WSI 100 / 125 / 150 / 200 / 250 / 300

page

9

2

Transport / Storage / Installation

2.1

Transport and storage

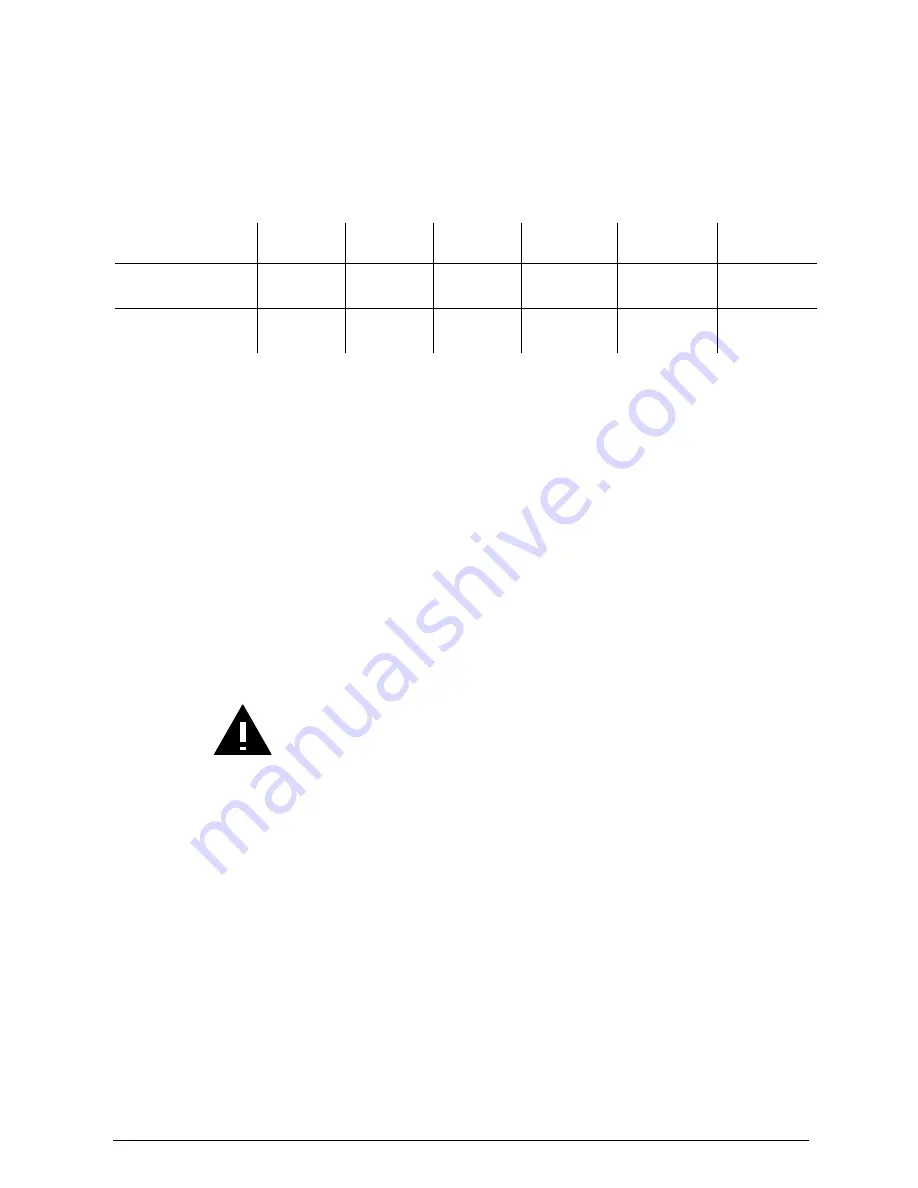

2.1.1 Dimensions

Packing

dimensions

WSI 100

WSI 125

WSI 150

WSI 200

WSI 250

WSI 300

without socle

in mm

960x800x1480

960x970x1480

960x970x1480

1150x910x1665

1150x1080x1665

1150x1080x1665

with socle

in mm

960x800x1690

960x970x1690

960x970x1690

1150x910x1900

1150x1080x1900

1150x1080x1900

2.1.2 Fastening points for lifting devices

The machines are delivered on pallets which can be transported by fork lift trucks.

2.1.3 Storage conditions

The machines are to be stored in a dry, frost-free place.

2.2

Instructions for unpacking

The return of undamaged packing material into the material cycle saves on raw materials and

reduces the occurrence of waste. The Schulthess company or your authorised

specialist dealer will generally gladly take the packing back.

If you dispose of the transport packing yourself, please take it sorted to your local

authority's nearest material recycling centre.

The red transport safety catches, or possibly transport rails, fastening plates and the wooden

transport base, as well as the other wooden parts can also be returned if not used.

Important!

Packing material is not a plaything for children.

2.3

Instructions for installation, alignment, fastening

2.3.1 General

•

The washing machine may only be installed and put into operation by our Customer Service

or an authorised specialist dealer.

•

In the event of great differences between the temperature during transport and that at the

place of installation, you must wait for twelve hours before putting the machine into operation.

Any condensation which may have formed in the appliance can dry out in this period.

•

Do not connect a damaged appliance (e.g. transport damage). In case of doubt, contact our

Customer Service department.

•

Do not install the washing machine in rooms exposed to frost.

•

The washing machines are not explosion proof. Therefore, do not use the washing machine

in rooms in which inflammable or explosive gases or vapours occur.