18

AIR COMPRESSOR - OWNER'S MANUAL

AIR COMPRESSOR - OWNER'S MANUAL

31

TROUBLESHOOTING

Oil in

discharge

air

Compressor air intake restricted

Excessive oil in the cranckcase

Clean or replace filter element

Drain level to mid sight glass/dipstick, see Figure page 14

TROUBLE

POSSIBLE CAUSE

CORRECTIVE ACTION

Wrong oil viscosity

Drain pump and refill with the proper oil

Worn rings

Replace rings

Crankcase breather valve sticking

Clean or replace

Water in the

cranckcase

Oil appears

milky

Compressor not running long

enough to vaporize the water

Allow the compressor to run enough each day to vaporize

the water

Compressor

leaks down

when off

Pressure switch diaphragm leaking

Replace pressure switch

Check valve leaking

Drain tank, remove, clean and check valve. Replace if defective

Fitting or valve leaking

Check for leaks and fix problem

LIMITED WARRANTY

Limited Warranty

Where to repair product under Warranty

What is covered under Warranty

What is not covered by Warranty

Bare Pumps and Air Compressors manufactured by SCHULZ are warranted to be free from defects in material and

workmanship under normal use for a period of 2 years on the pumps and 1 year on the remaining items, from date of

purchase of the end user, except the Contractor Line of Products and all Gasoline Engine driven products. The warranty on

contractor/engine driven models is 3 months. A proof of purchase must be provided by the user to recelve service under

warranty. This warranty is extended to original purchaser for use of the SCHULZ product (only) and is not transferable.

Only the Schulz Authorized Retail Store where the product was pruchased can provide warranty services. Any service

performed by a non authorized service person, voids the warranty. Engines must be taken to the proper factory authorized

service center, I.e. Briggs & Stratton, Honda, Kohler, Robin.

Materials, parts and labor to repair the product are covered by this warranty. For products of 5HP and over, travel/mileage

expenses are allowed. See limitations.

Defects and damages from failure to perform factory suggested maintenance, wrong application, excessive wear and tear

and rental use. Freight is not covered under warranty. Any loss of

“

shop time

”

is not covered by this warranty. Warranty is not

to be considered a free maintenance program.

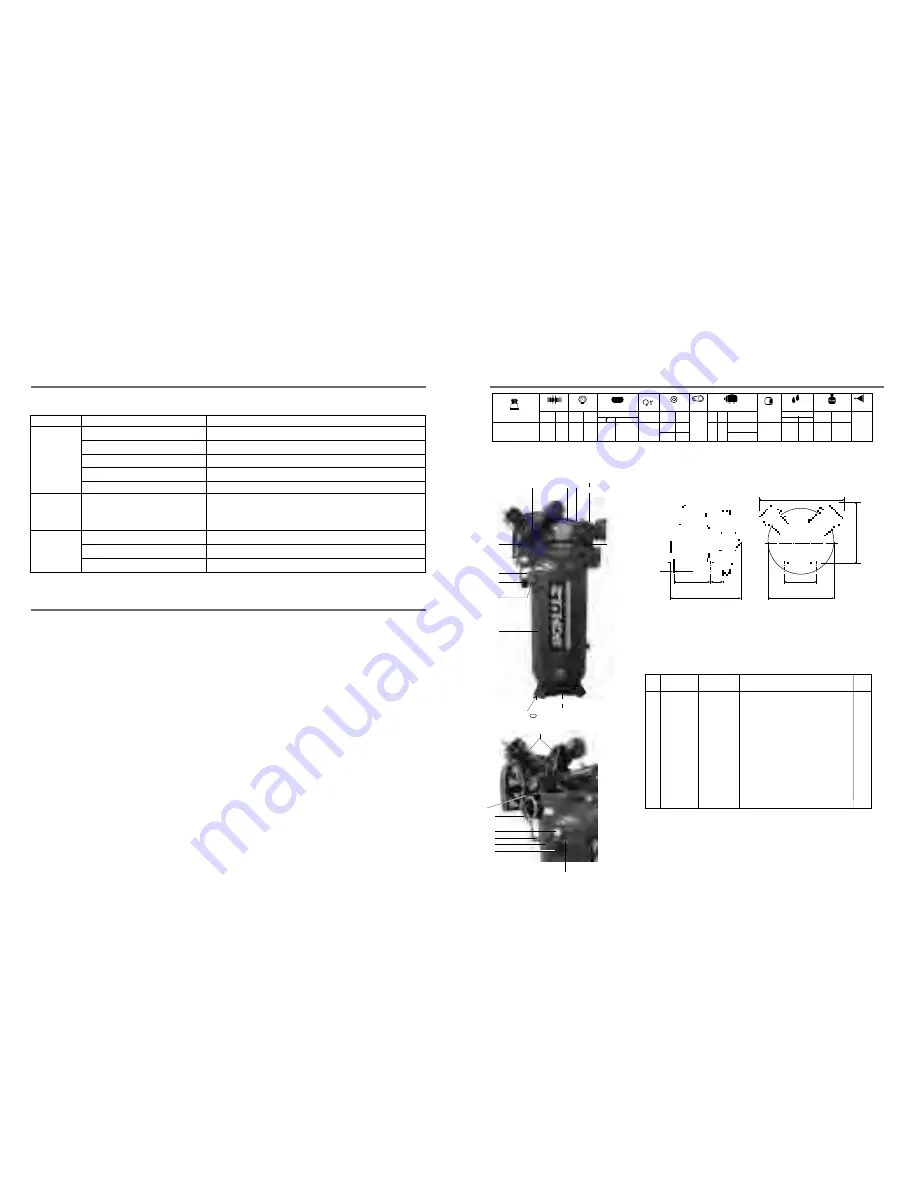

TECHNICAL DATA 7.580VV30X

Compressor dimension (inch/mm)

Height = 74.8/1,900, lenght = 39.3/1,000, width = 25.2 / 640

230

Black

(pump)

Gray

(tank)

230

0,880

ELECTRIC MOTOR

OIL CAP.

WEIGHT WITH MOTOR

DISCHARGE

SIZE

BELT

SIZE

COLOR

REF.

Volume

ml

Kg

Single-phase

VOLTAGE V]

[

hp

kW

7.580VV30X

226

2-A

1/2

’’

MODEL

Ø PULLEY

rpm

960

9.0

inches

mm

30

850

175

12

DISPLACEMENT MAX. PRESSURE

cfm

psig

bar

Geom. Volume

l/min

300

80

TANK

gal

508

lbs

in qt.

0,920

7.5

Three-phase

208/230/460

5.6

Note: dimensions in inch/mm.

Bare pump

Belt guard

Aftercooller

Pressure switch

Pressure gauge

1/4 tube

Check valve

1/4 ASME safety valve

80 gal vertical tank

1/4 tank drain valve

Hose for tank drain (not shown)

Motor 208/230/460V 2P

Motor 230V 4P

Pulley 4P

Pulley 2P

Belt

3/8 x 1.1/4 hex head

3/8 x 1.1/2 hex head

3/8 hex nut

1/4 niple

CODE

single-phase

Q

TY

DENOMINATION

-

830.1222-0

709.1657-0

012.0845-0

011.0114-0

709.1650-0

022.0213-0

022.0162-0

25003775A

022.0206-0

709.1246-0

-

015.0616-0

709.0928-0

-

004.0125-0

*

*

*

003.0174-4

01

01

01

01

01

01

01

01

01

01

01

01

01

01

01

02

04

04

04

01

No.

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

CODE

three-phase

-

830.1222-0

709.1657-0

012.0845-0

011.0114-0

709.1650-0

022.0213-0

022.0162-0

25003775A

022.0206-0

709.1246-0

015.0583-0

-

-

709.1661-0

004.0110-0

*

*

*

003.0174-4

* Part available in the market - not sold by Schulz.

17

1

2

18

3

1

19

AIR COMPRESSOR PARTS

115

4.5

580/22.8

Ø 10.5/0.41

410/16.1

200/7.9

420/16.5

220/8.7

75/3.0

435/17.1

16

12

13

14

15

5

4

20

9

5

7

6

4

8

10

11

4 x 5/8 x 1.1 / 16 x 28 equidistant

90 in the 11.0/280 radius

º