5

TZM/TZF SPEZ

Operating instructions

Solenoid interlock

EN

Components with LED indication only for 24VDC. The

monitoring contacts of the LED versions are not potential-

free. In combination with these devices, only sequential

circuits can be used, in which both channels are controlled

with positive potential.

For the cable entry, suitable cable glands with an appropriate degree of

protection must be used.

After wiring, the wiring compartment must be cleaned (i.e. remove

excess cables etc.). The fixing screws of the wiring compartment cover

must be tightened with 0.8 Nm tightening torque.

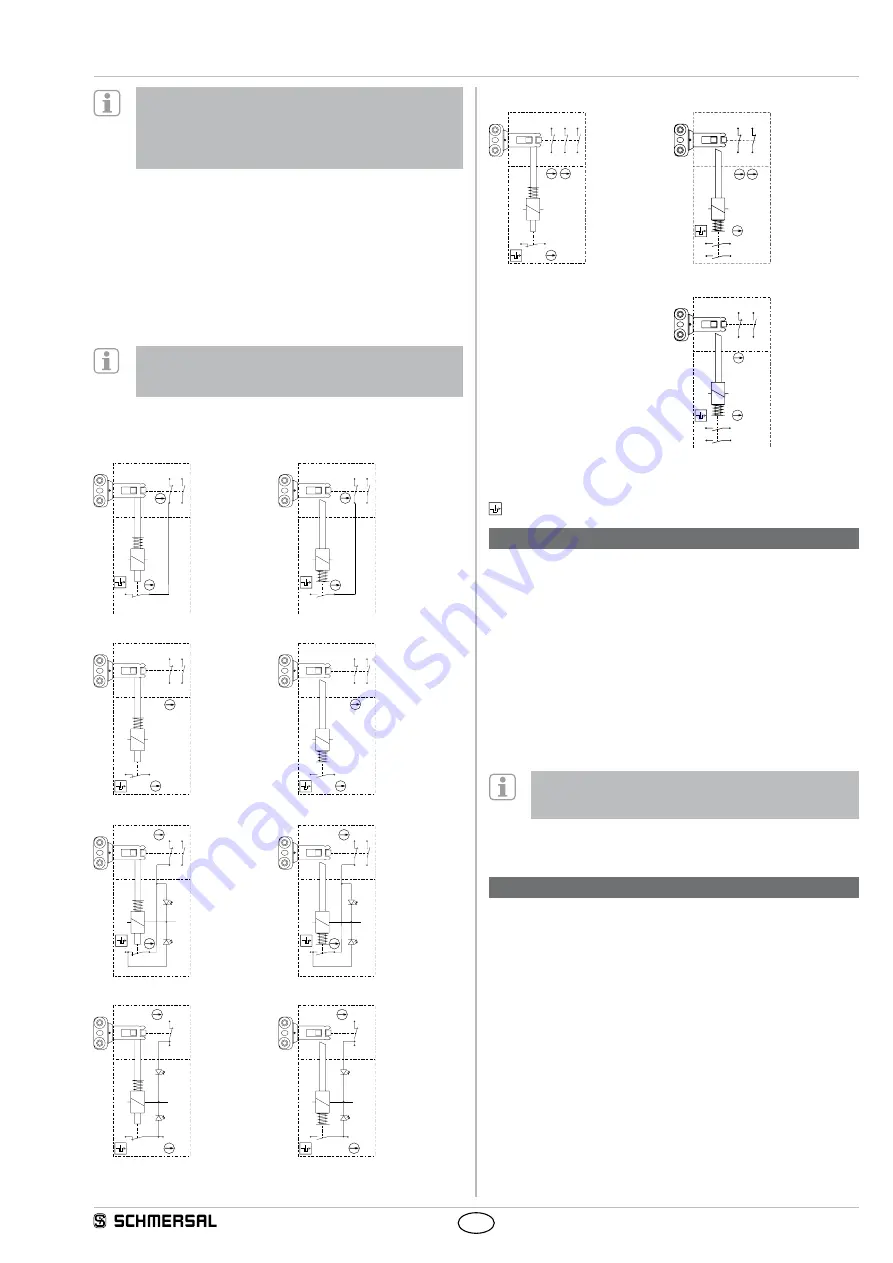

4.2 Contact variants

Contact variants are shown in a de-energised condition with

actuator inserted.

LED display:

1) Safety guard closed

2) Safety guard closed and locked

Power to unlock

Power to lock

TZF…

TZM…

21

E2

E1

11

12

33

34

22

21

22

E2

E1

11

33

34

12

TZFW…

TZMW…

21

22

E2

E1

11 33

12 34

21

22

E2

E1

11 33

12 34

TZFL

TZML

21

11 33

E2

gn

2

ye

1

22

E1

12 34

21

11 33

E2

gn

2

ye

1

22

E1

12 34

TZFWL

TZMWL

21

22

E1

E2

11

ye

1

gn

2

12

21

22

gn

2

ye

1

E2

E1

11

12

TZFW…3NC

TZMW4Ö

Power to unlock

Power to lock

21

22

E2

E1

41 33

11

12 42 34

21

22

E2

E1

11

12 42

41

32

31

TZMW...2MOE

21

22

E2

E1

42

41

33

11

12 34

Key

A

positive break NC contact

Monitoring the interlock according to ISO 14119

5. Set-up and maintenance

5.1 Functional testing

The safety function of the safety components must be tested.

The following conditions must be previously checked and met:

1. Fitting of the solenoid interlock and the actuator.

2. Check the integrity of the cable entry and connections.

3. Check the switch enclosure for damage.

5.2 Maintenance

A regular visual inspection and functional test, including the following

steps, is recommended:

1. Check for tight installation of the actuator and the switch.

2. Remove particles of dust and soiling.

3. Check cable entry and connections.

Adequate measures must be taken to ensure protection

against tampering either to prevent tampering of the safety

guard, for instance by means of replacement actuators.

Damaged or defective components must be replaced.

6. Disassembly and disposal

6.1 Disassembly

The safety switchgear must be disassembled in a de-energised

condition only.

6.2 Disposal

The safety switchgear must be disposed of in an appropriate manner in

accordance with the national prescriptions and legislations.