60

Elevator positioning system USP 30 / 100

Installation of the actuating magnets

In order to achieve optimum correction values, you

should distribute 5 actuating magnets equally along the

shaft, i.e., if the shaft extends over 10 floors, then an ac-

tuation magnet should be installed at every second floor.

If less than 5 actuating magnets are used the accuracy of

the system decreases.

Go onto the roof of the elevator cabin with the actuating

magnets and travel in ”inspection travel” mode up to the

shaft head.

It is advisable to attach the actuating magnets to elements

that are firmly fixed to the shaft door (chamfer or threshold of

the floor). Ensure that the actuation magnet is not located on a

moving part and is installed so that it aligns precisely with the

correction sensor.

It has to be ensured, that the correction sensor drives by

the actuating magnet with a minimum speed of 0.1 m/s.

The correction sensor and the actuating magnets should

not be facing each other at the levelling position. Be-

tween the actuating magnet and other magnet switches

should be a safety distance of min. 0.5 m.

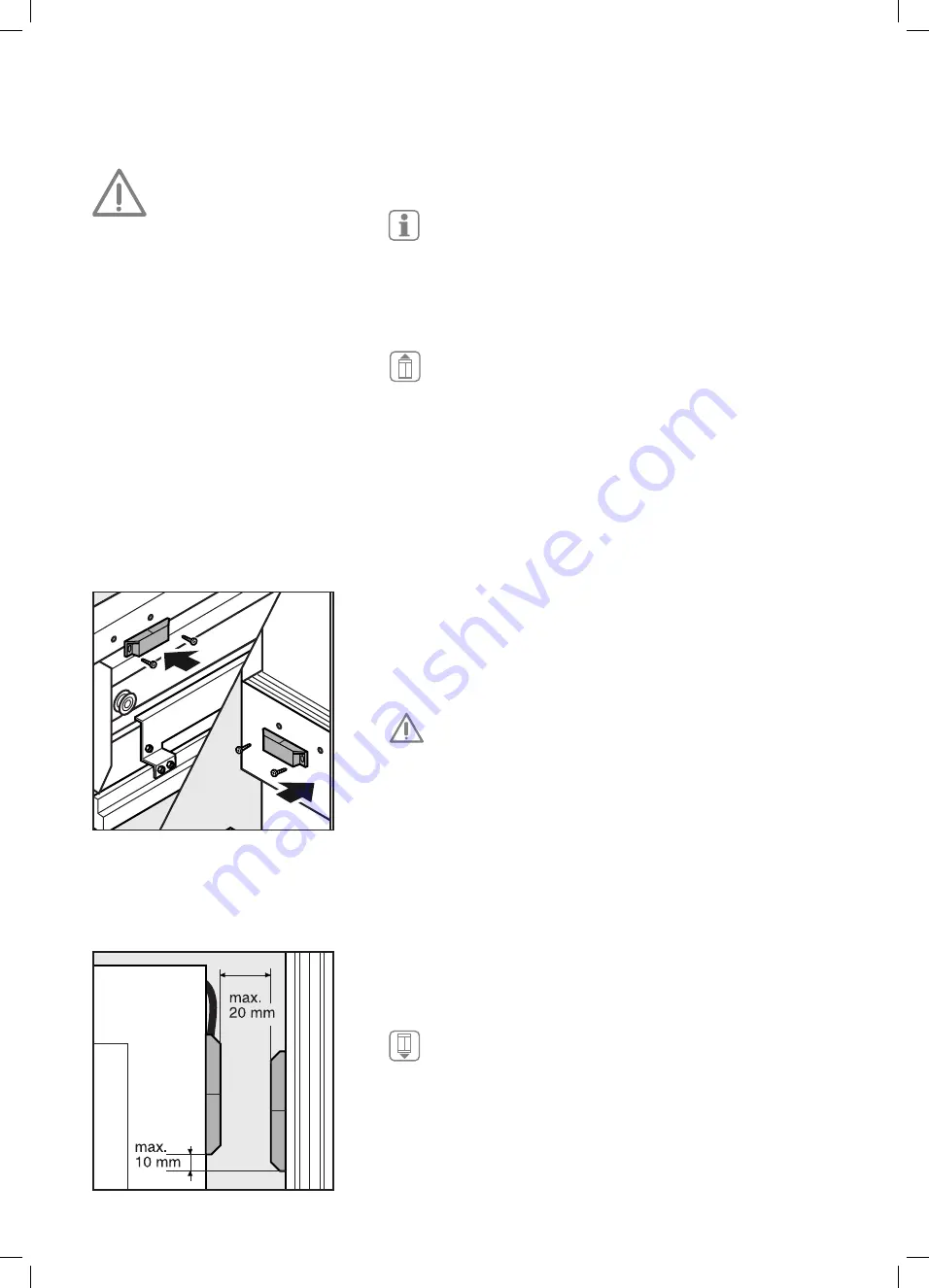

Each actuation magnet must be installed so that there is a maxi-

mum horizontal clearance of 20 mm between the correction sen-

sor and the actuation magnet. This figure may not be exceeded.

The sideways offset (vertical level) must be less than 10 mm.

Travel down in ”inspection travel” mode and install the

remaining actuating magnets on the same principle as

described above at points where the elevator cabin with

the correction sensor travel and pass frequently.

19

20

Functional errors due to incor-

rectly installed components!

Ensure that the actuating magnets

are installed correctly so that neit-

her the correction sensor nor any

other parts can be touched by the

moving elevator cabin.

The correction sensor only receives

pulses, if all actuating magnets are

installed in alignment with the sen-

sor and the maximum distances are

observed.

View from

top

USP_Montage_GB.indd 60

18.02.2013 15:39:46