Maintenance

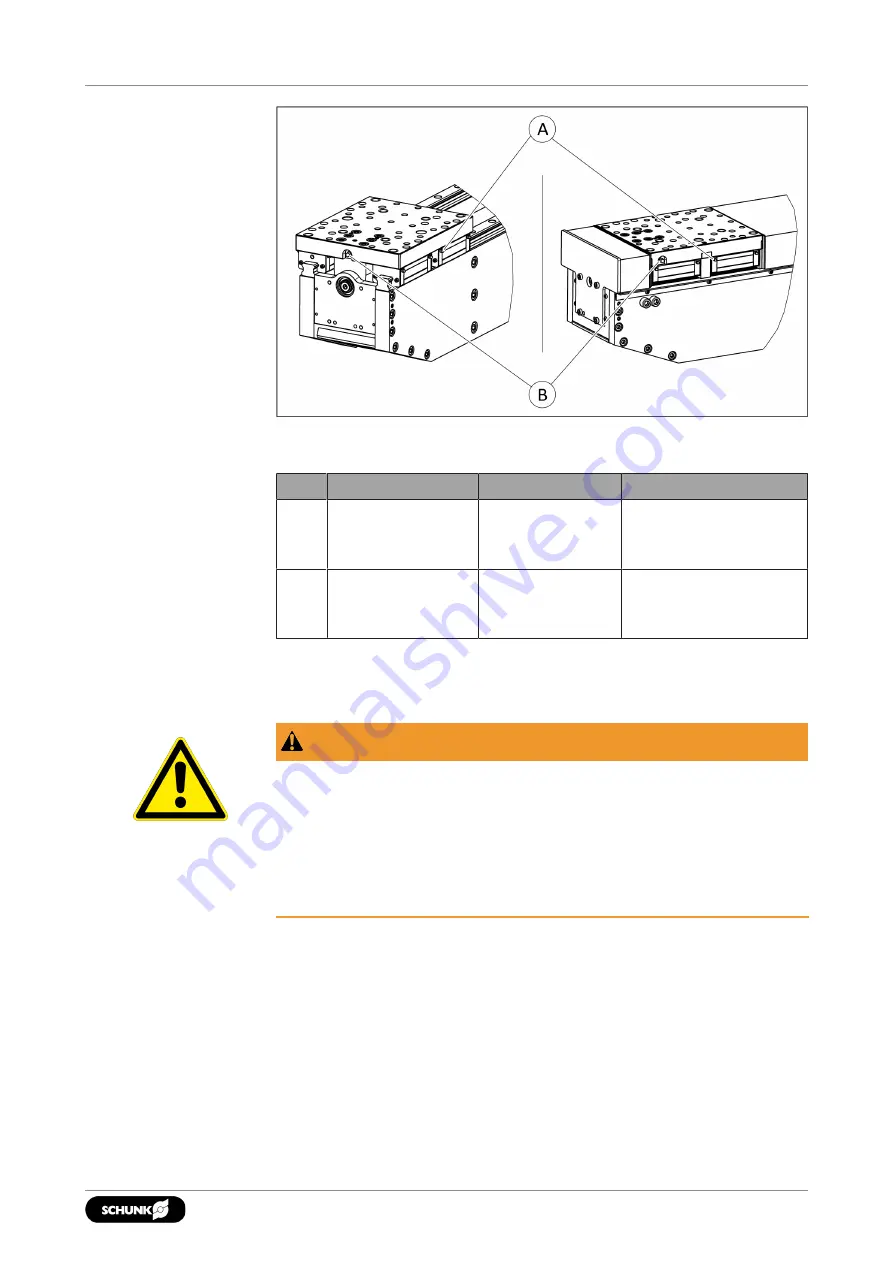

Greasing areas per slide

Left

: Without bellows /

Right

: With bellows option

Item Lubricant point

Lubricant

Lubrication nipple

A

Linear ball guide

(1x for each guide

carriage)

AFC grease (THK) THK PB107 (ELG 30 &

75),

THK A-M6F (ELG 120)

B

Spindle (1x per

base jaw)

Klüber Microlube

GBU Y131 or

Dynalub 510

Conical lubrication

nipple DIN 71412

(SCHUNK ID 9936303)

Observe the manufacturer's safety data sheets!

9.3 Lubricate product

WARNING

Risk of injury due to moving parts!

When moving the gripper fingers, body parts may get squashed/

hit causing severe injuries.

•

Do not interfere with moving parts during operation.

•

Observe position and direction of movement of the gripper

fingers.

1. Supply the spindle and linear ball guides with grease via the

2. Completely open and close the gripper alternately.

9.4 Servomotor/brake maintenance

The documentation for the respective components contains

information on the maintenance work,

33

01.00 | ELG | Assembly and Operating Manual | en | 1527393

Summary of Contents for ELG 120

Page 39: ......