AIR COMPRESSOR - OWNER'S MANUAL

13

AIR COMPRESSOR - OWNER'S MANUAL

36

BREAK-IN PROCEDURES

4.

After eight hours of running, check the oil level and look for any oil leaks. Turn the compressor off and bleed down the

tank pressure to about 20 psi and open the drain valve to allow all of the moisture to drain from the tank. Allow the pump to

cool and torque the head bolts and the bolts which hold the inner and after cooler.

5.

6.

We recommend that you change your oil after the first 8 hours of operation. This could help remove any small particles in

the pump and will improve the life of the pump.

After the first week of operation follow the guidelines in the MAINTENANCE SCHEDULE.

MAINTENANCE SCHEDULE

THE LIFE OF YOUR COMPRESSOR WILL BE DETERMINED BY HOW IT IS MAINTAINED.

- A clean pump will run cooler, causing less moisture in the tank and lines. Since the cooler the air is, the easier it is to

compress, cleaning of the pump will make the motor and pump run less and save you money.

- A clean air filter will allow you to compress more air per ciyle. A dirty air filter causes the oil from the crankcase to be

sucked up pas the piston rings if happens you get MAJOR problems. First, the oil gets into your air system, mixes with

the water vapor in the lines and creates a

“

mayonnaise

”

that can foul up tools and destroy paint systems with

“

fish

eye

”

. Secondly, the oil becomes baked onto the valve plates where it builds up and cuts the efficiency of the pump

dramatically.

- Clean oil at the proper level in the crankcase is your best insurance against pump failure.

- A dry tank will last many more years than a tank with water sitting in it rusting away metal. The tank is a great heat sink

and will take out the bulk the moisture that is in your air system

.

t

if you drain it

WARNING

DAILY

WEEKLY

MONTHLY

Turn off power before servicing and be sure the air tank is unloaded. These instructions are based on normal operating

conditions. If the compressor is located in an exceedingly dusty area, increase the frequency of all inspections.

- Inspect the compressor visually.

- Check oil level and add some if necessary, before turning the compressor on.

- Drain moisture from the piping system.

- Be sure there is no excessive or unusual vibration or noise.

- Remove and clean intake air filters; do not wash the filter element.

- Check V-belt for tightness. Belt tension should be adjusted to allow approximately 3/8" to 1/2" (9 to 13 mm) deflection with

normal thumb pressure, see Figure page 16.

- Clean cylinders externally, cylinder head, motor, fan blade, tubing, and tank.

- ASME safety valve should be tested manually to see if it is working properly.

- Check entire system for air leakage around fittings, etc by using water and soap lather.

- Check the pressure switch operation.

- Check for oil contamination and change it if necessary.

TECHNICAL DATA 10120HL40X

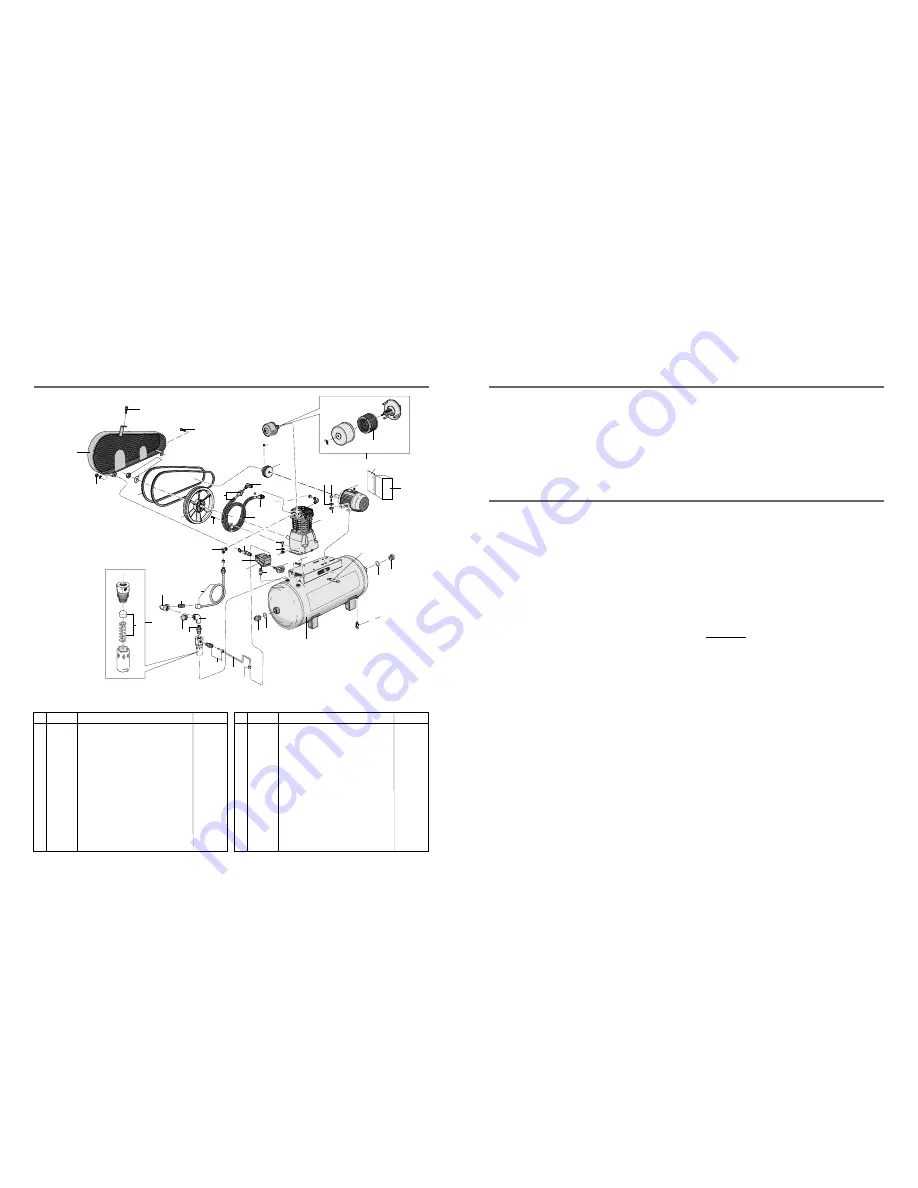

AIR COMPRESSOR PARTS

38

37

36

29

35 23

28

24

13

18

19

16

15

13

12

11

14

7

6

44

20

21

35

34

6

24

3

24

1

2

24

3/8 x 1.1/4 hex head bolt

Bare pump

1/4 ASME safety valve

Pressure gauge

Strain relief

Motor 208/230/460V (three-phase)

Pulley

Start switch**

Support start switch**

Start switch pressure switch cord (not shown)**

Motor start switch cord (not shown)**

3/8 x 1.1/2 hex head bolt

3/8 lock washer

3/8 x 1/2 Allen hex without head

Air filter

Filter element

3/4 plug

3/4 side elbow

BSP 90 3/4 elbow

NPT 3/4 x 3/4 straight connection

1/4 nipple

Hose for tank drain (not shown)

º

CODE

QTY

DENOMINATION

04

01

01

01

01

01

01

01

01

01

01

04

08

01

01

01

01

01

01

02

01

01

No.

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

41

42

43

44

45

4

Belt guard

1/4 hex nut

Belt

Intercooler

NPT 3/4 straight connection

BSP 3/4 elbow

Aftercooler

Check valve

Check valve kit

NPT 1/8 x 1/4 elbow

1/4 Tube

2 Plug

O ring

Pressure switch

120 gal horiz. tank

1/4 tank drain valve

3/4 Nipple

2 x 1 Reduction bushing

Motor fastening plate

3/8 hex nut

1/4 x 3/4 hex head bolt

3/8 Washer

CODE

QTY

DENOMINATION

830.1208-0

*

004.0128-0

709.1663-0

21011002

003.0151-5

709.1667-0

60281501

34004508

003.0005-5

709.1669-0

003.0514-0

023.0339-0

012.0845-0

25003832A

022.0206-0

003.0036-5

003.0512-0

21028503

*

*

*

01

02

02

01

03

03

01

01

01

01

01

01

02

01

01

01

01

01

02

04

02

08

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

*

932.9324-0

022.0057-0

011.0118-0

012.0723-0

015.0602-0

709.1612-0

012.0937-0

701.0379-0

012.0907-0

012.0908-0

*

*

*

809.1086-0

007.0118-0

003.0031-4

003.0343-0

003.0151-5

21011002

003.0033-0

709.1246-0

* Part available in the market - not sold by Schulz. ** Optional start switch

30

22

5

24

24

27

22

10

39

17

41

42

43

21

14

26

9

8

25

31

45