_________________________________________________________________________________________

schunk.com

XND.00033.002_B – 05/2022

34

10.4

Removing and replacing parts

Release cylinder screws and remove the jaws.

Clean and oil the contact surfaces, e.g. with MOTOREX Supergliss 68 K to ISO VG 68.

Place the swivel- and adapter plate and tighten the cylinder screws to 60 Nm.

10.5

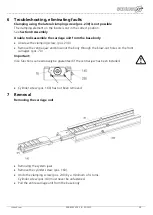

Fitting the 6-fold reversible jaws

Determine the mounting positions of the 6-fold reversible jaws.

The best clamping results are achieved when clamping parts as far out as possible.

Move the cover screws so that the selected clamping position is available.

Position the 6-fold reversible jaws and loosely insert the cylinder screws.

Turn the 6-fold reversible jaws to the required clamping surface and slightly pre-clamp the

workpiece so that the clamping faces are parallel to the workpiece.

Use a torque of 80 Nm to tighten the cylinder screws of the 6-fold reversible jaws.

Important:

When the clamping faces of the 6-fold reversible jaws are not aligned parallel to the

workpiece surface it is possible that the 6-fold reversible jaw becomes loose through the

clamping force

.

11

Aluminium jaws

The aluminium jaws are designed for producing workpiece-specific clamping contours.

In order to achieve maximum precision of the contour, it is recommended that the

contour milling be carried out with pre-clamping of the aluminium jaws. For this purpose,

a narrow spacer piece can be clamped at the bottom and the pre-clamped aluminium

jaws can then be milled to achieve the desired clamping contour.

In view of the fact that clamping may be carried out in different ways, the setting-up

technician is responsible for ensuring that adequate clamping cross sections exist

and that the workpiece is safely clamped.