15

4. Cleaning and maintaining.

4.3.1 Maintenance specifications

• Basic cleaning according to the manufacturer's specifications

• Disinfect according to the manufacturer's specifications as required

• Damages to the frame, mounting parts and accessories (cracks, breaks,

corrosion, bent or missing parts)

• Strength of the connections (tighten loose screws, replace missing

screws)

• Functionality of the adjustment elements (screws, release lever, latching

elements, foot pedal)

• Functionality of other adjustment elements (push bar and footrests)

• Functionality of the gas pressure springs (if necessary readjustment of

thebowden cables)

• Functionality of the safety elements (anti-tilt)

• Functionality of brakes

• Functionality of the rollers (concentricity, smooth running)

• Legibility of the type label

• Final complete functional check of the aid

• Check that all mounting parts and associated accessories are correctly

fastened

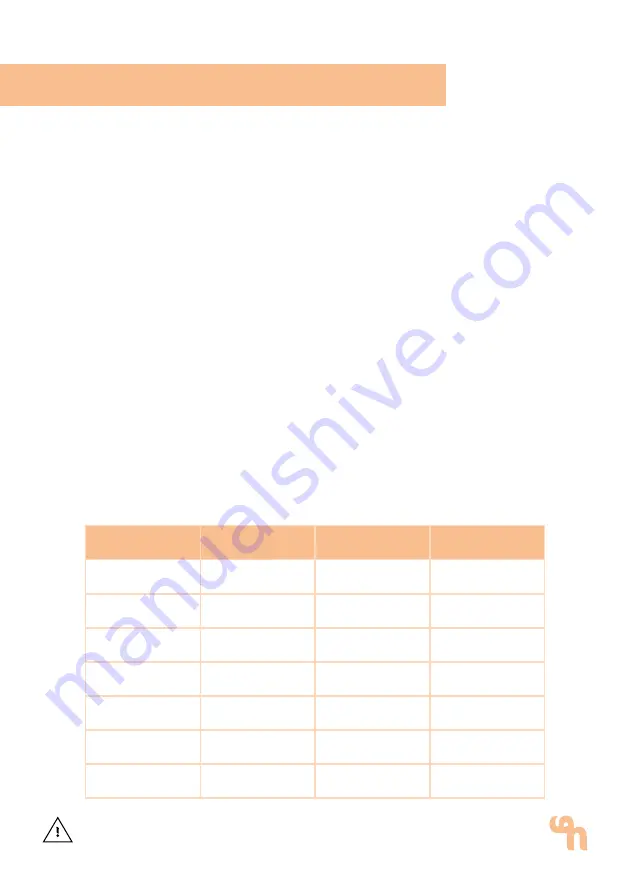

4.3.2 Maintenance plan

Maintenance specifications of the manufacturer (see

Point 4.3.1

) were car-

ried out:

Date

Company

Name

signature

Any defects or damage found must be repaired by the specialist dealer or the

manufacturer before reuse.