_________________________________________________________________________________________

schunk.com

XND.00033.002_B – 05/2022

25

3.1.2

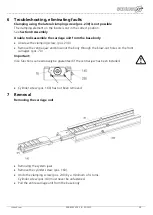

Setting up the third-hand function

Insert the workpiece and move the jaws together so that rear jaw

B

is at 2–4 mm from the

workpiece.

Tighten the lateral clamping screw (pos. 230) to 15 Nm.

Exceeding the clamping torque by 15 Nm may lead to damage on the clamping unit.

3.1.3

Clamping process

By clamping the rear carriage that has been pre-tensioned using a spring, it is possible to

guarantee that when you close the vice, the front clamping jaw

A

is guided to the workpiece

first where it pre-tensions to around 500 N. After the front jaw

A

comes into contact with the

workpiece, the rear clamping jaw

B

starts to close. Once both workpieces have been

clamped, the last step is to completely apply the entire clamping torque.

When opening the clamping jaws the workpiece at the rear clamping jaw

B

is released before

the workpiece at the front clamping jaw

A

is released (after the third-hand function has fully

retracted).

4

Operation (standard operation)

4.1

Clamping / aligning

Push parts of the entire carriage unit from the base body to attach the vice.

For this purpose, see

Section 7 Removal and Section 8 Assembly

.

Important:

The base body and entire carriage must not be interchanged.

The parts have been manufactured together and are not interchangeable.

A

B