General

8

25.00 | DPZ-plus | Assembly and Operating Manual | en | 389035

1.1.4 Variants

This operating manual applies to the following variations:

• DPZ-plus without gripping force maintenance

• DPZ-plus with gripping force maintenance "O.D. gripping" (AS)

• DPZ-plus with gripping force maintenance "I.D. gripping" (IS)

• DPZ-plus force intensification (KVZ)

• DPZ-plus ATEX (EX)

• DPZ-plus high-temperature (V/HT)

1.2 Warranty

If the product is used as intended, the warranty is valid for 24

months from the ex-works delivery date under the following

conditions:

• Observe the specified maintenance and lubrication intervals

• Observe the ambient conditions and operating conditions

Parts touching the workpiece and wear parts are not included in

the warranty.

1.3 Scope of delivery

The scope of delivery includes

• Sealed 3-finger centric gripper DPZ-plus in the ordered model

• Accessory pack

Content of the accessory pack:

• 6 x Centering sleeves for mounting

• 2 x O-ring for hose-free direct connection

• 2 x screw plug for hose connection

• 2 x cylindrical pin for mounting

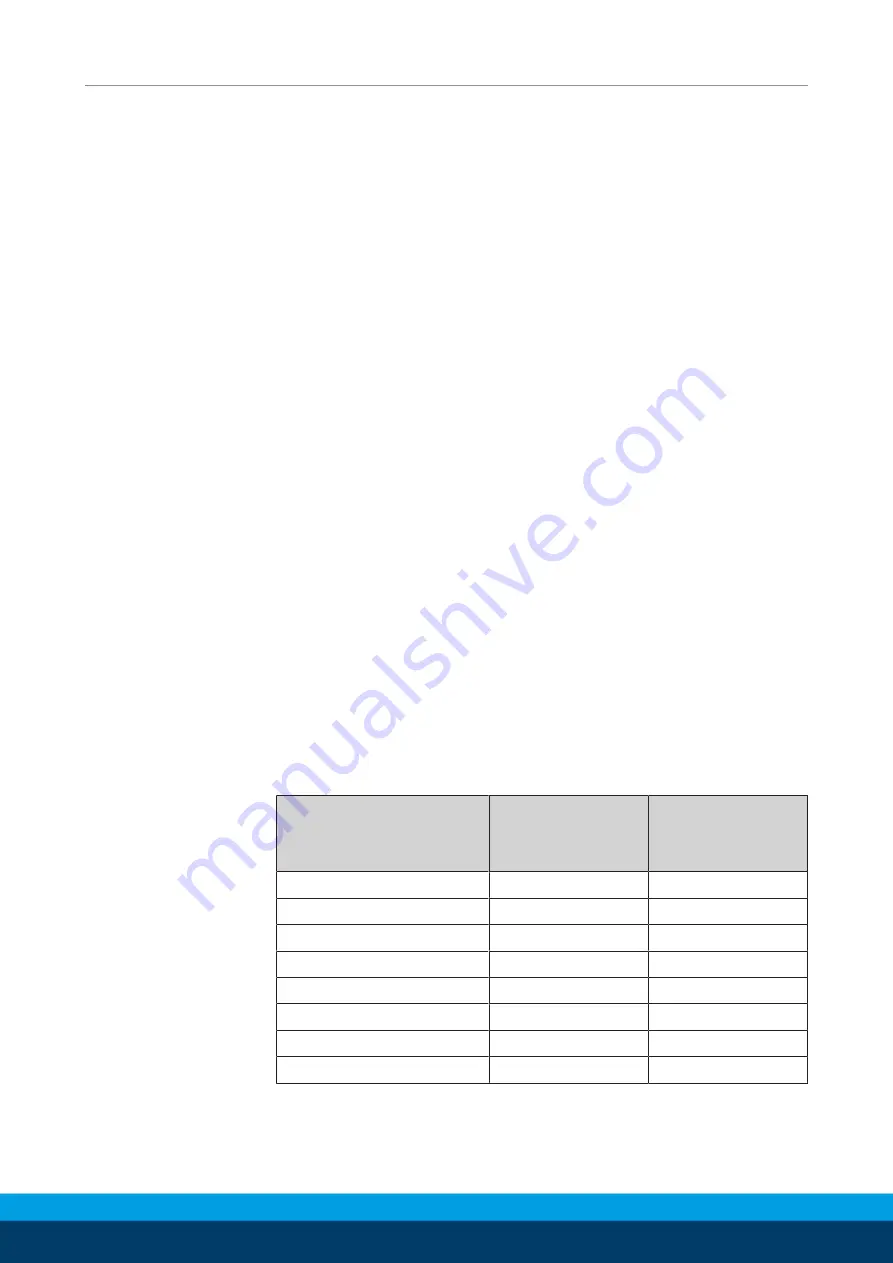

ID.-No. of the accessory pack

Accessory pack for

ID number

ID number

high-temperature

(V/HT)

DPZ-plus 40

5521694

5521695

DPZ-plus 50

5520796

395520796

DPZ-plus64

5515333

395515333

DPZ-plus 80

5515334

395515334

DPZ-plus 100

5515335

395515335

DPZ-plus 125

5515336

395515336

DPZ-plus 160

5515337

395515337

DPZ-plus 200

5515338

395515338