_________________________________________________________________________________________

schunk.com

XND.00033.002_B – 05/2022

26

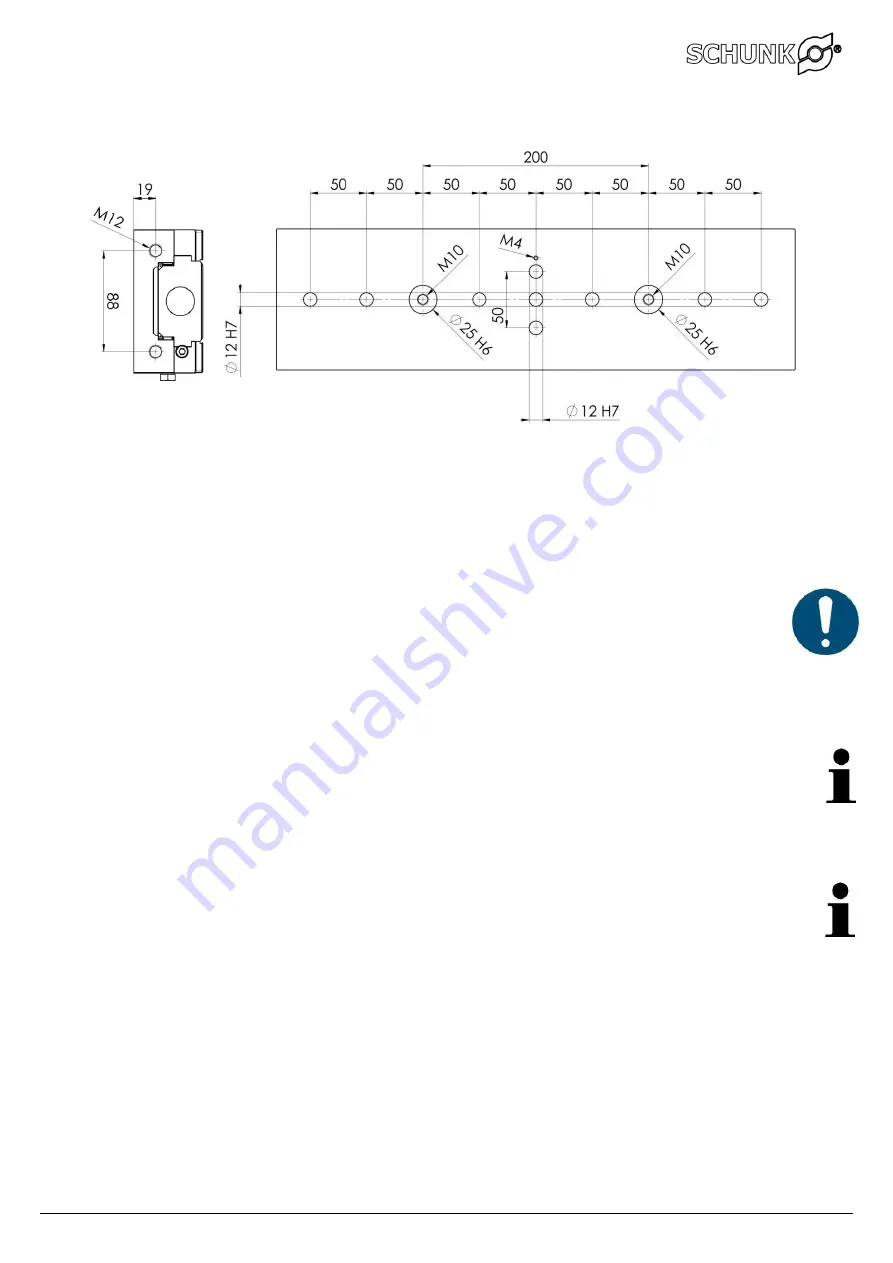

The KSC-D offers a host of attachment options on the supporting table that have all been

integrated into the device.

(Illustration of principle: KSC-D 125 L-460)

The following interfaces are included in the basic variant:

Positioning holes Ø12 H7 to align the vice.

Positioning holes Ø12 H7 so the vice can be positioned and secured to grid plates with a size 50

and on T-slot tables using fitting screws Ø12 f7/M12 or cylinder screws M12.

Locating holes Ø25 H6 for the clamping pin of the VERO-S quick-change palleting system.

Important:

When using VERO-S clamping bolts, make sure that a shortened screw is used, otherwise

the slide may be damage. (See Schunk catalogue)

Longitudinal grooves to attach clamping claws.

Attachment thread M4 in the base body for alignment using alignment and centring sets.

Threads M12 at the front on reference surface.

The KSC-D can also be produced at the factory with customer-specific positioning and fixing

holes as well as with location recesses for various commonly available quick-change palleting

systems.

4.2

Corrosion

The KSC-D's base body has been nickel-plated. Carriages and jaws are made of steel. Well-

maintained coolant is necessary to guarantee ideal functionality which must demonstrate

specified concentrations,

pH values and conductivity properties.

Deviations from manufacturer data may lead to a formation of corrosion.

4.3

Jaw range

The reliable function of the clamping device is significantly affected by the selection of the

correct top jaws.

4.4

Jaw change

Release cylinder screws and remove the jaws.

Clean and oil the contact surfaces, e.g. with MOTOREX Supergliss 68 K to ISO VG 68.

Changing the jaws or moving them in the carriages, tightened the cylinder screw (12.9) with a

torque of 60 Nm.