9

AIR COMPRESSOR - OWNER'S MANUAL

AIR COMPRESSOR - OWNER'S MANUAL

40

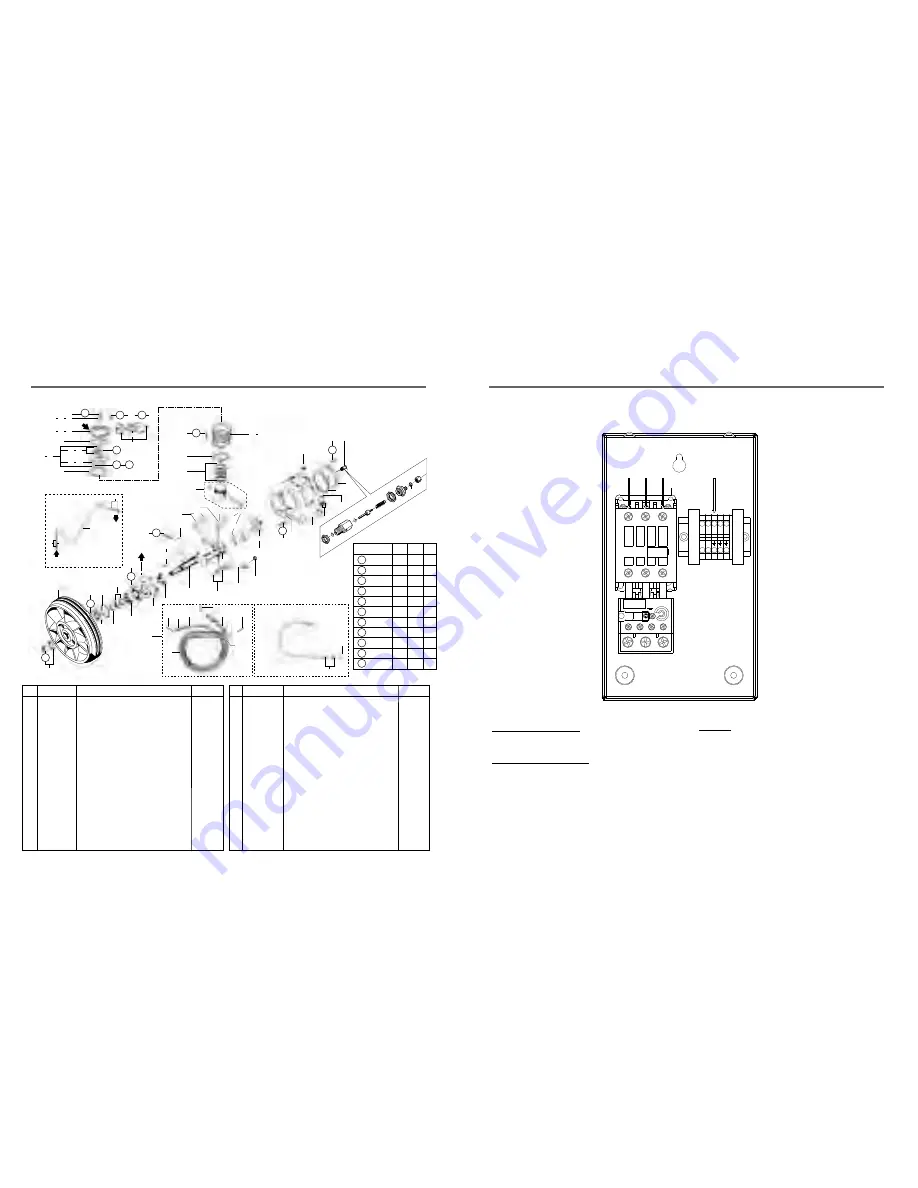

INSTALLATION

K1

1 L1

3 L2

5 L3

A1

A2

96 NC

95 NC

X1

FT1

PE

L3

L1

L1: "PHASE 1" CONDUCTOR

L2: "PHASE 2" CONDUCTOR

L3: "PHASE 3" CONDUCTOR

MAKE LEADS "L1", "L2", "L3" AND "PE" TO "1 L1", "3 L2",

MANUFACTORY WIRES LEADS:

"96 NC" CONECTED TO "A1"

"5 L3" CONECTED TO "A2" *

"1 L1" CONECTED TO "RED BUTTON" **

"RED BUTTON" CONECTED TO "X1.2"

"X1.2" CONECTED TO "PRESSURE SWITCH"

"PRESSURE SWITCH" CONECTED TO "X1.1"

"X1.1" CONECTED TO "95 NC"

2 T1

4 T2

6 T3

"X1.4" AND "X1.5" CONECTED TO "PRESSURE SWITCH" AND "MOTOR"

"2 T1", "4 T2" AND "6 T3" CONECTED TO "MOTOR"

CUSTOMER WIRES LEADS:

L2

PE: "PROTECTIVE" CONDUCTOR (GROUND)

"5 L3" AND "X1.3" RESPECTIVELY, KEEPTING THE OTHERS CONDUCTORS;

WARNING:

- COMPRESSOR FLYWHEEL ROTATION SHOULD BE COUNTERCLOCKWISE

WHEN FACING FLYWHEEL

- IF COMPRESSOR FLYWHEEL ROTATION IS REVERSED (CLOCKWISE), QUICLY

TURN OFF THE POWER AND DISCONNECT ALL SUPPLY SOURCE AND

INTERCHANGE THE "L1" AND "L2" WIRES.

NOTE

:

The

“

wiring procedure

”

is only for reference also

“

Electrical Diagram

”

see page 5.

* For the product version in 460V:

The command wiring is carried out by a step-down transformer from 460V to 230V

as showed on page 5 by T

”

.

“

- TURN OFF POWER BEFORE SERVICING

X1

THREE - PHASE

1 2

1 2

3 4 5

3 4 5

WIRING PROCEDURE

D.O.L. STARTER

TECHNICAL DATA 10120HW40X

BARE PUMP PARTS

TABLE 1 - TORQUE

ESPECIFICATION FOR BOLTS

HP 4.3/4" ring kit

Upper gasket kit

HP 90 mm valve plate kit

LP 4.3/4" cylinder

HP 90 mm cylinder

LP 4.3/4" valve plate kit

LP 4.3/4" valve plate

HP 90 mm valve plate

LP 4.3/4" cylinder cover with breather

LP 4.3/4" cylinder cover

HP 90 mm cylinder cover

LP UNC 3/8" x 1.1/2" head bolt

No. 1 short intercooler

No. 2 long intercooler

Intercooler kit

3/4" nut for intercooler

Intercooler holder

1/4" crankcase breather tube

NPT 1/8" x 1/4" straight connection

1/4" ring kit

1/8" LP ASME safety valve

Connecting rod with needle bearing

Needle bearing

M6 x 1 x 55 Allen hex bolt

HP 5/16" x 1.1/2" Allen hex bolt

BSP 90 3/4" elbow

Straight fitting

Washer kit

HP 1/8" ASME safety valve

No. 3 aftercooler kit

0

02

01

01

02

01

02

02

01

01

01

01

12

01

01

01

04

02

01

01

01

02

01

02

05

06

02

01

01

01

01

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60

61

000.0077-0

830.1001-0/NA

830.1002-0

709.1306-0

709.1308-0

830.0955-0

809.1028-0

809.1027-0

709.1272-0

709.1423-0

709.1424-0

*

709.1322-0/C

709.1322-0/L

709.1322-0

21011004

21029003

830.0340-5

003.0054-3

830.0599-8

022.0177-0

830.1202-0

019.0079-0

013.0752-0

383.0111-0

003.0111-6

60259501

830.1032-0

022.0215-0

830.1099-0

Flywheel

UNC 1/4" x 3/4" head bolt

Flange cover

Crankcase gasket kit

Oil seal

Lock washer and nut kit

33109 bearing

NC 1/2" x 1" head bolt

Flange

32211 bearing

Crankshaft kit

Key

UNF 3/8" x 3" head bolt

Crankshaft counter weight

Auxiliary connecting rod pin kit

Connecting rod

Master connecting rod

Connecting rod inner bushing

Connecting rod bushing

Counter weight with centrifugal mechanism

Counter weight kit with centrifugal mechanism

UNF 5/16" x 1.1/4" Allen head bolt

Crankcase

3/4" oil level sight kit

3/8" plug

Crankcase cover

UNC 5/16" x 3/4" head bolt

3/4" plug

LP 4.3/4" piston

HP 90 mm piston

LP 90 mm ring kit

01

04

01

01

01

01

01

18

01

01

01

01

02

01

02

01

01

02

03

01

01

02

01

01

01

01

06

01

02

01

01

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

709.1307-0

*

20505001

830.1033-0/NA

60082501

830.0932-0

60154502

*

20504001

60154501

830.0933-0

60267503

*

20508005

830.0934-0

30008502

830.0930-0

60152502

60152501

30007001

830.0937-0

*

20501002

830.0775-0

003.0029-2

709.1316-0

*

003.0031-4

60273501

830.1000-0

000.0080-0

CODE

CODE

QTY

QTY

DENOMINATION

DENOMINATION

No.

No.

* Part available in the market - not sold by Schulz

Note:

HP = high pressure LP = low pressure

35 36

27

26

4

25

24

23

22

20

15

11

10

7

5

3

11

8

2

1

4

6

9

21

4

28

18

19

19

17

17

4

32 - 31

30 - 29

16

14

13

11

12

8

A

53

51

T2

T2

T3

T5

T4

T7

T6

43 56

43**

42**

38

41 40

59 37 34

55

39

42

33

33

34 37

34 37

B

T8

T1

T9

T9

T10

T11

51

58

49

50

B

A

32**

47

57

45

44

60

48

46

52

52

13**

61

** See code page 38

54

T7

T10

T11

T6

T9 HP-LP 34/37

HP 37

T5

T8

T4

T3

T2

T1

Position

lbf.in

304

43

8

2

27

11

13

22

56

59

704

70

158

1,215

141

334

19

185

44

264

30

22

34

25.3

80

58.6

8

5.8

18

13

137

101

16

11.7

38

27.8

2.2

1.6

21

15.4

5

3.6

N.m

ft.lb