_________________________________________________________________________________________

www.schunk.de

XND.00018.002_A – 10/2018

23

4

Operation (standard operation)

4.1

Clamping / aligning

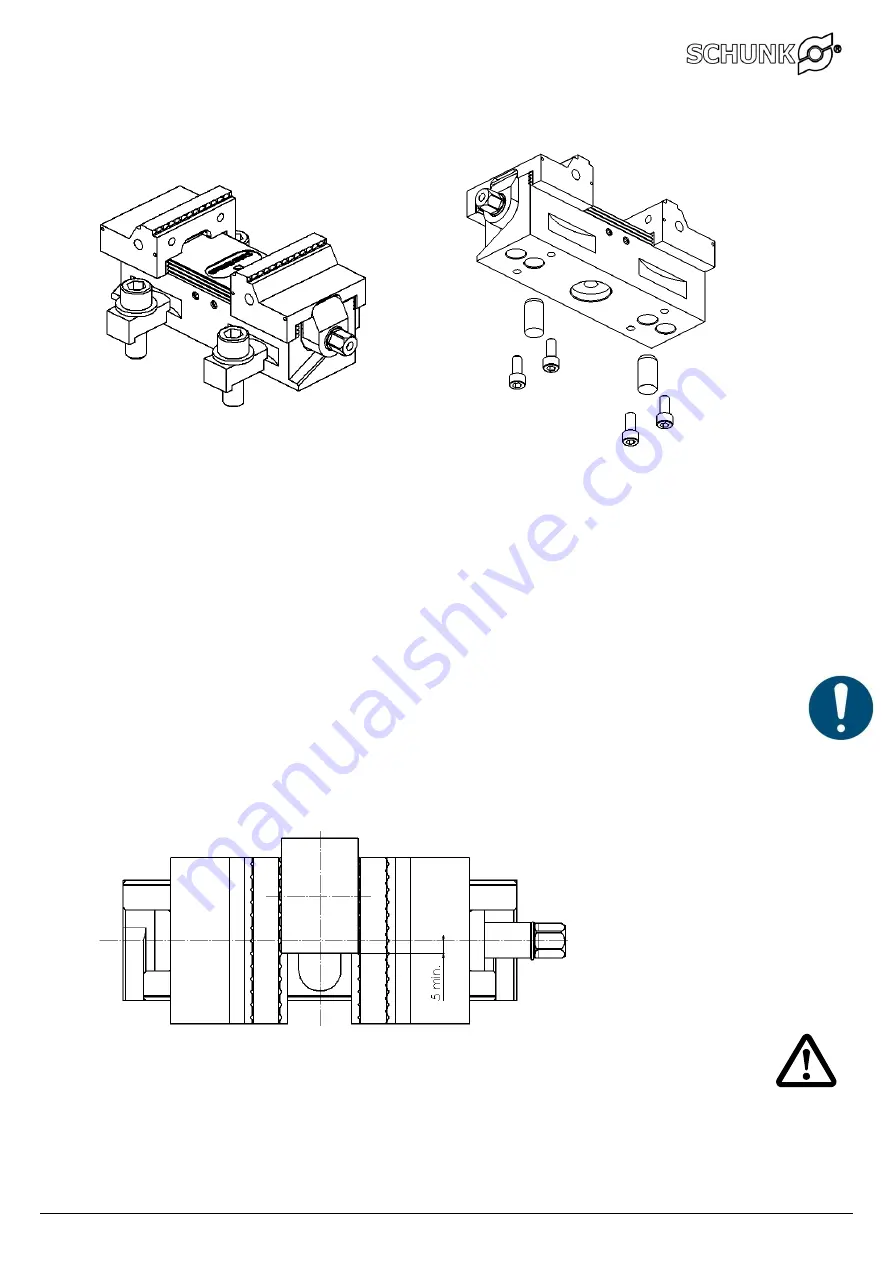

The basic versions of the KSC2 65 and KSC2 40 include 2 x Ø12 H7 and 2x Ø8 H7 positioning

holes respectively, which can be used to position the KSC2 65 on grid plates with

50 mm division and the KSC2 40 on grid plates with 30 mm division, and on T-slot tables.

The KSC2 is attached from above using four M12 bolts and clamping claws.

Alternatively it is also possible to attach the KSC2 from below using four M6 bolts.

The base plate is fitted with an interface to attaching the clamping bolt for the VERO-S quick-

change palleting system and the indexing pin.

Important

:

The KSC2 40 does not have an interface for the Vero-S zero point clamping

system.

The cylinder screw for VERO-S is too long and must be shortened to max. 42 mm.

The KSC2 can also be produced at the factory with customer-specific positioning and fixing

holes as well as with location recesses for various commonly available zero point clamping

systems.

In order to ensure the correct function of the vice, the workpiece must be clamped

at least 5 mm above the vice's symmetrical axis.

4.2

Jaw range

The reliability of the clamping device function depends significantly on the correct selection of

jaws.