AIR COMPRESSOR - OWNER'S MANUAL

17

AIR COMPRESSOR - OWNER'S MANUAL

32

TROUBLESHOOTING

Compressor

will not start

No electrical power

Tank pressure is between starting

and stopping pressures

Check or have system checked

Wait until pressure drops

TROUBLE

POSSIBLE CAUSE

CORRECTIVE ACTION

Motor

overheats,

blows fuses

or overload

relay cuts out

Wrong fuse size

Replace with correct size

High ambient temperature

Provide ventilation. Check distance from the wall

Wrong wire size

Have electrical system checked

Thermal overload tripped

Allow to cool and reset overload relay

One leg of supply line interrupted

Check all fuses and terminals for tightness. Check each leg

Pump using

too much oil

Air filter dirty

Clean or replace element

Oil level too high

Do not overfill crankcase

Breather valve malfunctioning

Check valve and fix if broken

Piston rings worn or broken

Ckeck rings and replace if necessary

Oil leaks

Tighten pump bolts or replace leaking gaskets

Wrong oil viscosity, synthetic oil

Drain and refill with proper oil

Tank does not

hold pressure

Diaphagm in pressure switch

defective

Replace pressure switch

Leaking fittings

Check for leaks and tighten

Compressor

starts more

than seven

times per

hour

High moisture level in tank

Drain tank

Check valve leaks

Drain air. Remove and fix

Pressure switch set incorrectly

Check cut in and cut out setting

Excessive air requirements

Decrease shop consumption by installing a regulator. Add another

compressor to supply

Leaks in air system

Inspect air system and fix

Compressor

takes too long

to fill tank

Excessive air requirement

Determine if compressor is properly sized for job

Compressor not in optimal condition

Perform maintenance, check for loose belts, dirty air filter

Dirty, sticking or damaged valves

Remove cylinder head and clean, replace damaged reed

valves and gaskets

Compressor not properly installed

Level the tank feet with vibration isolators and shims

Compressor

vibrates

Mounting bolts too loose

Torque mounting bolts evenly

Pulley and flywheel mis-aligned

Realign per manual

Belts loose

Tighten per manual

TECHNICAL DATA 7.580VV30X

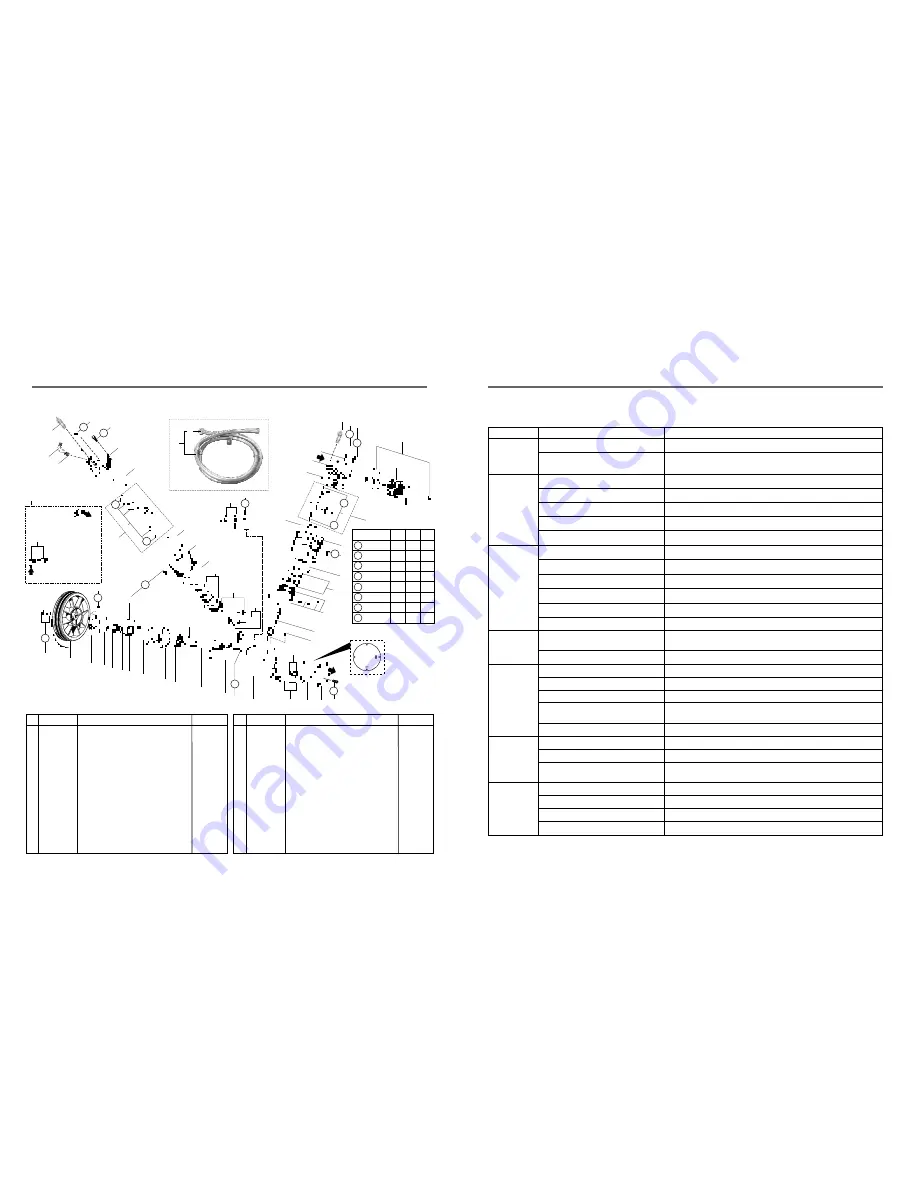

BARE PUMP PARTS

8

47

9

5

10

11

31

30

32

33

1

12

13

14

16

17

19

18

15

5

5

34

25

25

20

21

25

25

26

24

27

46

7

29

5

22

23

24

47

39

41

42

38

DETAIL OF THE

ASSEMBLY OF

GASKET IN A

CRANKCASE

COVER

1

4

5

6

3

2

37

36

35

43

44

38

40

28

1

27

Upper gasket kit

LP 120mm cylinder cover

M6 x 1,0 x 55 Allen head bolt

Air filter

Filter element

HP connecting rod with needle bearing

Needle bearing

HP Ø 2.1/2" piston

HP 2.1/2" ring kit

HP 2.1/2" cylinder

HP 2.1/2" valve plate

HP valve plate kit

HP 2.1/2" cylinder cover

Intercooler kit

90 MF 3/4" elbow

UNC 5/16" x 5/8" LT head bolt

3/4" x 3/4" straight connection

3/4" nut for intercooler

Crankase breather tube

NPT 1/8" x 1/4" elbow

HP 1/8" ASME safety valve

LP 1/8" ASME safety valve

UNC 3/8" x 1" LT head bolt

0

01

01

03

01

01

01

01

01

01

01

01

01

01

01

02

01

02

02

01

02

01

01

14

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

830.0956-0/NA

709.1272-0

*

809.1085-0

007.0118-0

830.0632-0

019.0028-0

830.0608-0

830.0982-0

709.1193-0

809.1029-0

830.0957-0

709.1389-0

709.0283-4

003.0111-6

*

21011002

21011004

830.0340-5

003.0005-5

022.0215-0

022.0177-0

*

Crankshaft

Flywheel

UNC 1/4" x 3/4" LT head bolt

Flange cover

Crankcase gasket kit

Oil seal

UNC 3/8" x 1.1/2" LT head bolt

6208 bearing

Flange

6309 bearing

Key

Counter weight

UNC 3/16" x 7/8" LT Allen head bolt

Crankcase

Oil drain tube

Crankcase cover

3/4" oil level sight

1/4" plug

LP connecting rod

LP Ø 120mm piston

LP 120mm ring kit

LP 120mm cylinder

LP 120mm valve plate

LP valve plate kit

01

01

08

01

01

01

11

01

01

01

01

01

02

01

01

01

01

01

01

01

01

01

01

01

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

830.0609-9

709.1277-0

*

709.0139-0

830.0954-0/NA

023.0099-0

*

019.0006-4

709.1221-0

382.0028-3

709.0147-1

709.0930-8

013.0467-4

709.1191-0

830.0205-0

709.1273-0

830.0775-0

003.0028-4

709.0732-1

016.0004-4

830.0981-0

709.1192-0

809.1028-0

830.0955-0

CODE

CODE

QTY

QTY

DENOMINATION

DENOMINATION

No.

No.

A

A

B

TABLE 1 - TORQUE

ESPECIFICATION FOR BOLTS

T7

T6

T5

T8

T4

T3

T2

T1

Position

lbf.in

ft.lb

304

25

7 - 47

141

11.8

27

19

1.6

LP-HP 24 - 36

44

3.6

LP 24

70

5.8

3

149

12

41

1,128

94

1

63

5

13

34

16

2.2

5

8

17

127

7.2

N.m

45

7

T1

T2

T3

T3

T1

T8

B

T3

T2

T1

T4

T1

3

T5

T7

T6

T5

* Part available in the market - not sold by Schulz.

HP = high pressure LP = low pressure