EFA bung dropper Translation of the original operating instructions

EN

V 05.2021

18 of 27

min. EFA 202: 126 mm

EFA 203: 182 mm

EFA 204: 151 mm

max. EFA 202: 139 mm

EFA 203: 195 mm

EFA 204: 165 mm

13

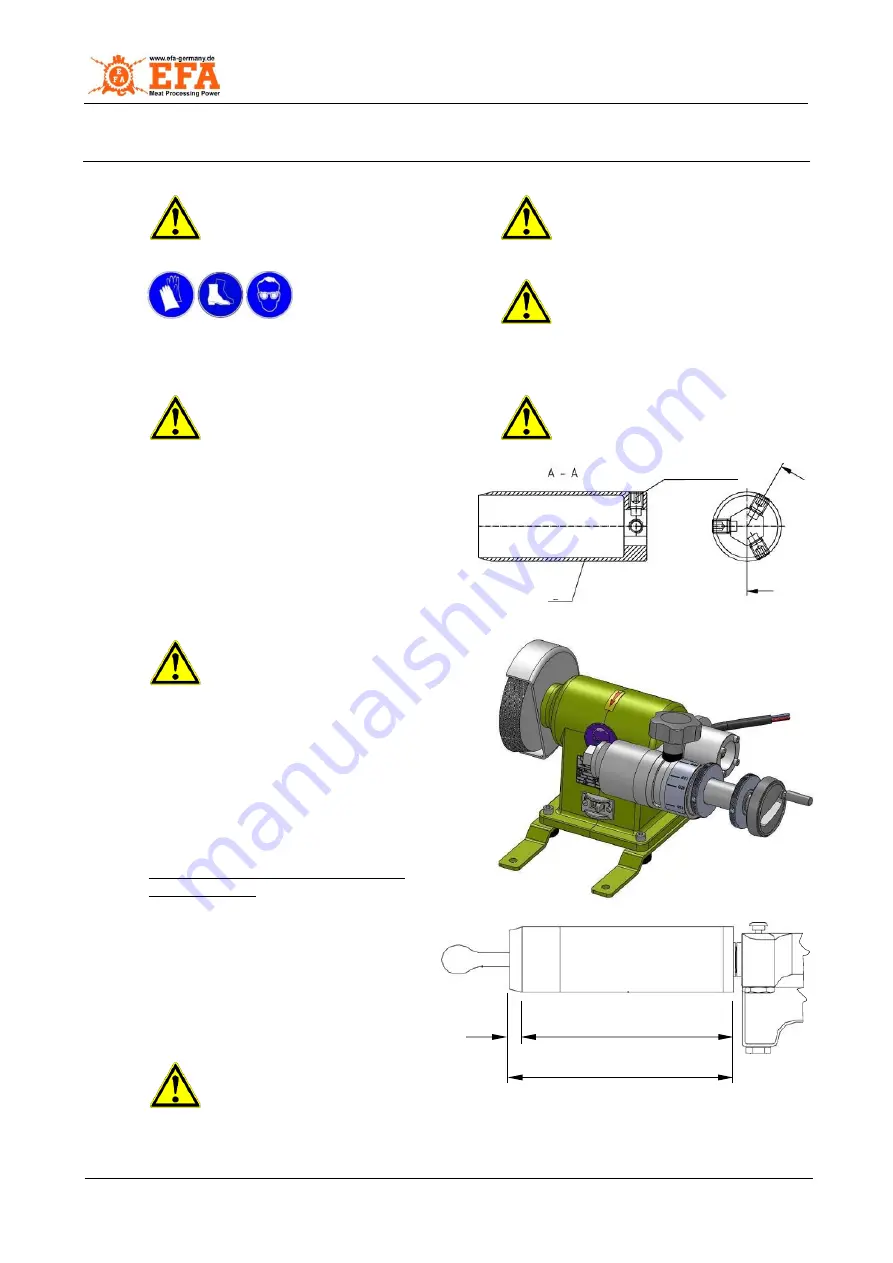

Fig. 6.4

– Grinding machine

EFA SM 2

A

– A

1 (3x)

2

A

A

7

Assembly

Danger!

Assembly work is only

allowed to be carried out by

authorised specialist

personnel.

Danger!

Disconnect the device from the

compressed air network prior to

performing any assembly work!

Warning!

Wear cut-resistant gloves,

safety shoes and protective

goggles during all assembly

work or when sharpening the

blades.

Danger!

Observe the assembly

sequence!

7.1

Change of blades

Danger!

Never reach into the cutting

area of the rotating blades,

otherwise you could cut off

limbs!

Warning!

Only use a genuine EFA blade!

1) Unscrew screws (1), 3x, one after the

other.

2) Pull the blade (2) off the hexagonal holding

fixture.

3) Assembly in reverse order.

Tighten the 3 screws (1) evenly.

Ensure that the blade runs true.

Danger!

Do not leave any tool keys

connected. Check that the blade is

tight and the keys are removed

before switching on.

7.2

Sharpening the blade

We have established a sharpening service in our

Service department. The blades are resharpened

with the grinding machine EFA SM 2.

Incorrectly resharpened blades result in

production losses or a considerable hazard for

the user.

Also read the instructions supplied with the

grinding machine.

Holding fixtures for both blade lengths

(139 + 195 mm) are supplied.

The minimum blade length,

see Fig. 6.5

:

- EFA 202 is 126 mm

- EFA 203 is 182 mm

- EFA 204 is 151 mm

Danger!

Proficient resharpening by hand

is not possible.

Fig. 6.3

– Change of blades

Fig. 6.5

– Blade length