3

TZG

Operating instructions

Safety switch

EN

60

30

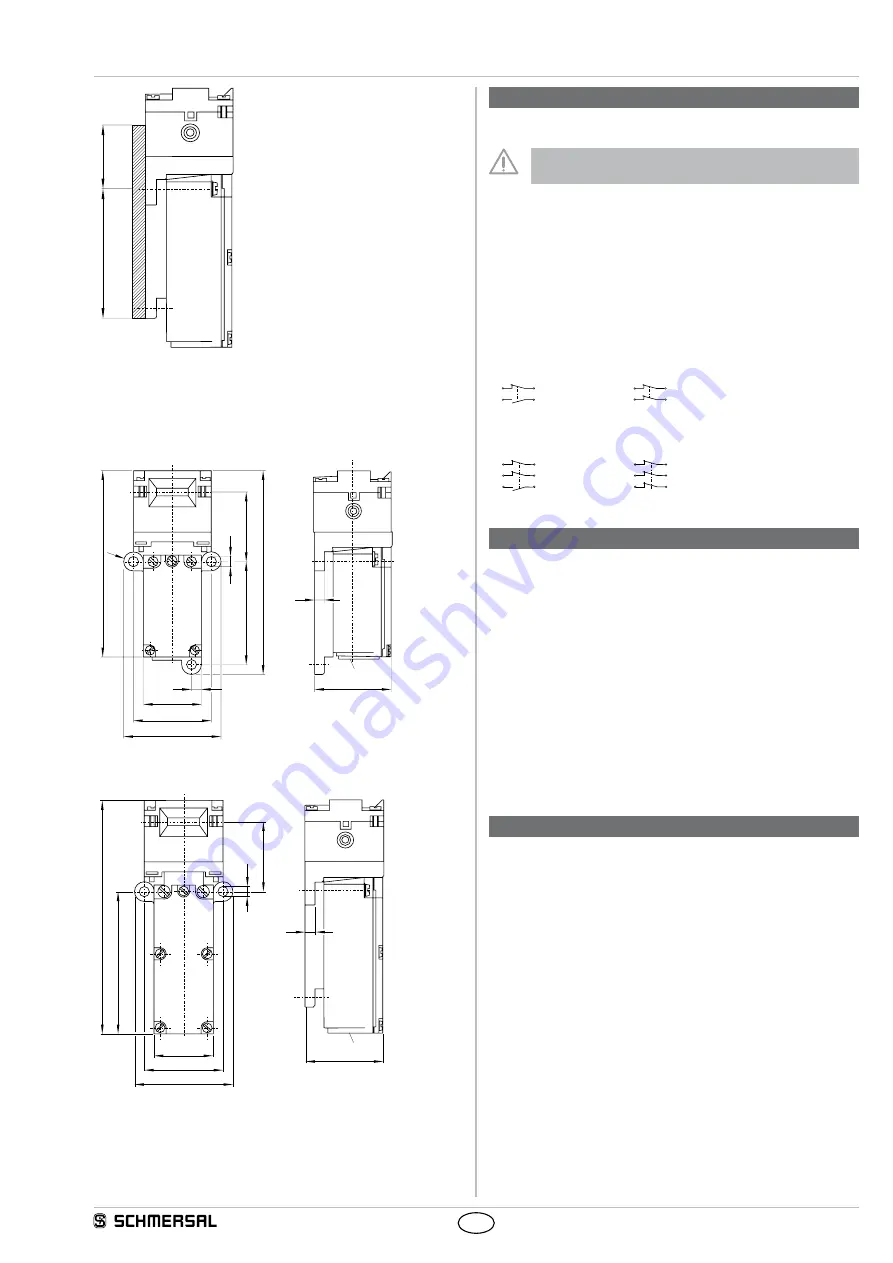

3.2 Dimensions

All measurements in mm

TZG 2-pole / TZGP

35

5

39,5

30

50

39,5

R5

96.5

10

5.3

106.5

55

M20 x 1,5

TZG 3-pole

5

39,5

30

50

39,5

122

75,5

35

5.3

M20 x 1,5

4. Rear side Electrical connection

4.1 General information for electrical connection

The electrical connection may only be carried out by

authorised personnel in a de-energised condition

The contact labelling can be found in the wiring compartment of the

switch For the cable entry, only suitable plastic cable glands with an

appropriate degree of protection must be used After wiring, dust and

soiling must be removed from the wiring compartment The safety

switch is double insulated The use of a protective ground connector

therefore is not authorised

4.2 Contact variants

Contacts are shown with safety guard closed

TZG../103 / TZGP

TZG../110

11

23

12

24

11

21

12

22

TZG../1103

TZG../3330

11

21

33

12

22

34

11

21

31

12

22

32

5. Set-up and maintenance

5.1 Functional testing

The safety function of the safety components must be tested

The following conditions must be previously checked and met:

1 Check the free movement of the actuating element

2 Check the integrity of the cable entry and connections

3 Check the switch enclosure for damage

5.2 Maintenance

A regular visual inspection and functional test, including the following

steps, is recommended:

1 Check the free movement of the actuating element

2 Remove particles of dust and soiling

3 Check cable entry and connections

Damaged or defective components must be replaced.

6. Disassembly and disposal

6.1 Disassembly

The safety switchgear must be disassembled in a de-energised

condition only

6.2 Disposal

The safety switchgear must be disposed of in an appropriate manner in

accordance with the national prescriptions and legislations