UNM STS/STL

II/3

GB

Prevent the vessel from emptying completely

during longer downtimes***:

Close ball valve (item 22).

2.5.1 Insert

1. Connect the compressor to the mains

power supply.

2. Switch on the compressor at the ON/OFF

switch (item 10) or the main switch.

Compressor starts up and switches off

automatically: the compressor is ready

for use.

When the switch-on pressure is reached, the

compressor restarts automatically.

2.5.2 Compressed air bleeding

Install the elastic connecting hose between

the ball valve (item 22) and compressed air

pipe system or compressed air cold dryer.

2.5.3 After use

1. Switch on the compressor at the ON/OFF

switch (item 10).

2. Interrupt the power supply to the main

switch.

2.6 Maintenance

2.6.1 Before each maintenance task

1. Switch off compressor at the ON/OFF

switch (item 10) (if available). Discon-

nect power supply at main switch.

3. Depressurise the whole compressor:

slowly open the ball valve condensate

drainage (item 09) and close it if no

more air escapes.

2.6.2 Cleaning the compressor

• Clean the cooling fins on the cylinder, cyl-

inder head and aftercooler using com-

pressed air.

• Clean the fan impeller cover on the motor.

2.6.3 Draining condensate from pres-

sure vessel

L

Condensate is a water pollutant. Dispose

of it according to applicable regulations!

1. Place a suitable vessel under the conden-

sate drain.

2. To drain condensate, the pressure must

be approx. 2 bar.

3. Open the ball valve (item. 09) and close

it if no more condensate runs out

2.6.4 Checking the oil level

1. The oil level must be between the top

and bottom marks (oil dipstick/oil in-

spection glass). (Figure 4a)

2. Correct if necessary.

L

If oil is milky, it must be changed imme-

diately.

2.6.5 Changing/adding oil

1. Allow the compressor to warm up, switch

it off, disconnect the power supply.

2. Pull out oil filler plug or hose (item 03),

hold used oil container under the mini

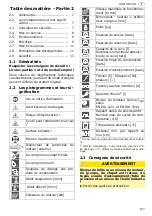

Interval / No later than Tasks

See chap.

-- / As needed

Clean compressor

2.6.2

-- / after each use

Drain condensate from pressure vessel

2.6.3

daily / commissioning

Check the oil level, add oil if necessary.

2.6.4

Once after 10 h / --

Check screw connections

2.6.6

-- / Weekly

Check intake filter

2.6.7

50 h / After 6 months

Check V-belt tension (where applicable)

2.6.9

Clean intake filter

2.6.7

Change oil (1st oil change mineral or synthetic oil) 2.6.5

500 h / after 1 year

Change oil (with mineral oil)

2.6.5

Change intake filter

2.6.7

Change check valve and insert

2.6.10

Check screw connections

2.6.6

1,000 h / after 2 years

Change oil (with synthetic oil)

2.6.5

Change V-belts (where applicable)

2.6.9

2,500 h / After 5 years

Change safety valve

2.6.11

Summary of Contents for UNM STS 1000-10-270

Page 10: ...2a 3a 4a 7a 7b 5a SB 2b 2c S 6a...

Page 55: ......