14

AIR COMPRESSOR - OWNER'S MANUAL

AIR COMPRESSOR - OWNER'S MANUAL

35

MAINTENANCE SCHEDULE

SERVICE PROCEDURES

WARNING

!

Never assume a compressor is safe to work on just because it is not operating. It could

restart at any time. Follow all safety precautions and guidelines outlined in this manual.

CRANKCASE OIL -

The oil level should be half way to three quarters up the sight gauge

when the compressor is stopped.

Do not over fill or check the oil level while the pump is running. Compressor must be

level.

Use

, petroleum based, compressor or automotive grade oil

.

Detergent or synthetic oil can damage the pump, cause excessive leaks, and will void

the warranty.

non-detergent

only

DO NOT USE SYNTHETIC OIL IN THIS PUMP !

MAX

MIN

QUARTERLY

ANNUALLY

LUBRICATION

NOTE:

-

-

-

-

Change the air filter element every 300 working hours or quarterly. (Whichever occurs first).

Fasten bolts and nuts as required.

- Change oil more frequently if compressor is located in a very dirty environment.

Test and calibrate the pressure switch, pressure gauge and ASME safety valve according to their own technical

standards. These parts must be removed from the tank and pump to be tested.

Inspect and clean the suction and discharge valve(s) plate(s) every 1000 (one thousand) working hours (whichever

occurs first), located between the cylinder and its cover and, if necessary, replace it (them) according to the operation

conditions.

- The first oil change should be made after 8 hours of operation.

- The second oil change after 40 hours of operation.

- The third and following oil changes should be made after 200 hours of operation, or 60 (sixty) days, whichever occurs

first.

Heavy Duty and multi-viscous oils are not adequate for Schulz air compressor's lubrication. The same applies to oils that

tend to emulsify.

We recommend good industrial oil for air compressors, with rust and oxidation inhibitors and high viscosity level (from 90 to

95), SAE or ISO, as indicated in the table below:

- WHILE RUNNING IN A PERIOD OF ABOUT 100 WORKING HOURS THE OIL LEVEL SHOULD BE CAREFULLY

CHECKED.

Below 32 F

Below 0 C

0

0

32 F to 68 F

0 C to 20 C

0

0

0

0

68 F to 104 F

20 C to 40 C

0

0

0

0

SAE 10W

or

ISO 32

SAE 20W

or

ISO 68

SAE 30

or

ISO 100

AMBIENT TEMPERATURE F ( C)

0

0

RECOMMENDED LUBRICANT OILS FOR SCHULZ AIR PUMPS

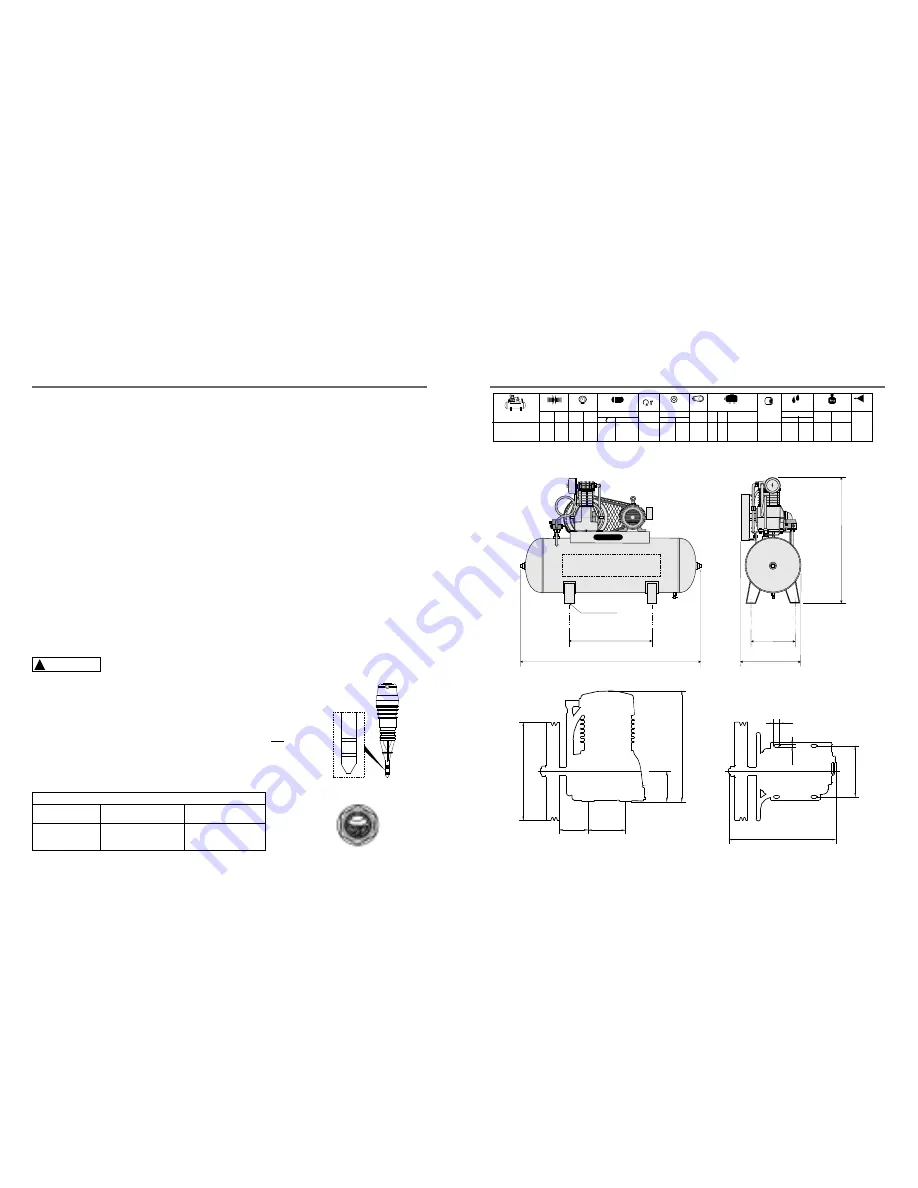

TECHNICAL DATA 10120HL40X

270

Black

(pump)

Gray

(tank)

1,500

ELECTRIC MOTOR

OIL CAP.

WEIGHT WITH MOTOR

DISCHARGE

SIZE

BELT

SIZE

COLOR

REF.

Volume

ml

Kg

2P

2P

VOLTAGE V

[ ]

hp

kW

10120HL40X

150

2-A

1

’’

MODEL

Ø PULLEY

rpm

1,020

5.9

inches

mm

40 1,132 175

12

DISPLACEMENT MAX. PRESSURE

cfm

psig

bar

Geom. Volume

l/min

427

113

TANK

gal

596

lbs

in qt.

1,580

10

Three-phase

208/230/460

7.5

4 x

5/8

”

/16

Ø

47.3/1,200

78.3/1,990

18.4/480

28.7/730

46.5/1,180

19.7/500

4.6/118

7.6/191

5.1/130

19.7/500

1/25,5

0.41/10,5

10.0/255

17.7/451

Note: dimensions in inch/mm.