AIR COMPRESSOR - OWNER'S MANUAL

15

AIR COMPRESSOR - OWNER'S MANUAL

34

VALVES -

on clean dry surfaces

The compressor pump has a set of reed valves manufactured from the highest quality stainless steel. These

valves and the valve plates that hold them in place need to be maintained in order for the pump to work at it's normal

capacity. Once the valves become caked with carbonized dirt and oil they loose their ability to open and close properly and

the amount of air that the compressor can make is dramatically compromised. Before starting this maintenance procedure

you should make sure that you have a set of the gaskets you need to replace when you open up the pump.

1. Remove the air inlet assembly, inter cooler, and after cooler from the cylinder head of the pump.

2. Remove the cylinder head bolts after loosening all of them evenly , from the center out.

3. Remove the cylinder head and valve plates from the cylinder. Separate the head from the valve plates taking care to note

the position of the valve plates for re-assembly. Use caution when separating the parts as the gaskets may be stuck

together. Inspect the condition of the cylinder and piston for damage.

4. Clean the valves and valve plates with a stiff bristle brush or other suitable device. Do not use a steel wire brush as severe

damage may result to the valve seat or valve.

5. Use clean safety solvent to loosen carbon deposits. NEVER use gasoline, thinners or other flammable solutions to clean

valves or related parts. Remove all broken or defective gasket material.

6. To re-assemble the valve plates, a small amount of light grease or petroleum jelly can be used

,

to

hold the reed valves in place while they are assembled. Reserve the order to complete this operation and follow the

recommended torque settings for the head bolts. Use a crosshatch pattem when tightening the head bolts.

7.

Turn the pump over by hand several revolutions to make sure there are no problems. Review the START-UP

CHECKLIST and follow the recommended BREAK-IN PROCEDURES. Re-torque the head bolts and check for leaks

after one hour of running.

MAINTENANCE SCHEDULE

CAUTION

!

Never attempt to change or fill the oil while the compressor is running. Do not work on the

pump while it is hot as some parts of the pump can cause severe burns to unprotected skin.

Never use flammable solvents to clean the pump or the intake system.

AIR FILTER

DRAIN THE TANK

- To service the air filter, remove the wing nut and cover that hold the element on to the intake assembly. Inspect

the element and clean or replace as needed. Paper filters can be tapped out and back flushed with low-pressure air several

times before they must be replace. Fiber (Micronite) filters can be washed out with soapy water, rinsed, and reused until the

element material starts to deteriorate. Never use solvents to clean the filter or inlet parts. Always keep extra filter elements

on hand. NEVER RUN THE COMPRESSOR WITHOUTA FILTER. Clean all parts and re-assemble in reverse order.

To drain the moisture from the tank you should first reduce the air pressure in the tank and air lines to a

safe pressure, around 20 psi. Open the drain valve and drain the moisture into a suitable container for disposal. All piston

pumps have some level of oil bypass the rings and get pumped into the tank. This oil is measured in parts per million (PPM)

and mixes with the moisture in the tank to form a whitish

“

mayonnaise

”

like substance.

Check with local codes concerning the discharge of this fluid directly into the sewer system.

Compressors used in commercial applications should be drained at least once a day. If you only run your compressor

occasionally, it should be drained after each time you use it. Shops that run multiple shifts a day should have automatic

drains to help reduce the moisture build up in the tank. A 5 HP compressor can dump as much as a gallon of moisture a day

into the tank.

-

Change the oil when the compressor is warm so that the oil will drain out of the crankcase easier. Carefully open the plug on

the crankcase drain, open the ball valve and drain the oil into a suitable container. Remove the crankcase fill plug to make

the oil flow out faster. Allow the crankcase to drain completely. Replace the plug, and fill the crankcase to the proper level.

Check the level carefully after the first day of use. Please recycle the used oil.

TECHNICAL DATA 7.580HV30X

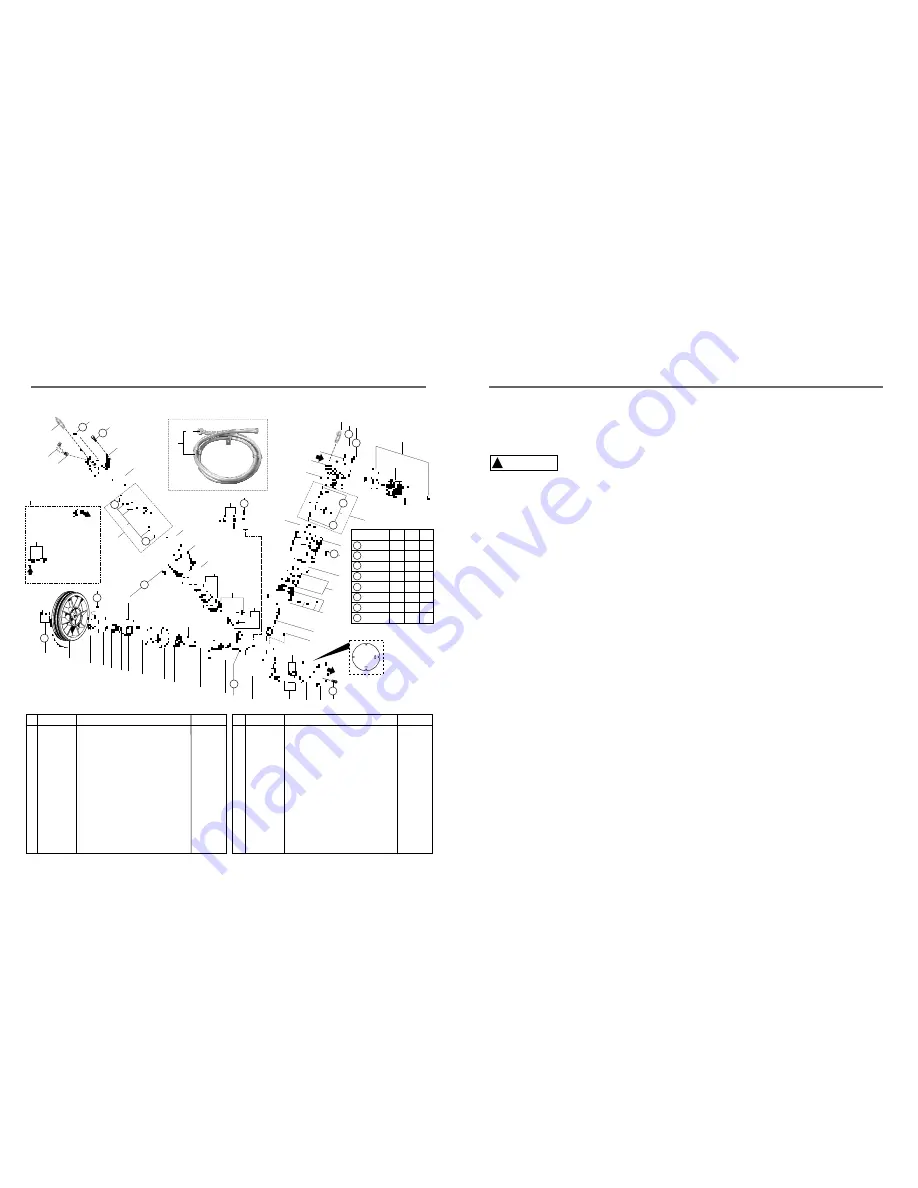

BARE PUMP PARTS

8

47

9

5

10

11

31

30

32

33

1

12

13

14

16

17

19

18

15

5

5

34

25

25

20

21

25

25

26

24

27

46

7

29

5

22

23

24

47

39

41

42

38

DETAIL OF THE

ASSEMBLY OF

GASKET IN A

CRANKCASE

COVER

1

4

5

6

3

2

37

36

35

43

44

38

40

28

1

27

Upper gasket kit

LP 120mm cylinder cover

M6 x 1,0 x 55 Allen head bolt

Air filter

Filter element

HP connecting rod with needle bearing

Needle bearing

HP Ø 2.1/2" piston

HP 2.1/2" ring kit

HP 2.1/2" cylinder

HP 2.1/2" valve plate

HP valve plate kit

HP 2.1/2" cylinder cover

Intercooler kit

90 MF 3/4" elbow

UNC 5/16" x 5/8" LT head bolt

3/4" x 3/4" straight connection

3/4" nut for intercooler

Crankase breather tube

NPT 1/8" x 1/4" elbow

HP 1/8" ASME safety valve

LP 1/8" ASME safety valve

UNC 3/8" x 1" LT head bolt

0

01

01

03

01

01

01

01

01

01

01

01

01

01

01

02

01

02

02

01

02

01

01

14

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

830.0956-0/NA

709.1272-0

*

809.1085-0

007.0118-0

830.0632-0

019.0028-0

830.0608-0

830.0982-0

709.1193-0

809.1029-0

830.0957-0

709.1389-0

709.0283-4

003.0111-6

*

21011002

21011004

830.0340-5

003.0005-5

022.0215-0

022.0177-0

*

Crankshaft

Flywheel

UNC 1/4" x 3/4" LT head bolt

Flange cover

Crankcase gasket kit

Oil seal

UNC 3/8" x 1.1/2" LT head bolt

6208 bearing

Flange

6309 bearing

Key

Counter weight

UNC 3/16" x 7/8" LT Allen head bolt

Crankcase

Oil drain tube

Crankcase cover

3/4" oil level sight

1/4" plug

LP connecting rod

LP Ø 120mm piston

LP 120mm ring kit

LP 120mm cylinder

LP 120mm valve plate

LP valve plate kit

01

01

08

01

01

01

11

01

01

01

01

01

02

01

01

01

01

01

01

01

01

01

01

01

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

830.0609-9

709.1277-0

*

709.0139-0

830.0954-0/NA

023.0099-0

*

019.0006-4

709.1221-0

382.0028-3

709.0147-1

709.0930-8

013.0467-4

709.1191-0

830.0205-0

709.1273-0

830.0775-0

003.0028-4

709.0732-1

016.0004-4

830.0981-0

709.1192-0

809.1028-0

830.0955-0

CODE

CODE

QTY

QTY

DENOMINATION

DENOMINATION

No.

No.

A

A

B

TABLE 1 - TORQUE

ESPECIFICATION FOR BOLTS

T7

T6

T5

T8

T4

T3

T2

T1

Position

lbf.in

ft.lb

304

25

7 - 47

141

11.8

27

19

1.6

LP-HP 24 - 36

44

3.6

LP 24

70

5.8

3

149

12

41

1,128

94

1

63

5

13

34

16

2.2

5

8

17

127

7.2

N.m

45

7

T1

T2

T3

T3

T1

T8

B

T3

T2

T1

T4

T1

3

T5

T7

T6

T5

* Part available in the market - not sold by Schulz.

HP = high pressure LP = low pressure