Design and description

02.00 | EMH | Assembly and Operating Manual | en | 1393220

17

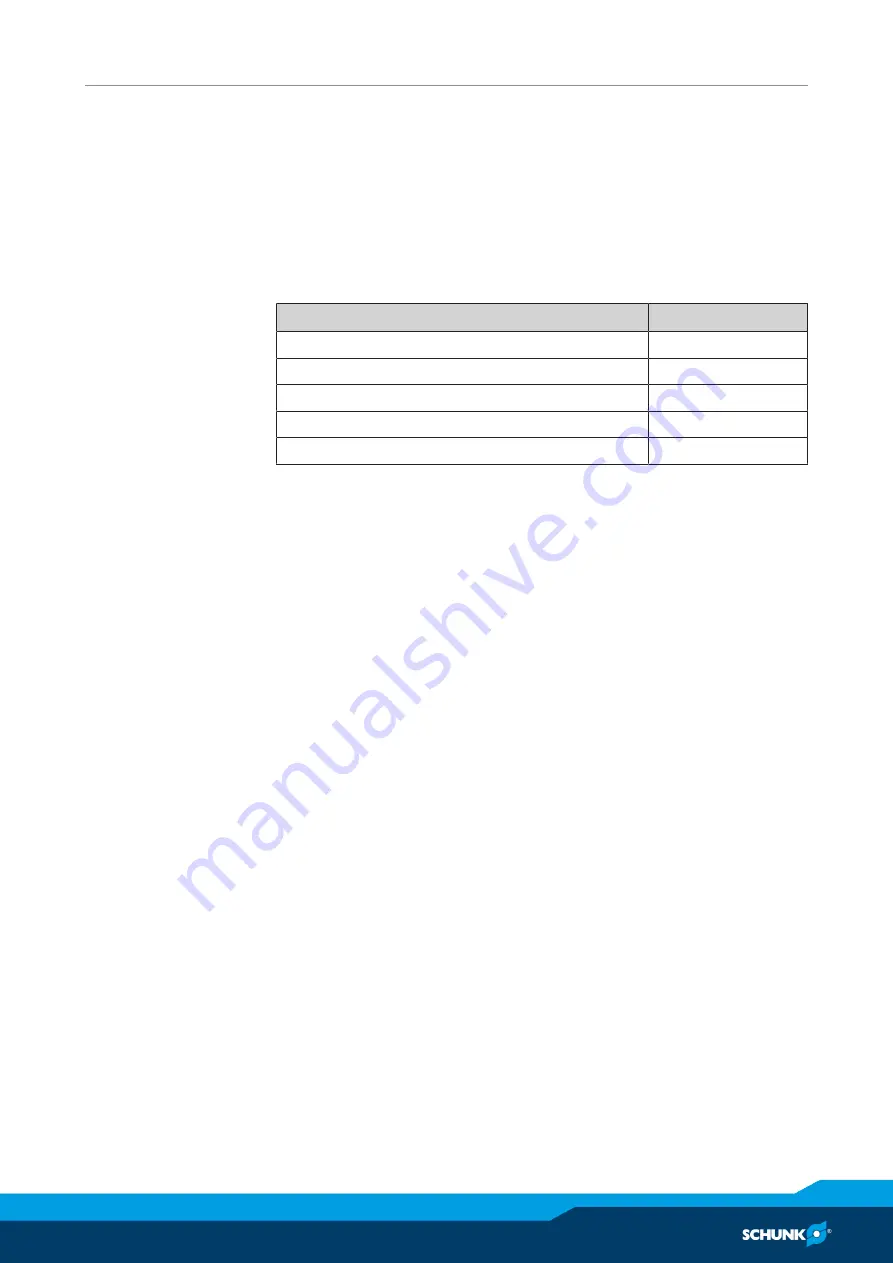

4.3 Magnetic suitability of the workpiece material

The product is design to hold almost all ferromagnetic materials.

The attainable holding force depends on the magnetic resistance

and thus on the chemical composition of the respective workpiece

material, among other factors. Accordingly, with some

ferromagnetic materials a reduction in the nominal holding force

of more than 30% can be expected.

The following table shows a few examples of empirical values:

Material

Efficiency

Conventional steel (Fe 360)

100%

Ferromagnetic crude steel (C10 – C15)

90%

Tool, case hardening and sectional steels

70 - 80%

Magnetic stainless steel

65%

Cast iron

50%

In addition, material alloys can cause residual magnetism to

remain in the workpiece, which significantly reduces the holding

force.

Negative impact of heat treatment processes

Heat treatment processes can substantially change the magnetic

characteristics of a ferromagnetic material. When methods suchas

forging, hardening, tempering or sintering are used, the suitability

of the treated workpiece needs to be tested separately.

Examples of unsuitable materials

Handling workpieces made of materials such as the following is

not possible:

• Aluminum and its alloys

• Bronze

• Brass

• Non-magnetic cast iron

• Some stainless steels (e.g. austenitic), which are only slightly

magnetizable after being hardened by plastic deformation.

• Non-metallic materials

Note:

if you have questions about the magnetic suitability of a

workpiece, contact SCHUNK.