UNM Base / CPM Base

II/11

GB

Store the compressor in a dust-free and dry

area where it is not exposed to high tem-

perature fluctuations.

2.7.2 Environment

Do not dispose of the device in

household waste!

Recycle de-

vices, accessories and packaging. Observe

applicable country-specific regulations.

EU only:

European Directive 2002/96/EC

stipulates that used electric power tools must

be collected separately and disposed of at an

environmentally responsible recycling cen-

tre.

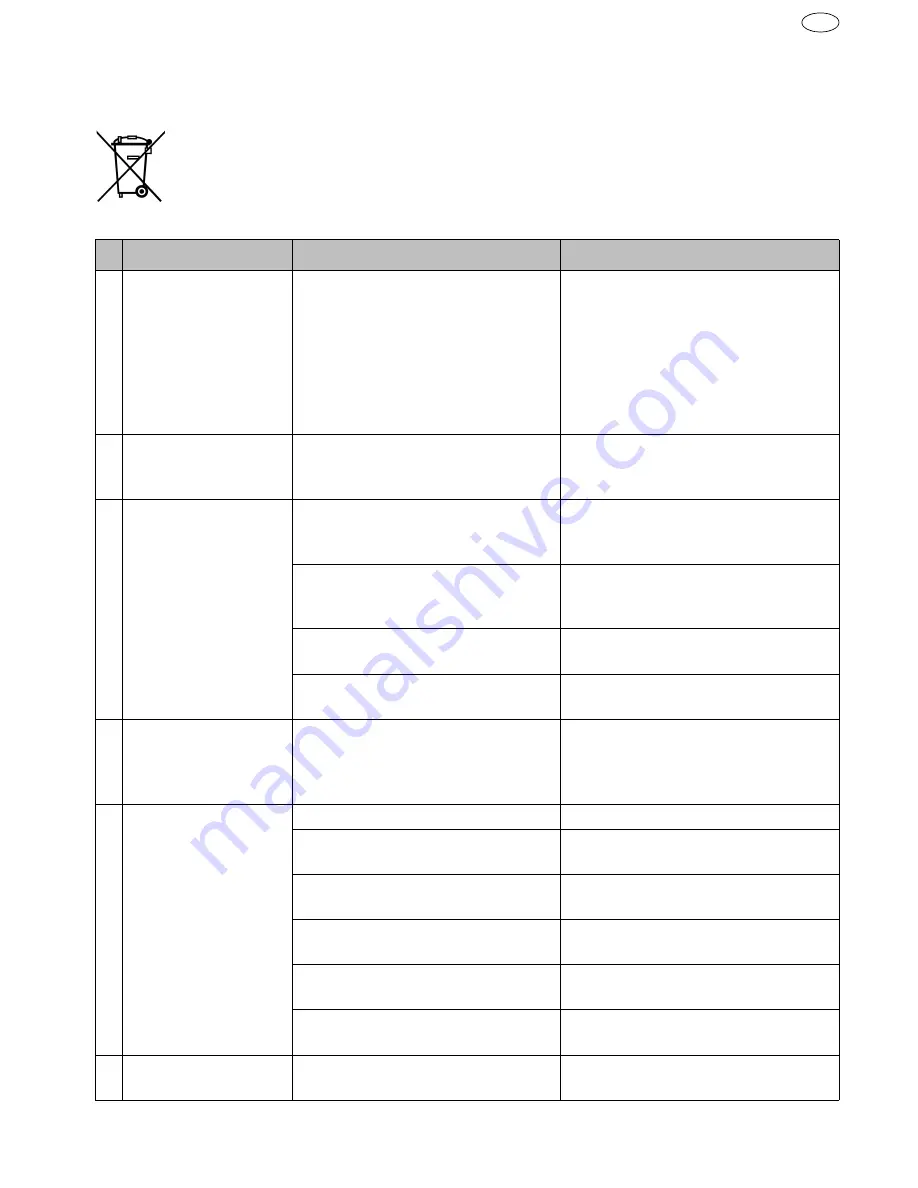

2.8 Troubleshooting

Problem

Cause

Remedy

A Protective motor

switch interrupts

power supply

In case of malfunctions (e.g.

overheating; low voltage;

extension cable too long or with

incorrect cross-section), the

protective motor switch is

tripped.

Switch off the compressor. Wait

a short while. Actuate the pro-

tective motor switch is avail-

able. Switch on the compressor.

Protective motor switch trips

again: switch off compressor.

Disconnect the power supply.

Contact the service partner

B Pressure relief does

not function

Power failure / undervoltage in

mains with compressor switched

on

Switch off the compressor. It

depressurises. Switch on the

compressor

C Compressor does

not start when

switched on.

Vessel pressure is higher than

switch-on pressure.

Relieve pressure in the vessel

until the pressure switch is acti-

vated automatically.

Power supply faulty.

Have the power supply checked

by a qualified person (service

partner).

Protective motor switch inter-

rupts power supply.

See item A.

Pressure switch defective

Have the pressure switch

changed by a qualified person.

D Compressor starts

up briefly / buzzes

and then switches

off automatically

Mains connection cable longer

than permitted or the cross sec-

tion is too small

Check connection cable length

and cable cross-section (see

Chap. 2.4.4)

E Compressor runs

continuously

Intake filter badly contaminated

Clean or replace

Air consumption of compressed

air tools is too high

Check air consumption. Contact

the service partner

Leakage at compressor

Locate leak, contact service

partner

Excessive condensate in the

tank

Drain the condensate (see

Chap. 2.6.3)

Compressed air line leaky

Check the compressed air net-

work, seal leak

Condensate drain valve is open

or missing

Close or replace

F Load-relieving valve

is blowing off

Load-relieving valve leaky

Clean or replace

Summary of Contents for A202002

Page 2: ......

Page 7: ...1a...

Page 16: ...I 8 UNM Base CPM Base RUS 10...

Page 59: ...UNM Base CPM Base II 43 RUS 2 7 2 2002 96 EG 2 8 A B C A D 2 4 4...

Page 60: ...II 44 UNM Base CPM Base RUS E 2 6 3 F G 2 6 9 H 2 6 3 E I J...

Page 61: ...UNM Base CPM Base II 45 RUS 2 9 K L 2 6 8...

Page 66: ......

Page 67: ......