13

3. Settings.

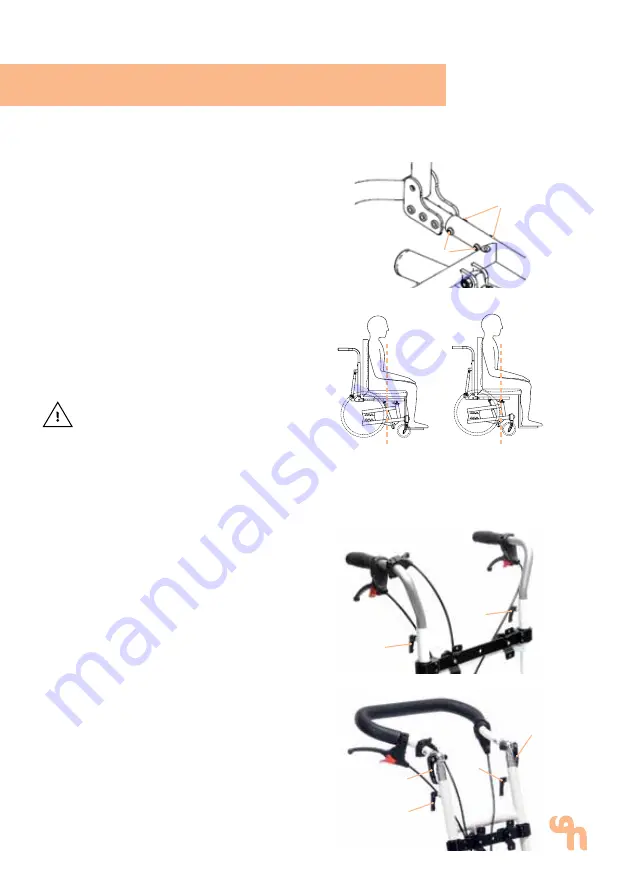

3.6 Adjustment of the back unit

(positioning of a seat pan / seat unit)

The complete back unit can be adjus-

ted in the depth of the seat pan / seat

unit. To do this, remove the 4 screws (

A

)

on the right and left of the top frame

and slide the back unit out or in. Then

install the screws again (

A

) and re-tigh-

ten them firmly. Ensure that the seat

pan / seat unit is positioned centrally

on the subframe (Fig. 1). Only in this way

can be subframe be used optimally. If

the centre of gravity of the seat pan /

seat unit lies on the front wheels (Fig.

2), the manoeuvrability of the subframe

will be adversely affected.

The seat pan / seat unit must be

placed centrally on the subframe.

3.7 Push handles

The height of push grips can be individually adjusted on your Freddy. This

takes place after loosening the two clamp levers (

B

) on the rear tubes. Tigh-

ten the clamp lever again after adjust-

ment.

3.8 Push handle

The design with the push handle is a

more comfortable solution. The angle

of the push handle can be individually

adjusted in addition to height adjust-

ment using the joints with quick release

(

C

). The height is adjusted after loo-

sening the two clamp levers (

D

) on the

rear tubes. The clamp lever and quick

release must be tightened again after

adjustment.

ü

Abb. 1

x

Abb. 2

A

A

A

A

C

D

D

C