OPERATION

FX-530 06/21

Operation Section 4-45

© 2021 Alamo Group Inc.

OPERA

TION

13. CUTTER STORAGE

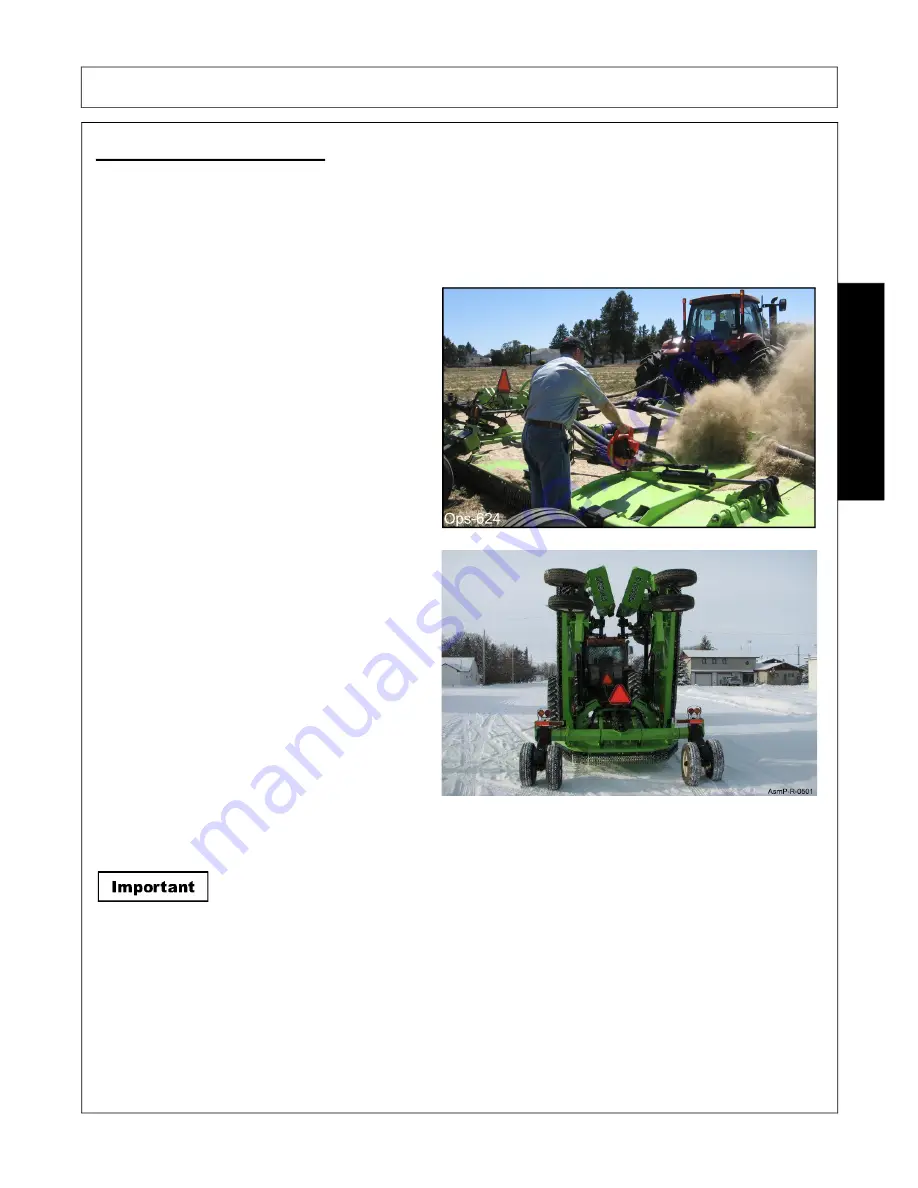

It is recommended that the Cutter be stored with the center section and both wings fully lowered to ground

level. If the cutter is stored with the wings in the raised position, select a level area and install wing transport

pins to prevent the wings from falling BEFORE disconnecting the cutter hitch from the tractor.

Properly preparing and storing the mower at the end of the season is critical to maintaining its appearance

and to help ensure years of dependable service. The following are suggested storage procedures:

•

Clean any dirt or debris off the mower deck.

•

Scrape any accumulated cuttings off the under

side of the deck. Coat the deck underside and

any other exposed metal surfaces with oil to

prevent rusting.

•

If the implement is left unused for an extended

period of time, install the transport pins.

Retract the center cylinder completely.

Retracting the cylinder rods will prevent

rusting, ensure that the cylinders are full of oil

and relieve pressure in the hydraulic circuit. If

the cylinder rods are not retracted, smear

grease over exposed rods.

•

Apply grease to exposed threaded adjustment

screws. These include the cylinder depth stop

collar and the frame leveling rod.

•

Install the hitch jack on the jack mount located

on the outer hitch frame.

•

Lubricate all implement grease points and fill

gearbox oil levels as detailed in the

maintenance section.

•

Store the tractor shaft in the holder keep the

driveline yoke from sitting in water, dirt and

other contaminants.

•

Use spray touch-up enamel where necessary

to prevent rust and maintain the appearance of

the implement.

•

Tighten all bolts and pins to the recommended

torque.

When disconnecting from the tractor for short period of time, swing the PTO support upright and lay the PTO

driveline into the cradle. When storing the implement for an extended period of time, it is recommended the

driveline be removed from the machine and stored inside.

When connecting the cutter to the tractor, ensure the PTO support is swung down, and out

of the way.

It is critical that driveline clutches slip when an obstacle or heavy load is encountered to avoid implement and/

or tractor damage. If the implement sits outside for an extended period of time or is exposed to rain and/or

humid air, the clutch lining plates must be inspected to ensure they are not frozen together from rust or

corrosion. If the implement has been exposed to such conditions, at the start of each season, and any time it

is suspected that the slip clutch plates may be frozen together, readjust the slip clutch as detailed in Slip

Clutch Maintenance of the maintenance section in this manual.

OPS-R-0032_P

Summary of Contents for FX-530

Page 2: ......

Page 10: ......

Page 11: ...Safety Section 1 1 2021 Alamo Group Inc SAFETY SECTION ...

Page 29: ...SAFETY FX 530 06 21 Safety Section 1 19 2021 Alamo Group Inc SAFETY Decal Description ...

Page 30: ...SAFETY FX 530 06 21 Safety Section 1 20 2021 Alamo Group Inc SAFETY ...

Page 31: ...SAFETY FX 530 06 21 Safety Section 1 21 2021 Alamo Group Inc SAFETY ...

Page 32: ...SAFETY FX 530 06 21 Safety Section 1 22 2021 Alamo Group Inc SAFETY ...

Page 33: ...SAFETY FX 530 06 21 Safety Section 1 23 2021 Alamo Group Inc SAFETY ...

Page 34: ...SAFETY FX 530 06 21 Safety Section 1 24 2021 Alamo Group Inc SAFETY ...

Page 35: ...SAFETY FX 530 06 21 Safety Section 1 25 2021 Alamo Group Inc SAFETY ...

Page 36: ...SAFETY FX 530 06 21 Safety Section 1 26 2021 Alamo Group Inc SAFETY ...

Page 37: ...SAFETY FX 530 06 21 Safety Section 1 27 2021 Alamo Group Inc SAFETY ...

Page 39: ...Introduction Section 2 1 2021 Alamo Group Inc INTRODUCTION SECTION ...

Page 45: ...Assembly Section 3 1 2021 Alamo Group Inc ASSEMBLY SECTION ...

Page 58: ...ASSEMBLY FX 530 03 21 Assembly Section 3 14 2021 Alamo Group Inc ASSEMBLY ...

Page 60: ......

Page 61: ...Operation Section 4 1 2021 Alamo Group Inc OPERATION SECTION ...

Page 115: ...Maintenance Section 5 1 2021 Alamo Group Inc MAINTENANCE SECTION ...

Page 119: ...MAINTENANCE FX 530 06 21 Maintenance Section 5 5 2021 Alamo Group Inc MAINTENANCE ...

Page 135: ...MAINTENANCE FX 530 06 21 Maintenance Section 5 21 2021 Alamo Group Inc MAINTENANCE ...

Page 136: ...SEGURIDAD FX 530 06 21 Sección de Seguridad 1 29 2021 Alamo Group Inc SEGURIDAD ...

Page 137: ...SEGURIDAD FX 530 06 21 Sección de Seguridad 1 28 2021 Alamo Group Inc SEGURIDAD ...

Page 138: ...SEGURIDAD FX 530 06 21 Sección de Seguridad 1 27 2021 Alamo Group Inc SEGURIDAD ...

Page 139: ...SEGURIDAD FX 530 06 21 Sección de Seguridad 1 26 2021 Alamo Group Inc SEGURIDAD ...

Page 140: ...SEGURIDAD FX 530 06 21 Sección de Seguridad 1 25 2021 Alamo Group Inc SEGURIDAD ...

Page 141: ...SEGURIDAD FX 530 06 21 Sección de Seguridad 1 24 2021 Alamo Group Inc SEGURIDAD ...

Page 142: ...SEGURIDAD FX 530 06 21 Sección de Seguridad 1 23 2021 Alamo Group Inc SEGURIDAD ...

Page 143: ...SEGURIDAD FX 530 06 21 Sección de Seguridad 1 22 2021 Alamo Group Inc SEGURIDAD ...

Page 144: ...SEGURIDAD FX 530 06 21 Sección de Seguridad 1 21 2021 Alamo Group Inc SEGURIDAD ...

Page 145: ...SEGURIDAD FX 530 06 21 Sección de Seguridad 1 20 2021 Alamo Group Inc SEGURIDAD ...

Page 146: ...SEGURIDAD FX 530 06 21 Sección de Seguridad 1 19 2021 Alamo Group Inc SEGURIDAD ...

Page 147: ...SEGURIDAD FX 530 06 21 Sección de Seguridad 1 18 2021 Alamo Group Inc SEGURIDAD ...

Page 164: ...Sección de Seguridad 1 1 2021 Alamo Group Inc SECCIÓN DE SEGURIDAD ...

Page 165: ......