Assembly and Settings

03.00 | CLM | Assembly and operating manual | en | 389015

17

4 Assembly and Settings

Assembly measures

• When mounting the module and when mounting loads, do not

allow impermissible forces and moments to be exerted (

☞

catalog data)

• Select the suitable screw tightening torque when mounting the

module or loads on the module in accordance with the

generally accepted guidelines for screw connections.

• Secure all screw connections using a suitable chemical screw

lock.

4.1 Mechanical connection

Evenness of the

mounting surface

The values apply to the whole mounting surface to which the

product is mounted.

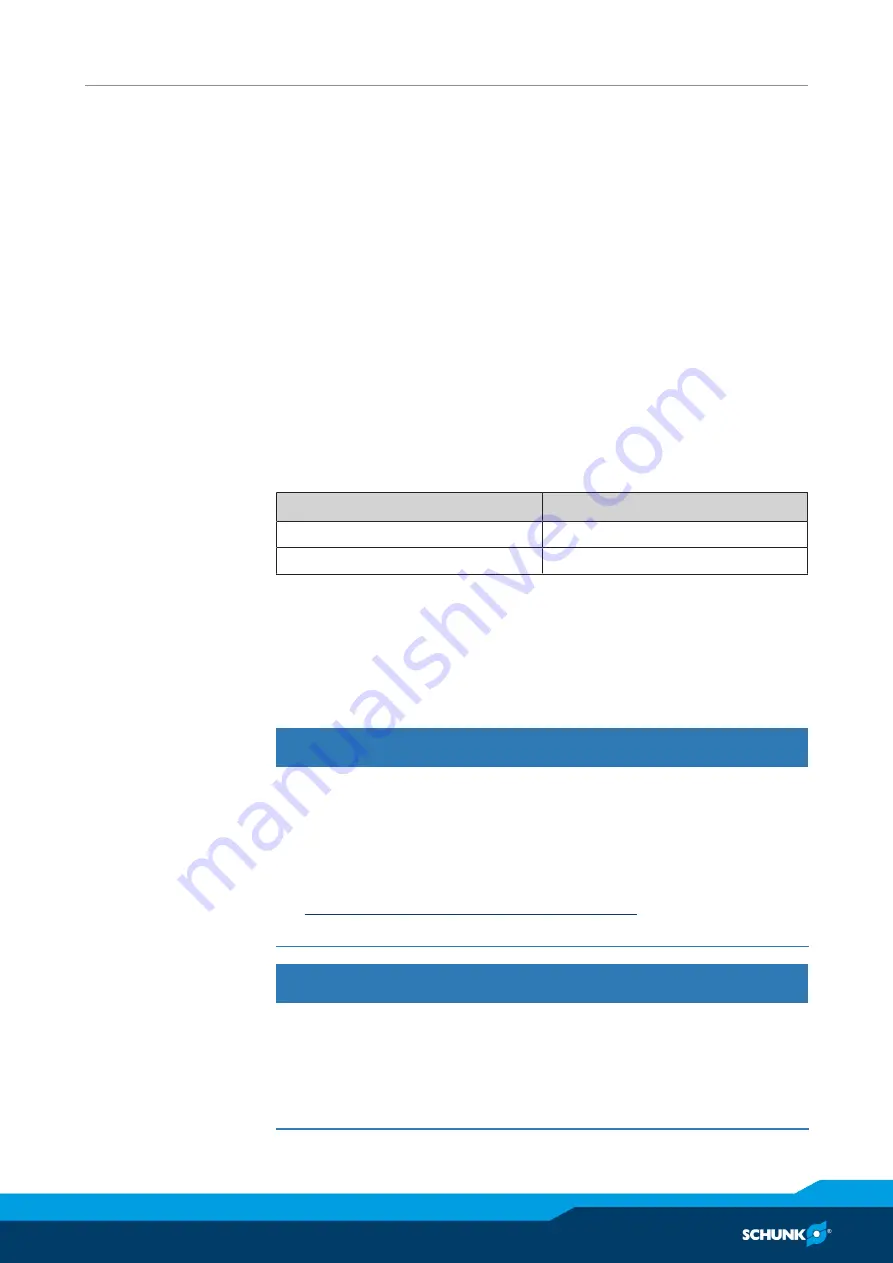

Requirements for evenness of the mounting surface (Dimensions in mm)

Edge length

Permissible unevenness

< 100

< 0.02

> 100

< 0.05

The linear module may be selectively attached to the body or the

carriage..

Similarly, the structure may be optionally attached to the end

carriage or the base body.

4.2 Pneumatic connection

CAUTION

Possible damage to the linear module!

If the unit moves too hard into the end position, the linear

module may be damaged.

•

A linear movement must always be free of impact and bounce.

•

For this purpose, carry out sufficient throttling and damping,

Adjustment of the shock absorber strocke

•

Observe the specifications in the catalog data sheet.

CAUTION

Risk of damage to the linear module when changing pressure

medium.

The unit must not under any circumstances be operated with

oiled air before operation with unoiled air (washing out of factory

lubrication).