.

9. Disassembly and disposal

9.1 Disassembly

The safety-monitoring module must be disassembled in a de-energised

condition only.

9.2 Disposal

The safety-monitoring module must be disposed of in an appropriate

manner in accordance with the national prescriptions and legislations.

10.

Appendix

10.1

Wiring/circuit information

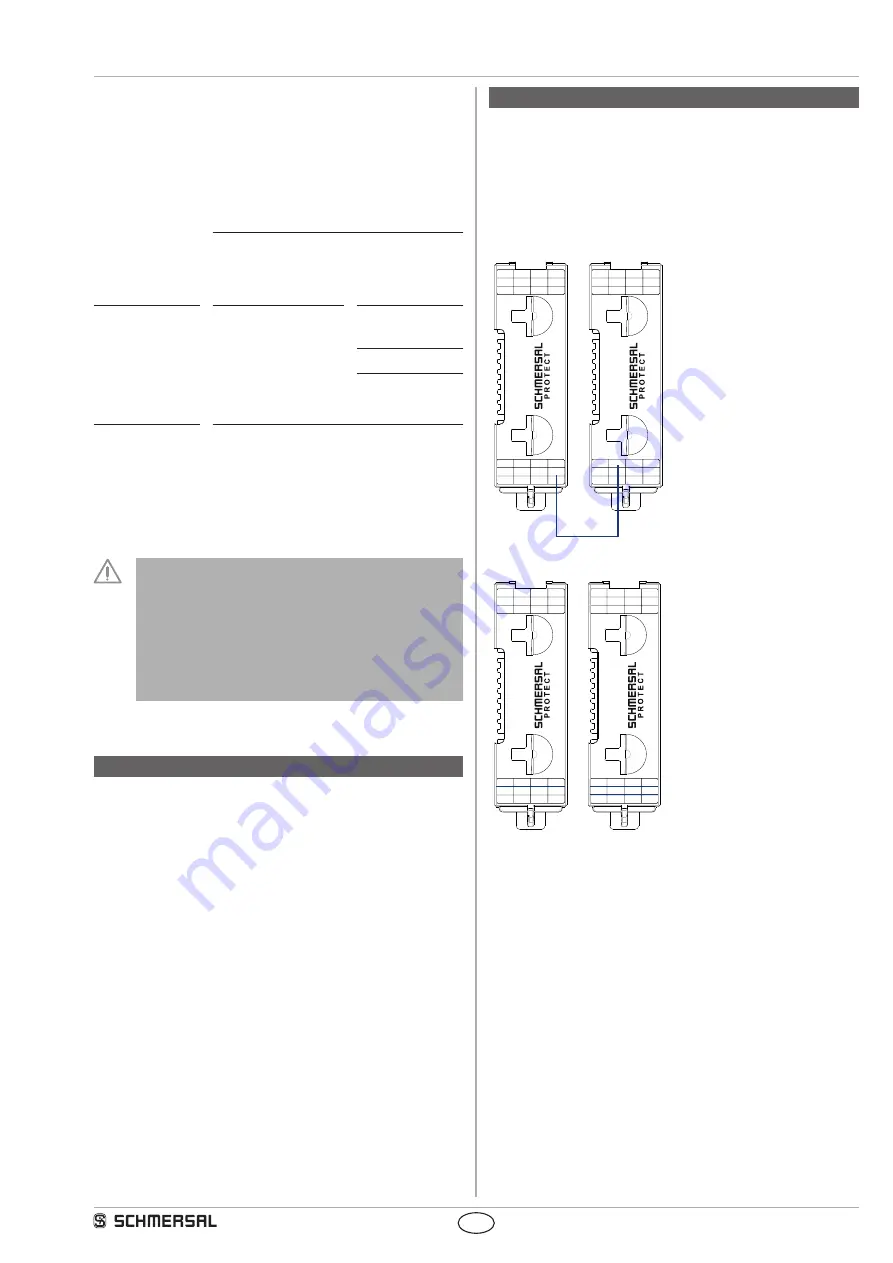

Wiring example for cascading via safety input X7:

Safety outputs of following SRB-E modules can be switched off in

each case via input X7.

For safety-orientated application, a fault in the wiring (short circuit to

24 V potential) must be able to be excluded!

1

0

S11 S12 S21 S22

A1

A2

X3

X2

X7

Qt1

Y2

Y1

S

R

B

-E

-2

12

ST

24

23

14

13

Out 2

time[s]

RUN

ERR

ln 1

ln 2

Out 1

mode

1

0

S11 S12 S21 S22

A1

A2

X3

X2

Q2

Q1

X7

Y1

S

R

B

-E

-2

3 2

ST

28

27

18

17

46

45

38

37

time[s]

RUN

ERR

ln 1

ln 2

Out 1

Out 2

mode

Air clearances and creepage distances of the safety contacts:

1

0

S11 S12 S21 S22

A1

A2

X3

X2

X7

Qt1

Y2

Y1

S

R

B

-E

-2

12

ST

24

23

14

13

Out 2

time[s]

RUN

ERR

ln 1

ln 2

Out 1

mode

1

0

S11 S12 S21 S22

A1

A2

X3

X2

Q2

Q1

X7

Y1

S

R

B

-E

-2

3 2

ST

28

27

18

17

46

45

38

37

time[s]

RUN

ERR

ln 1

ln 2

Out 1

Out 2

mode

Against all other connection terminals, the safety contacts 17-18 and

27-28 comply without additional measures with the requirements for

double insulation in accordance with IEC 60664-1 and are to be used

with switch voltages > 50 V. The safety contacts 37-38 comply with the

requirements for basic insulation.